One of the ways to improve the thermal insulation of the walls being built is to use a brick with insulation inside. It will also help to save on the volume of building materials used and reduce the noise level in the home. Outside, the building will have a presentable appearance due to the use of special types of bricks for facing.

Choice of insulation

The best performance will be possessed by layered masonry using an effective internal insulation. It has a number of requirements. Firstly, in accordance with fire safety standards, the material must be non-combustible. Secondly, it must have a thermal conductivity sufficient to protect the interior at the lowest winter temperatures characteristic of the area. The value of this parameter is indicated on the packaging or in the attached documentation. When comparing with the temperature minimums of the region, you can determine how thick a layer of insulation is required. It is also necessary that the material passes vapor well. Otherwise, water droplets will accumulate in its thickness, and this reduces the thermal conductivity.

Mineral wool

Buildings are insulated with different materials containing mineral fibers. They are produced by centrifuging basalt or glass, previously subjected to melting. Fire resistance and excellent thermal insulation properties make these materials attractive. The latter are due to the porous structure of the insulation. The only drawback of mineral wool is its susceptibility to dampness. Because of this, during installation, you will have to take care of the organization of the waterproofing layer.

Expanded polystyrene

It is used both in sheet form and in the form of granular granules. It does not have fire resistance. When exposed to the wall of open fire, expanded polystyrene melts; after the incident, the dwelling will require restoration with the replacement of the outer layer of brick. The substance is immune to moisture. Another of its advantages is lightness: due to this, it is used when it is impossible to overload the foundation of a building.

Bulk insulation

In the well masonry with insulation, sometimes expanded clay or slag is poured into the lacunae. This move attracts by the simplicity of organization and the cheapness of the material itself. However, in terms of thermal insulation properties, these substances are inferior to mineral wool and expanded polystyrene. Slag embankments, in addition, absorb a lot of water, which also does not contribute to improving performance.

Expanded polystyrene in bulk is good in that it has minimal hygroscopicity.

Types of masonry walls with insulation inside

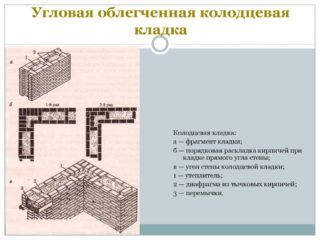

Brickwork with insulation inside can be arranged in one of two ways. In the well method, the material is laid in nodes formed by load-bearing walls and lintels. A masonry method is also used when the insulation is laid out in a continuous layer.

Brickwork with insulation inside can be arranged in one of two ways. In the well method, the material is laid in nodes formed by load-bearing walls and lintels. A masonry method is also used when the insulation is laid out in a continuous layer.

Lightweight masonry

The basis of this design is a pair of brick walls parallel to each other and located at a distance of 0.15-0.3 m. In some places they are interconnected by horizontal surfaces consisting of one row of heat-insulating bricks. They can be equipped with different frequencies (every 0.7-1.2 m of the vertical plane). Gaps from one partition to another are filled with insulation. As a rule, bulk materials are used for this - crushed stone, expanded clay or sand.Having filled the well to half, the embankment must be tamped so that the particles are denser. Some types of heaters are supposed to be coated with concrete mortar and protected from shrinkage with a special reinforcing structure. You can’t leave bare wells in the upper part of the building - they must be closed with several rows of lined bricks. It is permissible to equip an air gap in the thickness of the wall. It can be narrow stripes of empty sections between the walls (no wider than 5-7 cm). They prevent the accumulation of moisture in the insulation. It is recommended to make the layer thickness equal to 2 cm.

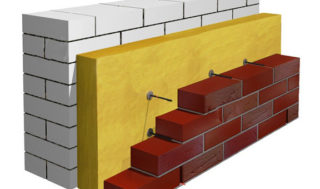

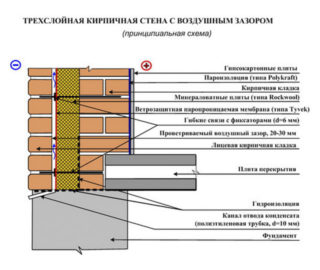

The device is a three-layer wall structure

The design of a three-layer wall made of brick with insulation suggests a gap between the inner (bearing) and front rows. At some intervals, they are connected by reinforcing metal elements. A layer of insulation is laid in the resulting gap. With this design, the inner layer can also be aerated concrete or made of cinder blocks. It implements the supporting function for the roof, as well as for partitions between floors. The thickness of the multilayer wall masonry in 640 with insulation is most often practiced. But the indicator may differ up or down.

The outer wall performs a facing function, creates an attractive appearance, and also protects the insulation material from environmental factors that adversely affect its performance. It is made from special decorative varieties of bricks.

Necessary tools and materials

Before you start laying brick walls with insulation, you need to prepare a drawing, which indicates the relative position of the elements, the main dimensions and distances. You also need to stock up with a sufficient amount of insulation. You can use the table of thermal conductivity of basic materials. The larger the value of this parameter, the thicker the insulation layer should be.

Also for the work you will need the following tools:

- reinforcing mesh;

- container for the mixture;

- waterproofing from rolled bitumen materials;

- construction anchor bolts;

- level;

- putty tool;

- trowel;

- plumb.

It is necessary to stock up on brick for the erection of the wall structures themselves. When three-layer masonry, the facade part is made of special facing varieties.

The technology of building walls with insulation inside

First, a waterproofing cutoff is laid on the foundation, preventing the warming layer from getting wet. Mark the boundaries of the base and produce the masonry of the inner wall. The material used is solid brick. The way of working is traditional for the walls of the bearing type. If the work is carried out in a region with cold winters, the design can be made thicker (one and a half bricks).

First, a waterproofing cutoff is laid on the foundation, preventing the warming layer from getting wet. Mark the boundaries of the base and produce the masonry of the inner wall. The material used is solid brick. The way of working is traditional for the walls of the bearing type. If the work is carried out in a region with cold winters, the design can be made thicker (one and a half bricks).

When the height of the bearing part reaches about a meter, they begin to lay out the outer wall with the facing layer. In this case, observe the distances indicated in the drawing. Between the two walls there should be a space where the insulation will be poured or fastened. They can be connected with brick lintels or reinforcing-anchor bundles.

Having mounted the binder components, they fill up or fix the insulation. If the materials are used in sheet form, they are installed in the gap, and then fastened to the supporting wall using dowel nails with plastic caps. After installing the insulation, they continue laying out the next rows of both walls to a height of 0.6-1.2 m. After that, jumpers and placement of heat-insulating material are again organized. So continue until the walls reach the required height.

Three-layer insulated walls are well suited for areas with cold winters. Outside, such a building looks like a solid brick wall. The use of cladding rocks eliminates the need for painting or other additional coating.