Styrofoam ceiling tiles are one of the most popular materials for interior decoration. It attracts consumers not only affordable price, but also the vast opportunities that this decoration opens up in terms of creating an elegant and original interior. Another factor in favor of choosing ceiling panels made of polystyrene foam is the simplicity of its installation. Repairs can be done without much effort with your own hands, without involving workers on the ad.

Features of ceiling tile material

Expanded polystyrene ceiling tiles are well-known in private and industrial construction. This is an inexpensive type of finish, which is made from light and environmentally friendly raw materials. The basis is foam, pressed from small balls, with a diameter of up to 1 mm. Due to this, the coating structure looks smooth and uniform. Expanded polystyrene tiles are well suited for decoration of premises of various purposes - residential and auxiliary rooms in apartments, summer houses and private houses, offices and studios, museums and galleries.

The modern market offers consumers polystyrene foam tiles made in various colors, sizes and textures.

To choose the ceiling decoration to the style of the room, you can choose a product that mimics the following materials:

- snow-white modeling;

- whitewash;

- natural stone;

- leather;

- the cloth;

- wood;

- brick;

- carbon.

Products are lightweight and easy to process. It will not be difficult to choose the right model, perfect for decorating any interior. Moreover, polystyrene tiles look good on walls, along with the decoration function, performing the task of warming the surface. When laying from floor to ceiling, such a coating looks impressive and representative.

Types of ceiling tiles made of expanded polystyrene

The industry produces square, rhomboid and hexagonal tiles. The size is considered to be standard 50x50 cm, but rectangular products of 40x60 cm can be found. The coating thickness is 6-14 cm, depending on the type and purpose.

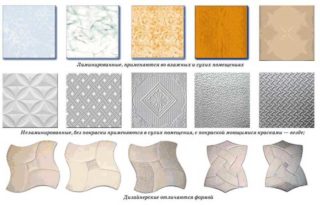

In the manufacture of tiles, the following technologies are used:

- Pressing. The shape and size of the raw materials are attached using stamping. Finished products have a raised surface and a small thickness of up to 8 mm. Since the front side is not covered with a protective film, it is recommended to treat it with impregnation or paint. Otherwise, the foam will darken over time and may become stained.

- Extrusion. The heated polymer mass is passed through the slots, while a protective film is applied that simulates one of natural or artificial materials. Tiles are characterized by a small thickness (3 mm), density, resistance to moisture and mechanical stress. She does not need additional design, since she herself is part of the interior.

- Injection Raw materials are baked under pressure, as a result of which the final product acquires strength and water resistance. Such tiles are thick and embossed, they can be washed and painted.

The edges of the panels can be smooth and stepped. The second option is more expensive, but allows you to create an almost seamless surface that looks even and monolithic.

Advantages and disadvantages

Like any other finish, polystyrene tiles have their advantages and disadvantages.

The advantages include:

- affordable cost;

- light weight;

- ease of installation;

- ease of care;

- flexibility to trim areas with slight bends;

- good insulating qualities;

- water resistant.

Cons of foam products:

- the need for careful alignment of the base, which takes time and money;

- the material does not allow air to pass through, so there should be effective ventilation in the room;

- brittle polystyrene crumbles upon rough handling;

- the presence of joints that spoil the impression of the finished ceiling and walls.

The material remains popular, as it allows you to quickly, inexpensively and beautifully design a room of any type.

Sticking technique

Tiles on the ceiling will look aesthetically pleasing only if they precisely observe the technology of their fastening.

First you need to prepare such tools and materials:

- level, tape measure, clerical knife;

- spatula, miter box, grater;

- paint brush or roller;

- hacksaw for metal;

- long steel ruler, pencil;

- tile adhesive, putty, primer, paint.

Since the work will not be done at height, you will need to buy or rent a stepladder. Respiratory organs are protected by a respirator, and hands are protected by gloves.

After this, preparation of the base is carried out.

This process consists of the following steps:

- Dismantling. Lighting fixtures, wiring and baseboards are removed from the ceiling. All unstable fragments of the old finish are removed. Stains of grease, mold, rust streaks are removed. Dust and dirt are washed off from the ceiling.

- Alignment. It is carried out with cement mortar or starting putty. After drying, the composition is polished using a grater.

- Primer. The surface is covered with a solution several times until it ceases to be absorbed. It is advisable to add an antiseptic to the primer.

You can glue polystyrene foam on the ceiling diagonally, in even or offset rows.

Installation is carried out in the following sequence:

- Drawing a marking.

- Kneading the glue. You can use the finished composition in tubes.

- Application of the solution on the tile. It is better to apply it with a line at the edges and a few points in the middle.

- Applying fragments to the ceiling in accordance with the markup. They must be pressed tightly to the base. Protruding glue should be removed immediately.

- Skirting the surface. It is advisable to use lamellas of one with tiles composition and texture.

After the adhesive has completely hardened, the coating can be painted. An additional coating will protect the foam from mechanical damage, give it a presentable appearance, make the cleaning procedure easier and faster. For work, it is advisable to use water-based or acrylic paints that do not dissolve the polymer.

Tile purchase calculation

Material requirements can be calculated in several ways.

The first option involves measuring the ceiling area and dividing the result by 0.25 (the area of one tile). The resulting number is rounded up to one.

Another method is to measure each side, increasing the length and width to an index multiple of 0.5 and dividing the result by 0.5. Then the numbers are multiplied.

When laying with a diagonal, it is necessary to add 20-25% of the material to the resulting number based on fitting along the walls.

Criteria for choosing a ceiling tile

Since the ceiling plays a large role in the design, the choice of material for its decoration must be approached thoughtfully and responsibly.

You should pay attention to such details:

- evenness of shape and edges;

- material structure;

- uniformity of thickness and density;

- clarity of the picture;

- originality of design;

- Colour.

It is better not to spare time and money, but to buy a quality product, which is accompanied by a certificate of conformity.

Styrofoam Ceiling Tile Manufacturers

On sale are products of domestic and foreign manufacturers. Considering that it is manufactured using the same technology and the same equipment, the quality of the tiles is practically the same.

Attention should be paid to such trademarks:

- Lagon;

- Nitram CIN;

- VTM format;

- Sorex;

- Romstar

- Baikal;

- AFM;

- Armstrong

The tiles of these manufacturers are distinguished by accuracy of forms, original design and long service life.