Facade warming of the house allows you to reduce heat loss, reduce heating and cooling costs, and helps to create a comfortable indoor climate. This event is held at any stage of the operation of the building, both during its construction and several years after the end of the shrinkage process. The procedure of insulation and decoration of the facade is not particularly difficult, it can be done with your own hands, saving money on the services of a team of specialists. To ensure that the final result of the work meets the intended criteria, you should familiarize yourself with the assortment of heaters on the market and the technology for applying them. The choice of foam is the best solution for thermal insulation of the facade of the house from the outside. The material has a number of positive characteristics, which are appreciated by private and professional developers.

Characteristics of expanded polystyrene

In retail outlets you can find polystyrene foam extrusion and type. In the first case, the plates consist of closed porous granules. The second type is a foamed mass, frozen after passing through a mold.

Polyfoam has the following specifications:

- density - 25-35 kg / m³;

- compressive strength - 0.18 MPa;

- bending strength - 0.25 MPa;

- water absorption —0.4% of the volume;

- fire resistance category - G4;

- thermal conductivity coefficient - 0.030W / (m × ° s);

- sound insulation - 41 db;

- dimensions - 100 × 100 cm, 60 × 120 cm;

- thickness - 20, 50, 100, 150, 200 mm.

Polyfoam is versatile. It is used for insulation of garages, private and apartment buildings made of bricks, reinforced concrete panels and gas silicate blocks.

Advantages of insulating facades with polystyrene foam

Insulation of the facade of the apartment from the outside with polystyrene foam allows you to achieve a good economic effect with small financial investments.

Insulation of the facade of the apartment from the outside with polystyrene foam allows you to achieve a good economic effect with small financial investments.

The material has the following advantages:

- Low specific gravity. Finishing does not exert additional load on the supporting structures of the building.

- Water resistant. Plates reliably protect the walls from moisture, which could cause their premature destruction and adversely affect the appearance.

- Long term of operation. Depending on the type of expanded polystyrene, it is 50-80 years.

- Low thermal conductivity. For a 10 cm thick slab, the degree of insulation is equivalent to one meter brickwork.

- Moisture resistance. The polymer practically does not absorb water. Even while in a humid environment, it retains its characteristics.

- Biological inertness. Fungus and mold do not start on the surface and in the array of plates.

- Frost resistance. The material is designed for 50 freeze-thaw cycles.

- Environmental Safety. The insulation does not emit substances harmful to people, animals and plants into the environment.

- Easy installation. Plates are lightweight, easy to cut, and saw with ordinary household tools.

- Affordable cost. The price of mineral wool for facade insulation will be an order of magnitude higher, with the same insulation effect.

When deciding in favor of polystyrene, its negative aspects should be taken into account. Material is destroyed by ultraviolet radiation. In it, insects, birds and rodents like to make nests.

The choice of expanded polystyrene for the facade

Choosing a heater for a ventilated facade, you should focus on a number of factors, not giving priority to the price side. The construction is done for decades, the use of low-quality material can save its service life at times.

Recommendations for choosing a heater:

- Selected edges around the edges. This option facilitates and speeds up installation. There are no cracks and cold bridges on the surface.

- Verified manufacturer. The leader in this direction is the products of the Technonikol company. Plates of its production are painted in orange, which makes it easy to detect fake.

- Material type. Plain white polystyrene is well suited for insulating smooth concrete walls over a large area. It is chosen for finishing buildings whose facade does not conduct air. Extruded polystyrene foam differs in vapor permeability, it can be used to insulate buildings made of wood and porous blocks.

- Strength. If you plan to make a facade of clinker tiles with insulation, you need to choose a material with maximum compression ratios.

- Thickness. It determines how well the building will be isolated from high and low temperatures. For regions with a temperate climate, the best option would be 5 cm. In regions where the thermometer column rises or falls to the level of 40 degrees, it is better to insulate the facade of the house with polystyrene foam 10 cm thick.

When purchasing goods, you should pay attention to the integrity of the packaging, the presence of markings and a certificate of quality.

