Is there an alternative to traditional wood? Despite its availability and relatively low cost, the heat transfer of wood leaves much to be desired. To improve this parameter, briquettes for heating were developed: reviews, production, peat, coal, wood. How relevant is their use as the main energy carrier?

Features of fuel briquettes

In fact, coal or wood briquettes for heating are compressed combustible material that has passed the pre-treatment stage. To improve energy quality, they may contain various additives.

Reading reviews of briquettes for heating, we can conclude that they are much more efficient than traditional types of fuel. This quality is formed in the process of manufacturing Eurodra. Using a special technology for processing the starting material, an energy carrier is obtained which is characterized by the following qualities:

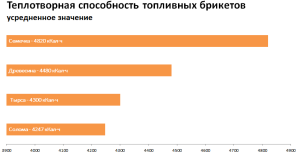

- High heat transfer. On average, coal briquettes for heating in the amount of 1 kg are 1.8 kg in energy value. simple firewood;

- Low humidity, which does not exceed 10%. As a result, the specific heat transfer increases;

- Convenient storage. The round, cylindrical or cubic shape of the eurodrods helps to optimize their storage location;

- Uniform heat transfer. This is very important for the stable operation of the heating system with a solid fuel boiler.

However, disadvantages must also be considered. So, briquettes for heating RUF are sensitive to moisture. Suitable conditions and facilities are required for their storage. In addition, the cost of briquettes is higher than that of firewood. Given the energy value, the difference will be literally 5-7 kopecks. at 1 watts.

Coal briquettes for heating should not be fully packed in airtight film. Ventilation gaps are required for air circulation.

The specifics of the production of briquettes for heating

The peculiarity of the manufacture of Eurodroves is the use of waste from the woodworking industry, agriculture and coal mining. The production of briquettes for heating can be organized on the basis of any of the above enterprises.

For manufacturing, it is necessary to choose the right source material. The proper production of briquettes for heating begins with the preparatory phase. Depending on the available raw material base, several types of materials are distinguished:

- Agricultural waste - husk of seeds, straw. The first has the greatest energy capacity. However, it is also characterized by high purchase costs;

- Sawdust. The most suitable option, since it is from them most often that briquettes are made for heating with your own hands;

- Peat. It needs a complicated preparatory process, as it initially has high humidity;

- Coal. In fact, they use the so-called coal dust, which is a by-product of mining.

Preparation of the feedstock includes pre-grinding and further drying. This is necessary to reduce humidity, since heating with sawdust briquettes will be beneficial only if the water content is not more than 10% of the total volume. Then fixers and modifiers can be added to the resulting material to increase heat transfer.

For full production, in addition to the press (extruder), you will need a mechanism for packing briquettes.

Types of briquettes for heating

In fact, euro-woods differ not only in the raw materials, but also in the way they are processed. The easiest manufacturing method is pressing. For the production of briquettes for heating RUF, a special belt press of the same company RUF is needed. It was from him that the name of the eurodroves of this type went.

The advantage of this process is the speed of manufacture. Pre-prepared raw materials are loaded into the receiving chamber, and then with the help of screws it enters the pressing zone. Those. in fact, the production of briquettes of this type will require a minimum of investment and effort.

However, the final product has a number of features:

- Almost all reviews of peat briquettes for heating indicate their susceptibility to moisture absorption. Therefore, you need to take care of the appropriate storage location;

- Eurodroves made on the original equipment have an imprint on the surface. In most cases, this indicates compliance with manufacturing technology. But it all depends on the quality of the feedstock.

To improve performance, it is best to choose a different production method. Peat briquettes for heating in addition to pressing pass the stage of surface firing. Thus, a moisture-resistant outer shell is formed, which in addition contributes to the improvement of mechanical resistance.

Additionally, a heating zone is provided in the equipment, which is located around the feed press screw. A similar manufacturing technology was called Pini Kay. Its feature is relatively low productivity compared to RUF. However, wood briquettes for heating pine key have a much longer shelf life. In addition, their increased density has a positive effect on heat transfer.

The following qualities are characteristic of this type of eurodrove:

- Convenient form for loading into the furnace chamber of the boiler;

- The ability to burn for a long time.

However, the production process is not always followed. This is especially true of the quality of external firing and the quality of pressing. In most cases, the specific gravity of a coal briquette for heating may vary.

The color of the eurowood depends on the starting material. In peat briquettes for heating, it will be dark brown or black. Made from sawdust on the RUF press, they have a white or light yellow hue.

