With the help of the fireplace design, two tasks are solved - saving space in a small room and creating a cozy atmosphere. A corner fireplace stove is appropriate in a private house or small apartment. In the conditions of high-rise buildings, you can choose products without ignition from firewood, and in a country cottage you can make a stone model yourself.

Advantages of Corner Fireplaces

Compared to frontal heat sources, fireplace structures have several advantages:

- Compact dimensions, due to which a small room is not overloaded with objects.

- High-quality heating of adjacent rooms.

- High efficiency - the corner stove reflects heat fluxes from the wall.

- Uniform distribution of heat, since it takes an angle.

- Effectiveness - the fireplace fits into any interior, creates an atmosphere of calm comfort.

- The possibility of organizing a place for a family or romantic vacation, when a lively, soothing fire burns in the hearth.

- Saving materials when building a stone model in the corner compared to island or wall.

- The simplicity of self-creation of a false model.

- The simplicity of ordering. Masonry in the presence of a scheme is easily performed by a novice master.

- Functionality. The design heats the room, provides the house with hot water, is equipped with a hob.

Corner models for 1 hour of operation provide high-quality heating of the room from 120 m3.

Types of corner fireplaces

The classic corner fireplace consists of a portal (case), a firebox, an ash pan, a grate, a smoke exhaust system. Today there are several varieties of heating facilities.

Electric fireplace

Floor and wall models are installed in apartments without permission. The device looks like a standard heater with imitation of flame and ember. An electric corner fireplace is inexpensive and easy to operate.

Fireplace stoves

They support long burning, work on solid fuel. The facade is semicircular, which provides an extended view of the fire. At the time of combustion, heat is reflected from the walls and evenly distributed throughout the room. The following brands are included in the user rating of fireplace stoves:

- Teplodar working on wood. The difference of the structure is compact dimensions, efficiency of 95%. Suitable for a bath, combined with steam generators;

- Bavaria with the upper exit of the smoke channels. A slightly elongated device has a capacity of 9-12 kW and is designed for a room volume of up to 180 cubic meters. A heat-resistant tile lining creates a decorative look, and functionality - a quality hob;

- Eurokom supporting long burning. Polish cast-iron apparatus is equipped with a hob;

- Godin with a futuristic or classic design. French products are available in cast iron and steel casing with tiled lining. Thanks to the secondary afterburning system, the living room, the kitchen or the entire dwelling are warmed up qualitatively;

- Neva from a Russian manufacturer. Firewood is used as fuel. The cast-iron stove has small dimensions (0.87x0.64 m), but it will warm the house up to 60 m2 with high quality.

All fireplace stoves are suitable for installation in country cottages, at dachas, in the private sector.

Biofireplaces

They work on alcohol fuel, therefore they require compliance with the operating rules. The ignition mixture is only poured into a special compartment, and then ignited.Biofireplace is economical - you need to refuel only 1 time in 3-7 hours. Manufacturers are offered a modern way of controlling the intensity of combustion - from a smartphone or remote control.

Brick models

Consider the device and features of brick modifications is the example of the model Annushka, designed by E. Doktorov. The structure is mounted at the external or internal wall of the building.

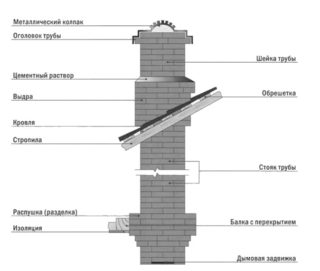

In the classic design, the furnace hole was 0.2 m2, and the width was 2/3 more than the height. For good heat transfer and the absence of smoke, the depth and height of the furnace are correlated as 1: 2 or 2: 3. The chimney is 8-14 times smaller than the furnace. Other features of the author's fireplace include:

- the presence of the foundation is 15-20 cm more than the fireplace space;

- arrangement of shielding made of galvanized iron. Its size is 100x200 cm;

- the protrusion of the upper edge of the screen is 35-36 cm from the furnace and 7-8 cm from the walls;

- the use of ceramic insulators;

- the presence of a heat-resistant layer near the wooden walls - asbestos or fire-resistant drywall is used;

- primary laying of materials dry;

- thermal insulation of the exit point of the chimney to the attic or second floor

- conclusion of the pipe head 50 cm from the roofing.

The brick unit is finished after complete drying.

Gas devices

Buildings are connected only after obtaining permission from specialists. Installation takes a lot of time, but the finished product almost does not emit combustion products, does not require frequent cleaning from soot or soot.

Metal options

To bookmark you will need a wood fuel. Similarly, brick requires the construction of a chimney, but the foundation is made in the form of a layer from below. A factory door made of refractory glass allows you to view the flame.