Used equipment and materials

When planning external insulation, you should initially determine the method of getting to the height. If you have the appropriate skills, you can use climbing equipment. It is easier to rent scaffolding, which is more convenient and safer to work on.

To insulate the facade with foam with your own hands, you will need such tools and materials:

- puncher, screwdriver;

- roulette;

- hammer;

- hacksaw for metal;

- level, rule;

- scissors, clerical knife with additional blades;

- serrated and leveling spatula;

- paint brush;

- primer for concrete, plaster, frost-resistant adhesive, acrylic paint;

- siding (if provided by the project);

- steel profile;

- mushroom-shaped dowels, metal screws;

- plastic corners with a grid;

- polyurethane foam;

- mineral wool.

Decorative insulation of facades during processing emits a large amount of dust. Foam must be handled with goggles, gloves and a gauze bandage. It is necessary to install a fence along the wall or pull the signal tape.

Insulation technology

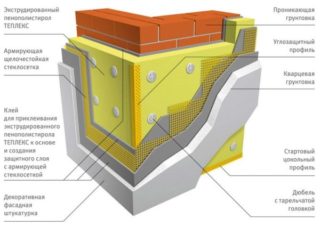

Properly organized work is a step-by-step process of sequentially performed actions corresponding to the building insulation technology. With the external version of the foam insulation, it is necessary to consider its protection against ultraviolet radiation. Mineral wool for a wet facade is used in areas where the destruction of bearing surfaces is possible. In multi-storey buildings, these are joints between vertical reinforced concrete panels.

You should start with the preparation of the project. Measurements are being taken, the results of which are transferred to paper. Then, an arrangement of the frame and plates is made, calculation and purchase of building materials is done.

The next phase is the preparatory work. They are performed in the following sequence:

- remove nails, dowels, wiring, plates, lighting;

- knock down fragments that exfoliate or do not hold firmly to the surface;

- grind protruding fragments;

- close up holes, cracks, indentations.

The result of the work is checked by level or rule.

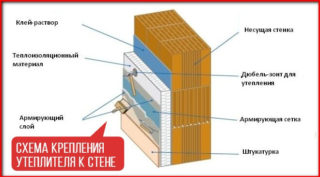

After the cement mortar has dried, which has been leveled, the wall must be double-coated with a deep penetration primer.This procedure is needed to strengthen the base and increase its adhesion to the adhesive. Then steel suspensions are installed. With their help, a spatial diagram is drawn up, due to which the plates are aligned vertically, horizontally, as well as the position relative to the wall. If provided by the project, suspensions are used as the basis for the installation of siding.

The installation of expanded polystyrene begins with the installation of a starting profile on the bottom of the future masonry. The profile is the basis for the first row of foam, and also protects it from insects and rodents.

When attaching plates, you must adhere to such rules:

When attaching plates, you must adhere to such rules:

- You need to start laying from the corner to dock the products in the lock;

- knead glue in an amount that can be put into action until it thickens;

- apply the mixture pointwise or over the entire surface with a notched trowel;

- each subsequent row is stacked with an offset to the floor of the figure;

- it is allowed to seal the gaps only with mounting foam, and not with glue, so that cold bridges do not form.

After laying out the top row, you should perform the following manipulations:

- Drill 5 holes in each plate. Drive the plate-shaped dowels into them so that their caps are recessed 1 mm in the foam.

- Seal with cement mortar the recesses remaining from the dowels.

- Carry out reinforcement. First you need to strengthen the corner with a plastic profile, and then stick a plastic mesh on the insulation. Each subsequent strip of the mesh should be superimposed on the previous minimum of 10 cm.

In conclusion, surface finishing is carried out. The best option is to use a polymer-based facade plaster. It is applied with a layer up to 3 mm thick with a wide spatula. After hardening, the plaster is sanded and polished. Then it must be strengthened with a liquid primer to give strength and preparation for the next phase of finishing. The last stage of the facade insulation is its coloring. You should choose paints that are resistant to temperature extremes and high humidity. As an option - you can lay the wall with ceramic or clinker tiles.