The boiler has a large weight due to the water tank placed inside. It is important to know how to hang the boiler on a wall so that the mount can withstand a heavy unit. Models of water heaters are fixed with the same sequence of actions, the method of hanging is determined by the material of the wall on which the heat exchanger will be located.

Types of Water Heaters

Boilers are classified based on the type of energy used and the principle of action. The storage unit contains inside a tank with a heating element, in which a given volume of water is heated. The advantages are durability and economical operation, and the disadvantages are manifested in the large weight, dimensions and the need to wait for the heating of the liquid.

Water heaters are:

- electric;

- gas;

- indirect heating.

Flowing models heat water before entering the mixer. Such a model is mounted on a water pipe and works as a heat exchanger, letting fluid through in an arbitrary flow. Cold water is heated to boiling water in a few seconds and hot tap enters the tap.

Gas

Gas-fired boilers are almost always flow-through and contain a heat exchanger made of copper flat elements that transfer energy to the water tube. Burners are located under the heater and transfer heat to the plates. The collector of used gases is located above the heat exchanger, collects them and directs them to the chimney by means of natural draft or forced ventilation.

In obsolete models, the burner is ignited with a piezoelectric element or match, the latest options include an electric ignition device. Boilers have a closed or open combustion chamber, depending on the method of air intake.

Electric

A heat source in the form of a heating element is placed inside or under the integrated water tank. The water tank is protected by a heat-insulating layer of foam or polyurethane and a casing. On the front there is a control panel for adjusting the temperature.

Heated water in the tank is replaced by cold when disassembled from the tap. If the supply of warm liquid runs out, you need to wait until the device warms up. The sensor coordinates the temperature and turns on the heater when the indicator drops below the established norm.

- Gas boiler

- Electric boiler

Indirect heating

The equipment operates in winter from the energy generated by the heating boiler using gas, electricity or coal. The unit supplies hot water to several water outlets, due to its high capacity. It is a cylindrical tank made of metal, protected by thermal insulation.

Inside the tank is:

- a heat exchanger in the form of a coil (tube) through which antifreeze or water from the heating system flows;

- magnesium anode to protect the inside from corrosion;

- a thermostat to coordinate temperature and start;

- hazardous pressure protection valve.

Models are floor and wall. The vertical version is used in everyday life, and horizontal units are installed to heat a large amount of water.

Mount Options

The heat exchanger is fixed on the wall with the help of l-shaped hooks to put on the mounting bracket for the boiler on the back of the unit. A gap of 12 - 20 cm is left between the appliance and the ceiling. An additional frame is made if the water heater is mounted on a wall of weak materials.

An insert into the water main is made anywhere using pipes made of metal-plastic or propylene. Connection to the power grid is carried out using an automatic machine (bag).

How to mount a boiler on the walls of different materials

The boiler is mounted to the wall practically according to the same scheme, regardless of the design and dimensions, but there are differences.

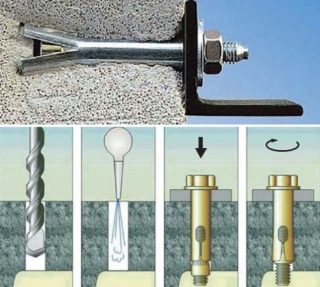

- The metal anchor for the boiler is driven into vertical rails using a special gun - this is a reliable but time-consuming method. Not every owner has the necessary tool and you need to rent, borrow or purchase a new one for one-time installation.

- Metal dowels are used, which are fixed in the tips of plastic. Reliability is somewhat reduced, but this method is easier. Holes are drilled in the monolith of the wall, plastic casings are inserted and the L-shaped dowels are screwed in to hang the unit.

Foam concrete

Spiral nylon dowels are used to attach lightweight water heaters with a capacity of up to 50 liters to a wall of aerated concrete foam blocks. Heavy aggregates of 80 - 100 l are fixed using the mounting for a boiler with a metal tip.