Material selection

The determining factor in the quality of Eurodroves is the raw materials for manufacturing. Most do-it-yourself briquettes for heating are characterized by low heat dissipation precisely because of improperly selected and prepared material.

The most popular at the present time are the waste from the forest industry - sawdust, shavings, etc.

Wooden briquettes for heating

In the reviews about briquettes for heating, it is the wood models that express the most controversial opinions. This can be explained by the features of the source material of manufacture. Unlike coal briquettes for heating, eurowood from wood waste has one significant drawback - moisture absorption.

This can lead to an artificial increase in mass due to the increased water content. Alas, there are no regulatory documents for the manufacture of Eurodroves. Therefore, manufacturers most often introduce internal standards that may not always meet the expectations of the buyer. If the technology was followed during the production of wood briquettes for heating, then the product must meet the requirements from the table.

| Characteristic | Value |

| Bulk weight, kg / m³ | 125 |

| Briquette density, kg / m³ | 1150 |

| Humidity% | 6-10 |

| Calorific value, MJ / kg | 25 |

| Ash content,% | 0,5-1,3 |

How to distinguish a quality product from a dubious one? The first should have a number of qualities:

- Uniform firing of the surface or the correct form of cubes of RUF;

- No condensation on the surface or streaks from water;

- The uniform shape and size of all briquettes from the same batch.

But besides this, you need to ensure the correct storage location. To do this, it is recommended to use a separate room with normal ventilation and room temperature. When organizing briquette heating from sawdust, fuel is most often stored in an adjacent room.

Best of all, fuel briquettes have proven themselves in long-burning fuel boilers.

Peat and coal briquettes for heating

The use of peat and brown coal for the manufacture of do-it-yourself heating briquettes is due to the large reserves of raw materials. This helps to reduce the cost of production, and as a result - reduce heating costs.

The main problem with peat and coal briquettes is initially high humidity. To solve it, it is necessary to perform the drying procedure in special sealed thermal chambers. However, the high cost will not allow most manufacturing enterprises to include them in the process.

As a result, peat heating briquettes are characterized by slightly worse parameters than similar ones from sawdust.

| Characteristic | Value |

| Bulk weight, kg / m³ | 280-400 |

| Briquette density, kg / m³ | 500-600 |

| Humidity% | 12-18 |

| Calorific value, MJ / kg | 16-18 |

| Ash content,% | 3-5 |

Also, unlike sawdust eurodrakes, ash from peat or coal analogues is practically not used as fertilizer for the soil. In addition, most often they are made by pressing without additional surface firing. This leads to a decrease in the strength and shelf life of coal heating briquettes.

To preserve the thermal conductivity of the fuel briquette and reduce its moisture content, it is recommended that some of them be stored in the boiler room.

Do-it-yourself briquettes

Is it difficult to make wood heating briquettes at home without special equipment? To do this, you need the simplest lever press and mold for Eurodroves.

Sawdust or waste paper can be used as feedstock. Often these components are combined with each other to improve quality. To obtain a homogeneous mass in a peat heating briquette, a binder component is required. It can be water or clay. Then you will need to perform the following manufacturing steps:

- Crushing the feedstock and adding a binder component.

- Form filling, pressing.

- Drying the workpiece.

RUF factory heating briquettes are manufactured using the same technology. The difference lies in pressure and production volumes. At home, to provide fuel for the entire heating period, the manufacturing time can take from 7 to 20 days.

It is recommended to make a form of several cells. This will greatly increase manufacturing speed.

Customer reviews

How objective can reviews of peat heating briquettes be? The snag lies in many external factors that affect the effectiveness of their use. First of all, this concerns the boiler, since the heating efficiency of briquettes from sawdust or other source material depends precisely on its parameters:

- We decided, as an experiment, to heat the boiler with briquettes from sawdust. Heat dissipation was extremely high. However, fuel consumption has also increased. Alas, the draft was too good in our old boiler. Now we use them if you need to quickly melt a house;

- First ordered the cheapest fuel pellets in the form of tablets. They quickly burned out, gave relatively much ash. Then they decided not to save and bought a batch of RUF eurodroves.The differences turned out to be significant - the time of complete combustion increased, the heat transfer increased;

- They approached the issue of heating the house thoroughly - they purchased a boiler for long burning. Peat fuel briquettes were sampled. After long trials and experiments, we found out that it is best to use them together with firewood in a combination of 1/3 (briquettes, firewood).

It is important to remember that all types of fuel briquettes are designed for solid fuel boilers of pyrolysis type or long burning. Their use in conventional will not give the desired effect.

The video shows a home-made installation for the manufacture of fuel briquettes: