When building a bath, it is necessary to organize thermal insulation. Costly heat must be kept inside, and not heat the street. You can insulate a wooden bath from the inside with your own hands. For this, a number of thermal insulators are used. Unlike a residential building, there are some nuances associated with increased humidity and temperature conditions of the room. They need to be considered when choosing a quality insulation.

Technical characteristics of heaters for a wooden bath

The bathhouse is a place with constant contrasting temperature changes, high humidity. In such conditions, finishing materials and structural elements from synthetics are heated intensively and emit harmful substances. Contact with them is fraught with burns.

In order for the bathhouse to become a place of strengthening health, and not its loss, materials are selected for specific operating conditions. The domestic product market offers a wide selection for thermal insulation of a double room. It should have the following characteristics:

- low thermal conductivity;

- resistance to wet environment;

- heat resistance;

- naturalness of materials;

- environmental friendliness.

Felling is collected from cedar, pine, larch. Lining is carried out by lining of pine, aspen, cedar, linden. The insulation for the bath should prevent the formation of mold, keep its original shape, have a low rate of moisture absorption. At the same time, do not have a harmful effect on other structural elements. The bathhouse has been built for decades, therefore, the insulation should serve the entire term of operation.

Water-repellent properties are important for use in the washing department, steam room, sauna.

Thermal insulation is also necessary for the furnace. Materials for use near the stove and chimney must have heat resistance, absolute fire safety, not lose properties from cycle to cycle of the furnace.

Thermal insulation of the outer walls is carried out if the thickness of the timber is insufficient to effectively retain heat:

- perform the crate with the help of a bar or metal guides in the vertical and horizontal direction;

- Mount thermal protection from expanded polystyrene or mineral wool;

- arrange moisture and wind protection;

- equip a counter grill for ventilation of the facade - a distance of at least 2-3 cm should remain between the protective film and the finish;

- perform the finish.

Such insulation will significantly reduce heat loss and is suitable for designing baths made of bricks and blocks. Also, thanks to an additional layer, the building is protected from precipitation, ultraviolet radiation, which significantly extends its life.

Synthetic insulation

The best applicants of modern insulation are synthetic. Natural heat and moisture insulating materials are inferior to them in parameters and are more expensive. The correct use of synthetic materials allows the frame to remain a “thermos” and not to let out heat.

Expanded polystyrene

Expanded polystyrene and polystyrene are the best in terms of price and quality. Lightness and low cost of the material allow the use of the material in the decoration. It is easily molded, cut, installed, attached to any surface with glue, nails and other fasteners, does not absorb moisture.However, there are several restrictions that prevent the widespread use in the insulation of baths:

- high temperature deformation;

- the release of phenol when heated;

- flammability.

All the disadvantages associated with the use in heated rooms. The material can be used for finishing dressing rooms or exterior walls. The joints between the sheets are glued with foam or special silicone.

Mineral wool

Widely used in the construction of mineral wool. This is a universal insulation for a bath - low price, fire safety, biological resistance. Given the lightness of the material, mounting is very simple. It must be borne in mind that it loses its heat-insulating properties when wet. Therefore, the use of mineral wool for the bath should be combined with steam waterproofing. Such insulation is classic for a bath, dressing room, washing inside and out. It is not suitable only for the steam room.

Glass wool

The insulation is similar to mineral wool, only made of molten glass. Available in the form of plates and rolls. Immune to temperature changes. Over time and during installation, the glass melt crumbles, so the heat insulator is not suitable for sheathing the interior without some kind of separating layer. It is widely used in the insulation of the walls of the bath inside the frame along with mineral wool.

Glass wool when used even with vapor-tight film is not suitable for covering the ceiling. Wet material instantly loses its thermal insulation property and can damage ceiling beams.

Basalt fiber

Basalt insulation is considered the safest. The material is made of rocks. Therefore, it withstands high temperatures, does not burn, does not emit harmful substances, is resistant to moisture.

A service life of 30 years, excellent sound insulation, simple installation put this material a priority over other heat insulators. Temperature fluctuations and high humidity do not violate thermal insulation. She is not interested in rodents, insects do not start.

The material has not many drawbacks - a high price and high weight. Suitable for insulating horizontal surfaces - floor and ceiling.

Waterproofing for insulation

Popular materials are bitumen mastic, euroroofing material, glass hydrosol, thick polyethylene with a density of 140 microns.

Waterproofing with the help of films has proven itself in construction. This material is a combination of low and high pressure polyethylene with oxidizing agents. Such material is very thin - 0.3-3 mm. Thick membranes are sometimes used with greater reliability but reduced flexibility.

Due to its advantages, such waterproofing is excellent for cinder block and gas block baths.

