Heating boilers Siberia from the Russian plant NMK are considered one of the most reliable and popular devices in comparison with analogues. Solid fuel devices of this brand have their own characteristics, advantages and disadvantages, which you should familiarize yourself with before installation. The Siberia boiler requires special care, therefore, the operating rules of this device must be taken into account.

Features of boilers Siberia

The NMK plant has been operating since 1995 and is based on the territory of Novosibirsk. The heating boiler Siberia is presented in two versions: Hephaestus and KVO. All gas appliances of the series are standard classic units and have a simple design. It includes the boiler itself and the attached water jacket. Due to the minimum number of parts and compact dimensions, devices can be placed in any part of the house.

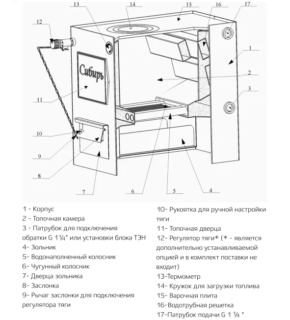

A closer look should pay attention to the grate, cross beams and cover. All Siberian boilers are created by universal technology and consist of almost the same elements. The grill is designed to increase the area of thermal volume and achieve maximum effect. Beams are placed on the path of the movement of flue gases in order to direct heat to the heating system. Covers are supplemented with openings for coal and have a standard shape.

Specifications

Before choosing a suitable boiler model, it is necessary to study its technical characteristics in detail. Each model has its own designation. For example, KVO 12 TPE: the number indicates power, the letters mean a device with an electric heater operating on solid fuel. The thermal performance of the devices is measured in kilowatts and varies between 12-20 kW, the efficiency is 70%, the standard pressure cannot be more than 0.1 MPa. Using devices of both series, it is possible to heat rooms from 120 to 200 m2. The maximum temperature should be at least 95 degrees, the nominal value should fluctuate between 60-80 degrees.

The diameter of the chimney of the Siberia boiler should be 150-200 mm, the power of the unit is 2 kW. Compliance with all technical requirements during installation and operation ensures stable operation of the boiler. As a thermal carrier use drinking water with a value of GOST 2874, the rigidity of which cannot exceed 0.7 mg. The design company should choose the water treatment option. In addition to water, it is allowed to use household heat carriers approved for residential premises.

For safety reasons, it is forbidden to use antifreezes containing ethylene glycol and other liquid components that are not intended for heating systems.

Advantages and disadvantages

Each Siberia heating boiler, regardless of model, has its pros and cons. In the list of advantages, consumers make raw materials of a high level of quality from which the devices are made. The main advantage of the units is also considered their reliability and durability, a large assortment and choice of options, affordable prices and the ability to purchase the right model in each region of the country.

Brand products are able to function properly in all weather conditions, including in extreme heat and frost. The necessary documents are attached to each boiler: certificates of conformity, instructions for use.The standard solid fuel boiler of the Siberia brand has practically no drawbacks, with the exception of minor difficulties in the installation process, which depend on the characteristics of the room.

Types of boilers Siberia

The NMK enterprise produces solid fuel units KVO and Hephaestus. Each series includes a set of models that have their own characteristics, differences, advantages and disadvantages.

Siberia KVO

Steel appliances KVO series are designed for owners of country houses and cottages who are looking for budget units of a household type. The list of devices in the series includes five types, marked with the numbers 10, 12, 15, 20 and 25 by the number of kW of power. All of them are made of heat-resistant steel, part is supplemented by elements of cast iron. Each boiler is supplemented with special details:

- grate-type water tube grill;

- cross beams with heat carrier;

- a lid combined with a hob;

- additional 3 kW heater; installed separately.

Pipes for flue gases, supply and return lines in the models of this series can be located on the right or left wall for more convenient installation. The principle of operation of such boilers does not differ from standard combustion devices, they work on wood or coal, heating the coolant inside the heat exchanger.

Siberia Hephaestus

Hephaestus devices have been manufactured since 2014; they are among the latest in heating equipment. Consumers can purchase a unit of one of three types with a capacity of 15, 20 or 30 kW. The firebox of each boiler is surrounded by a water jacket, the grate is supplemented with a deep ash pan containing a large amount of waste. Boilers of this type have their own characteristics:

- the ability to supply a heater with a capacity of 4 kW as an additional source for heating;

- the presence of supply pipes and reverse type for more convenient strapping and installation work;

- an opportunity to put the regulator for draft of mechanical type;

- reservoirs for water in the grates in order to increase work efficiency.

Double-circuit and single-circuit boilers of the series operate similarly to standard water heating devices. This is a good option in terms of value for money, suitable for those who adhere to the budget when creating a heating system in the room.

Hephaestus boilers are not suitable for severe loads and are lightweight.

DIY installation

The boiler and other elements of the heating system must be installed taking into account the observance of safety rules. The device is mounted at certain distances from combustible elements, observing a distance of at least 500 mm from the walls of the boiler. There must be at least 1200 mm of space from the top of the floor boiler and ceiling, at least 1250 mm of space in front of its door. If a wood or warm floor is made of combustible materials, a fireproof coating is made for it from sheet steel laid on a layer of asbestos cardboard, which is impregnated with a solution of clay.

Valves or safety devices are placed in the part of the output manifold device without intermediate elements. The inlet pipes cannot be less than 32 mm. The heating system is mounted so that the air is completely removed when it is filled, and the coolant is eliminated through the drainage during the emptying of the device. The heater block must be connected using a cable with 30 A circuit breakers, the cross-section of the copper wire in which should be at least 4 mm2.

Operating principle

Due to the simple design, Siberia units can save money and reduce fuel costs. They work on the principle of using a closed firebox, which limits the flow of air into the chamber.By creating the effect of “oxygen starvation” during operation, the fuel burns 3-5 times longer than in standard mode. For one day, only a couple of fuel loads will be enough if firewood is used. Using coal, the boiler is able to work for more than two days.

Siberia boilers have high efficiency, reaching 90% - this is an ideal indicator for solid fuel appliances.

Operation and maintenance

During use of the system, the level of the thermal carrier in the open tank cannot fall below its height. By adding thermal carrier, it is maintained at the optimum level. Water from the heating system cannot be used for domestic purposes, this is fraught with stopping circulation and lowering the liquid level. Before switching on, it is necessary to open the gates in the chimney, check whether the tap is open on the return line, and also take into account the presence of draft.

During ignition, the device is heated with dry wood, loading them into the furnace to half the height. Hot coals should completely cover the grate, the coal is loaded gradually, when the firewood flames perfectly. Coal fuel must be placed in the furnace through the door in small portions, without leaving the hole open for a long time. After the ignition of coal, the ash pan door is left in a position that ensures complete combustion of the fuel. During initial ignition, a dark liquid may flow out from under the ash drawer.

You need to clean the grate at least once a day. A large accumulation of water inside the furnace must not be allowed; cleaning is carried out at least 1-2 times a day.