Choosing a place for installation

Before installing a corner fireplace, brick, gas or electric, you must select the installation location, functionality and type of fuel. The rules allow you to mount the stove in the hall, bedroom, bathhouse, kitchen or street, but there are a few points to consider.

In the corner of the living room at home

The seating option can be decorative, solve heating problems or hot water. During installation, you need to take into account the power of the furnace - the cubic area of the room is divided by 25. That is, for a room of 50 cubic meters, you need a 2 kW model. Steel or cast-iron combustion channels are justified in areas with a cold climate.

In the apartment

An open type of firebox is unacceptable here, as well as a brick construction with a chimney. The best way is a false fireplace in the form of a plasma screen with a picture of a flame. It is mounted on the wall with a latch. The budget option is the design for which cardboard is used.

In the country

A fireplace stove with ventilation, channels for the circulation of air masses is suitable. It is installed only after wall cladding.

For heating a house and hot water

Factory models with a closed firebox provide high-quality heating through the use of a secondary afterburning system. When arranging brick heaters, you can make a circuit for heating water in the form of a water jacket.

DIY fireplace construction

Independent arrangement of the fireplace requires the organization of good traction for the absence of smoke and quick ignition. The heat transfer of the structure should contribute to the rapid and uniform heating of the rooms.

Proportions of corner heaters

Fireplaces are symmetrical and asymmetric in shape. In the first case, the sides are made even, which ensures the universality of the structure. Asymmetric are used for zoning the interior in large rooms. Regardless of the shape, the proportions are selected:

- width and height of the combustion channel - 3: 2;

- depth of the vent with a height of 1: 2

- chimney pipes to the size of the furnace from 1: 8 to 1:15;

- diameter of a round pipe-nozzle from 10 to 15 cm.

When choosing dimensions, the quadrature and volume of the room are taken into account. All data are listed in the table.

| Room | Portal, cm | Firebox, cm | Smoke outlet cross-section, mm | ||||

| Quadrature | Volume | Width | Height | Depth | Neck | Back wall | |

| 12 | 42 | 50 | 45 | 30 | 12 | 30 | 140x140 |

| 16 | 42 | 60 | 50-52 | 32 | 12 | 40 | 140x270 |

| 22 | 60 | 70 | 56-58 | 35 | 12 | 45 | 140x270 |

| 30 | 80 | 80 | 60-65 | 37-38 | 13 | 50 | 270x270 |

| 35 | 100 | 90 | 70 | 40-42 | 13 | 60 | 270x270 |

| 40 | 120 | 100 | 75 | 45 | 14 | 70 | 270x270 |

Size is selected through calculations and compliance with the ratio of parts.

Tools, materials, nuances

Independently build a corner fireplace stove for a house or a summer house from the foundation, then go to the portal, firebox and chimney. At the last stage, finishing with stucco or ceramic tiles is carried out.

For construction work, you need such materials:

- roofing material, polyethylene film, medium-fraction gravel, sand, boards or metal sheets, reinforcement 8-10 mm in diameter - for the manufacture of the foundation;

- red and chamotte solid brick (360-600 pieces), cement, sand and clay (1: 1: 3), metal corners 50x50 or 60x60, plywood, wooden selections, 5 m long pipe, finished valve, asbestos for the furnace;

- stone cladding, ceramic tiles, textured plaster - for decoration.

In the process of building a fireplace you will also need:

- level for checking horizontal seams;

- tape measure or ruler;

- trowel for using the solution and removing its excess;

- rubber mallet;

- diamond / corundum wheel grinder;

- a pick for breaking bricks;

- buckets or other containers;

- spatula and plumb;

- rule - evens the screed;

- angle for checking the perpendicularity of the seam;

- shredding and shovel.

All tools should be at hand so as not to be distracted by searches.

Foundation construction

The foundation is equipped with a protrusion from the fireplace base of 8-10 cm. Before starting the excavation, a foundation pit is excavated with a depth of 50-70 cm in the form of a future building. Then they work like this:

- Tamping the bottom of the pit, filling it with 10-12 cm of sand and subsequent tamping.

- Laying crushed stone on top of sand to a thickness of 10-12 cm and tamping.

- Installation of reinforcing mesh or rods with a further bundle of wire.

- Installation near the walls of asbestos strips to protect the surface from overheating.

- Production of formwork. For a round base, you need a metal sheet of 1-2 mm thick. Under a direct stove, boards fastened with nails are suitable. A plastic film is laid on top of them.

- The manufacture of the solution. The first layer of concrete is poured from a gravel-sand mixture (3 parts) and cement (1 part) to a thickness of 10-15 cm.

- Filling the second layer of the solution based on 3 parts of sand and 1 part of cement.

- Waiting for concrete to set and daily wetting of the surface with water.