A typical representative of waterproofing films is Ondutis material in several modifications.

Steam Bath Insulators

The vapor barrier of the room should not be equipped with synthetic materials. Under the influence of hot steam, they emit harmful chemicals. Optimal materials are:

- kraft paper;

- aluminium foil;

- foams laminated foams;

- glassine.

The ideal option is aluminum foil. This material does not absorb moisture, is fireproof, and durable. The foil reflects infrared waves, which accelerates the heating of the room.

Ruberoid and glassine are not used inside the steam room. When heated, they emit harmful substances. Occasionally, glassine is used as insulation.

Work sequence

The first stage of thermal insulation occurs during the construction of walls.When assembling the log house, a jute gasket is placed between the crowns. Sometimes it is replaced with moss, flax or other fibrous material. The process is completed in a few months, filling the falling ends with caulk. For beauty, high-quality sealants are used that do not crack in frost and during wall deformation. Environmental friendliness is important for the bath, therefore, natural materials of intervening gaskets are a priority.

Ceiling

To protect against the harmful effects of hot steam and condensate, the rafters are coated with a mixture of sawdust with clay or modern technological mixtures. To maintain a constant temperature, high-quality thermal insulation of the ceiling of the bath is required. The walls and ceiling of the room are insulated after shrinkage from the inside and outside. Step-by-step procedure for ceiling insulation:

- With a roll of paper, the ceiling of the room is lapped. It is strengthened by adhesive tape or a construction stapler.

- Beams with excess thickness of the insulation are attached across the ceiling. Basalt wool or slag fiber is used as a steam room heat insulator. For insulation of the dressing room and other rooms, expanded clay, a mixture of sawdust and clay are allowed.

- Insulation mats are inserted completely between the bars.

- As a vapor barrier, a foil with sizing of the seams with vapor barrier tape is placed on top.

- On top of the foil, a lath for fastening with a lining is attached.

- When using the ceiling as the floor of the upper room, the insulation scheme looks different. 3 cm cement screed is laid on top of the insulation. Wooden flooring is laid on it.

Around the pipe of the furnace passing through the attic, a rafter box is mounted to provide a space of 20 cm between the pipe and the heater. Inside, it is laid with a non-combustible heat insulator - basalt or glass wool.

Walls

Insulation of the steam room from the inside in a wooden bath depends on the material of the building. A crate of bars is packed on a beam. The size of the bar should be greater than the thickness of the insulation by 2-3 mm. Between the bars, a heat-insulating material is laid by surprise. A vapor barrier is applied on top with a shift. The distance between the insulation and vapor barrier should not exceed 3 cm. A gap is left to ventilate the finish and prevent condensation. Corners, joints, pipes and other problem areas are glued with insulating tape. This will protect against moisture penetration into problem areas.

Work is carried out from top to bottom. Sometimes magnesite boards and gypsum fiber are used as thermal insulation. As a vapor barrier, it is permissible to use a foil-resistant parotherm that is resistant to high temperatures.

On top of the resulting layer, a low density wood trim is sewn. The best material is linden and aspen.

Walls of panel and frame buildings are insulated with only light materials. Before laying, they are treated with milk of lime to increase fire resistance. After processing, the material dries well.

Floor

Insulation of the floor occurs if it is made of concrete. To do this, the soil is leveled, a sand cushion is being added. An expanded clay layer is laid on the pillow. Expanded clay is filled in with a base floor.

The second method is suitable for the device in the steam room:

- a 15 cm layer of mineral wool is laid on the base floor;

- superimposed euroroofing material with approach to the baseboard;

- lags are treated with an antiseptic solution;

- laying of the rough floor;

- the finishing floor from the tongue-and-groove board is covered on top.

Additional insulation of the windows of the bath

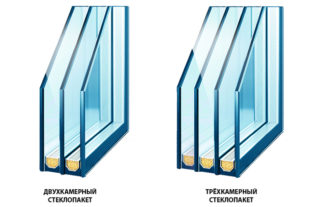

Windows are the main enemy of the steam room. They are the main source of heat leakage and are subject to additional insulation. They are built in the lower part of the room in small sizes.For heat preservation, triple glazed windows are required, provided that the slots are completely sealed with insulators and a tight insert in the opening. The main cracks are located around the perimeter and under the windowsill.

Window tightness conditions:

- cut glass strictly to fit the frame;

- during installation use putties on top of the glass and directly on it;

- reinforcing nails are completely oiled;

- the lower the glass, the less heat loss.

Double-glazed windows give good parameters when warming, but they are expensive. Doors to the bathhouse are also usually made low to prevent heat leaks. The door frame is insulated similarly to the window.