A steel plate is used, which is fixed with steel studs threaded through the thickness of the wall. On the reverse side of the partition, the nuts are tightened, and the dowels for the boiler are attached to the plate. There is a mounting option using chemical or adhesive anchors that hold securely in the wall.

Adobe

In partitions made of this material, it is not enough to drive steel anchors. A special metal shield is used for hitching, which transfers the load from the water heater evenly to the entire wall. Hooks are welded to the support for mounting the unit.

The supporting element is attached to the partition in several places. Through threaded pins are used through the wall, nuts with washers are screwed on the reverse side. Studs are welded to the shield or fixed with a bolted connection.

Ceramic tile

If the wall is finished with ceramics, it is possible to mount the heater if there is a fence made of durable material under the lining. The layer on which the tile lies should be a solid mass without voids and not thicker than 3-4 cm. Metal anchors of the correct length are used so that they capture ceramics, mortar and the body of the wall by 10-12 cm. The boiler will break if it is fixed only into a tile with a solution - the layer will separate from the wall.

Plasterboard partitions

It is possible to fix the boiler on drywall, if during the construction of the partition a frame support is made. The embedded element corresponds in size to the size of the heater. A narrow lining will hold the anchors, but a heavy unit will push the drywall along the perimeter of the frame element.

If the gypsum board is glued to a solid wall, the boiler is fastened with anchors through the drywall and the adhesive layer in the thickness of the base. Depth should be sufficient to hold the heat exchanger.

Wood

The installation method in the wall of a wooden house depends on the design of the fence. Solid walls made of logs or beams are durable and can withstand boilers on anchors. Over time, the dowel in the tree becomes loose, so an additional metal plate is placed. It will serve as a support and a non-combustible gasket according to the dimensions of the heater.

In panel wooden buildings, the frame is made of timber, between the supports there is a filling of shingles with insulation. The base shield is installed necessarily and attached to the frame to which the water heater is mounted.

Lining

The material is used for decorative decoration and is not considered as a basis for fixation. A non-combustible gasket is required. An asbestos sheet is placed between the boiler and the lining, if the finish is on a solid foundation.Otherwise, you need a durable shield made of metal, which will provide additional support and fire protection. The shield can be replaced with a frame made of square pipe or another profile.

Plaster

In this material, the dowels and anchors break out, so the plane of the ceiling and floor is used if the ceiling has a solid structure. Vertical racks are fixed on the upper and lower supports, sometimes longitudinal niches in plaster are cut out for them. For fasteners use steel anchors and dowels. Hooks for mounting the heater are welded to the support posts.

Brick and cinder block

The water heater is fastened with an anchor screw to the wall of silicate or red brick, if the thickness of the partition is more than 250 cm. Metal support pads are used if the stones in the wall have a hollow design, with holes of round or rectangular shape. In cinder block partitions, such gaskets are always used, since the strength of the material is inferior to brick.

The boiler is installed in any convenient place on a straight plane or in a corner. You need to know exactly the base material for mounting. Water heaters can have one or two brackets for fixing. For example, the Ariston and Atlant models have an adjustment screw as a third support to the wall. With its help, the boiler is leveled in a level in a vertical plane.

DIY tools and installation

Marks the position of the heater on the fence. The distance from the holes on the bracket to the ceiling and the adjacent wall is measured.

Installation is carried out in 3 stages:

- Linkage to the unit.

- Connection in the water main.

- Power connection.

The boiler is connected to the water supply by a blue and red pipe, through which cold and hot liquid enter. For fastening, connecting fittings are used.

Used tools:

- hammer drill, construction gun, drill;

- roulette, level;

- welding machine;

- grinder with a circle for metal;

- set of wrenches;

- plumbing fixture.

Connection of electricity can be done with your own hands. Sometimes it is better to invite an electrician to ensure that the wiring is installed correctly.