When installing or reconstructing heating communications, it is necessary to mount new ones or replace old units. Work in the presence of tools and skills can be done independently. The main thing is to understand how the binding of heating radiators occurs, choose its scheme and materials.

Definition of Battery Harness

Under the binding of heating radiators is meant a set of pipeline elements and fittings for connecting radiators to the main. The harness is the most vulnerable communication zone for reasons of disconnection of connections, the likelihood of using poor-quality fittings and the lack of protection from mechanical stress in the circuit.

The principle of connecting the battery to the pipeline is not important, the efficiency and reliability depends on the selected circuit. The simplest horizontal technology is stable, when using the lateral method, you need to calculate the financial costs.

To lift the system from the floor, special metal tubes are used - they increase the reliability of the strapping.

The need for heating pipes

The binding of heating batteries ensures the correct operation of all elements of the heating main, the timeliness of their adjustment. Works also solve problems:

- choosing a method of control over the system - manual or automatic;

- normalization of the functions of heating communications - the flow of coolant in a separate area is limited;

- reduction of expenses for utility bills;

- safety of the finished system, which is not clogged with sediment and debris;

- ensuring normal temperature and protection against pressure fluctuations;

- removal of air jams from communications;

- adjust the heating rate of heating devices;

- the possibility of connecting different circuits, their settings;

- quality of heat distribution by batteries.

Tying elements need to be selected with the condition of their maximum heating.

Varieties of strapping systems

You can connect heating equipment in two ways - single-circuit and double-circuit.

Dual circuit

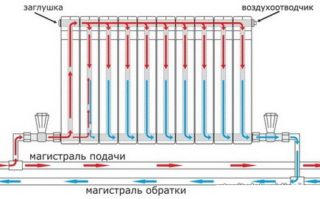

The two-pipe connection method involves the use of 2 types of fittings - for supply and return. In the first case, the heated coolant enters the radiators, in the second case, the cooled water is returned to the tank. Uniform heating of the room is achieved due to the receipt in each battery of the coolant from almost the same temperature.

The advantages of double-circuit strapping include:

- temperature adjustment of each circuit;

- maintaining efficiency, regardless of the floor of the house;

- quick shutdown of a site during repair work or maintenance.

The disadvantages of the two-pipe system are the costs of a large number of consumables, an increased number of solder points.

With proper installation of a dual-circuit system in a private house, its cost will be slightly more expensive than a single-pipe system.

Single circuit wiring

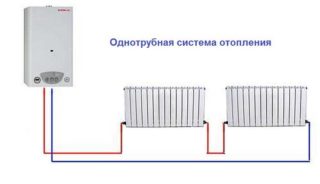

A single pipe connection is a way of supplying all batteries to a single line. Water, heating and cooling, moves along one channel and is supplied to the devices in turn.That is, the heat carrier in the heated state goes up the main riser and is distributed among the devices of each floor, starting from the top.

Single-circuit wiring has several advantages:

- cost savings during installation in a private house;

- use of associated or dead-end water movement;

- reduction in the amount of materials in 2-5 floors;

- the possibility of arrangement with a total length of the highway up to 30 m.

The disadvantages of single-pipe wiring are lower temperatures on the lower floors with a minimum area of radiators without bypasses.

A single-circuit system is suitable for connecting 4 to 5 heating devices.

Popular schemes for connecting heaters to the pipeline

Reliability of installation, the efficiency of heat transfer of batteries depends on the layout of the strapping. There are several ways to connect the system.

Single sided

You need to connect the batteries from the end - the supply and return lines will be on one side of the device. The return line is located at the bottom, and the flow is brought up. When performing this scheme, the heat transfer of radiators is used to the maximum. In order to mask the fittings, it is possible to supply at the bottom, and return to the top, but this will reduce heat production by almost 30%.

Diagonal

The scheme provides for the organization of return flow from below on one side, and supply from above to the other. The diagonal technology is implemented for sectional batteries from 12 cells and panel batteries from 120 cm. The method ensures uniform heating of devices in the zone farthest from the highway.

Lower

The return and supply lines are connected at the bottom, which allows you to hide the pipeline. The circuit has differences depending on the type of battery:

- Sectional appliances. The supply pipe is connected at the bottom on one side of the battery, the return pipe is discharged to the other side.

- Panel steel devices. All pipes are located at the bottom of the battery - the supply from the collector goes up, and the return is directed to the collector below.

The lower connection reduces the heat efficiency of sectional appliances by 20%.

- Side

- Diagonal

- Lower

Selection of accessories for strapping

You can bind the system using the following elements:

- locking elements - standard ball valves;

- plugs overlapping other channels;

- Mayevsky cranes for air release at the time of seasonal launch;

- sealants - special compositions or tapes.

- Stopcock

- Mayevsky crane

- Caps for radiators

To control the quality of communications, install:

- pressure gauge for checking the pressure level in the pipes;

- manual or automatic temperature controller, which allows you to set the radiator to a specific temperature.

When performing polypropylene strapping, a special welding machine is needed.

Rules for the selection of elements of control-locking and adjusting type

Do-it-yourself connection of radiators to the heating system involves the use of throttle and shut-off elements. The type of fittings depends on the number of communication loops. For a single-circuit line, you will need:

- ball valves for turning off radiators - 2 pcs .;

- Mayevsky's crane for air release;

- bypass with valve;

- chokes or thermostat valves for temperature control - may not be used;

- automatic air vents.

A flush valve is also used for the diagonal design, but it can be replaced with a standard ball valve. When performing double-loop strapping, an inductor is additionally used. That is, for one radiator, you need a thermostat on the underwater pipe, a throttle on the return and a flushing valve with a diagonal connection.

How to make polypropylene strapping

The polypropylene type of pipe is made of an elastic and durable copolymer. Manufacturers produce products up to 125 mm in diameter, which are not subject to deformation when water freezes, and are resistant to acidic conditions, mechanical damage.

Tying with polypropylene for heating batteries is carried out according to the soldering technology:

- They start connecting the pipeline after the installation of radiators, expansion tanks, boilers, columns.

- The fittings are cut with special scissors at a vertical angle of 90 degrees.

- To prevent deflections and ensure the reliability of the connections, auxiliary hardware is used.

- The connection of polypropylene pipes is carried out with a soldering iron. First, the reinforcement is heated by the apparatus for 5-10 seconds, after which the elements are combined with each other.

- For reliable fixation, pipes are laid aside for 3-4 minutes.

The depth of the weld, the time of connection, heating and cooling depend on the diameter of the pipes and are indicated in the table.

| Diameter mm | Weld, mm | Time, sec | ||

| Heating | Connections | Cool down | ||

| 20 | 14 | 6 | 4 | 2 |

| 25 | 16 | 7 | 4 | 2 |

| 32 | 18 | 8 | 6 | 4 |

| 40 | 20 | 12 | 6 | 4 |

| 50 | 23 | 18 | 6 | 4 |

| 63 | 26 | 24 | 8 | 6 |

The optimum temperature of the soldering iron for working with polyethylene fittings is 260 degrees.

The quality of the connection, the energy efficiency of the system and the efficiency of the coolant flow depend on the selection of the radiator strapping scheme. When performing strapping work, you need to use a good check-valve and special tools.