The concrete composition fully gains strength in 4 weeks.

Arrangement of the walls of the fireplace

The fireplace wall should not be exposed to fire, therefore, without fail make a heat shield. For him you will need:

- Heat-reflecting foil material fixed with self-tapping screws. The cover should protrude slightly beyond the mantelpiece.

- Ceramic tile. The layout allows you to protect the building from fire and provide room decor.

Consider the thermal protection of the walls at the design stage.

Chimney construction

The correct selection of the diameter of the chimney ducts will provide good traction and high-quality removal of combustion products. The optimal parameters of the chimney cross section are 1:10 of the furnace opening. The standard pipe must be at least 5 m high.

Fireplace Masonry Walkthrough

The instruction for the self-construction of the fireplace provides for a preliminary soaking of bricks in water for 4 weeks. To adjust the size, make dry ordering and docking of each row. Elements can be numbered. When building a stove with your own hands, several schemes are allowed.

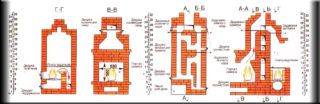

Bykov Order

A simple scheme is suitable for the construction of a small heater for a room from 30 m2. The specificity of Bykov’s technology is the presence of a factory grate 25x25 cm (width 3-5 cm, thickness 5 mm). When laying 1-2 rows, a triangle of 14 bricks is formed, some of them need to be cut. From 4 rows they begin to assemble the firebox using fireclay bricks, and work in stages:

- In the 5th row an ash pan is mounted. Metal strips are laid on the side walls.

- On the 6th row, the grate is laid out.

- From 7 to 12, a fireplace portal is built.

- In the 13th row, metal corners 60x5x0.5 cm are attached and installed.

- When performing the 14-15th row, a “mirror” is made that collects and retains heat. The wall has an angle of inclination of 20 degrees.

- On the 16th row, the tooth is removed, coated with clay mortar for a smooth surface and ease of use.

- From the 17th to the 19th row, a bend of the tooth is created in the form of hewn walls.

- From the 20th to the 22nd row, the height of the chimney of 14x27 cm is laid out and a smoke damper is installed.

- From the 25th row, a chimney is made with an internal channel size of 14x27 cm.

After installation, the metal pipe is closed by a casing.

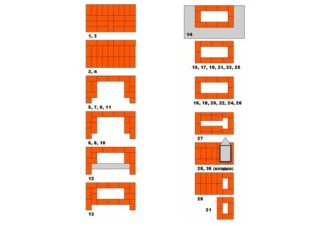

Simple ordering

A simple arrangement allows you to create a square fireplace. When laying materials on an even layer of cement, you need to follow a step-by-step algorithm:

- Form the 1st row in the form of a square of 25 bricks.

- Make the base of the woodcutter, fixing it additionally with a metal 60-cm corner 5x5 cm.

- Lay a metal sheet with sides 40x60 cm and a thickness of 2-4 mm.

- Fully lay in the 4-row layer of brick.

- Collect 5 row of fireclay bricks.

- To make the walls of the furnace of red brick when laying 6-8 rows.

- Put the bricks at an angle of 7-9 rows, forming a tooth.

- Assemble the back wall of the structure in rows 10–11.

- Cover the wall 12-side by using several metal corners 5x5 cm. The length of each element is 60 cm.

- Perform standard laying of 14 rows.

- Block the tooth in the 15th row and form its transition into the chimney duct.

- Make a shelf by slightly moving the outer part of the tooth in the 16-17 row.

- To the 20th row, gradually narrow the smoke exhaust route.

- To make in the 24th row the beginning of the red brick chimney.

- Lay the base of the chimney from the 25th to 29th row.

The smoke damper is placed in the 27th row.

Cladding

Externally, the brick fireplace design looks inconspicuous. To give the building a beautiful view, you can:

- Plaster the surface. The stucco mortar is applied after 14 days - from wet bricks it can crack after drying. To paint the plaster layer is allowed fire-resistant paints.

- Run the lining. Artificial or natural stone looks beautiful. The ability of the material to tolerate temperature fluctuations and to accumulate heat will provide a comfortable microclimate. To create a picture, you should be inspired by a beautiful photo.

- Fix GKL. Plasterboard sheets are fixed on a metal frame, which is welded to the furnace. The finish is varnished and easy to wash or dust.

- Lay out tiles. Using heat-resistant tiles, it is easy to create a beautiful motif or stay on a laconic monophonic cladding.

To get a beautiful picture, make an initial layout of the facing materials on the floor.

Corner models of the fireplace combine the possibilities of an interior object, heating the room and creating a cozy atmosphere. Understanding the principle of ordering, knowledge of the technology of work, the design can be folded by yourself. In the apartment, stay on false models or devices with the effect of a live flame.