Metal-plastic pipes were one of the first to appear as an alternative to replacing traditional steel pipes. They differ in simple installation technology, the ability to make complex highways with many turns, a smooth surface. But what in practice are metal-plastic pipes for heating: reviews, installation, diameters, disadvantages and advantages will help to assess the relevance of their application.

The construction of plastic pipes

Modern metal-plastic pipes for radiators obtained their unique properties through the use of polymeric materials. For their manufacture, cross-linked polyethylene is used. But since it does not have the necessary rigidity, an additional layer of aluminum foil is installed to give the pipes the necessary technical properties.

Manufacturing technology allows you to make different diameters of plastic pipes for heating. For this, the extrusion method is used, the essence of which is to install the outer and inner layer of polyethylene on an aluminum base. A special glue is used as a binder. The final technical characteristics of metal-plastic heating pipes make it possible to operate them even at high-temperature operation of the system. In addition, it should be noted such distinctive qualities of metal-plastic pipes:

- Low thermal conductivity. In fact, the main line will not heat up much, thereby reducing heat losses of heating;

- A smooth surface helps to reduce the hydraulic resistance of the system;

- The small specific gravity makes it possible to carry out the installation of heating from plastic pipes independently;

- Simple installation. However, to connect individual sections of the pipeline, it is necessary to use special mechanical fittings. The quality of maintenance will largely determine the maintenance-free life of the heating.

Why are reviews about metal-plastic heating pipes not always positive? This is due to the large number of low-quality products on the market and neglect of installation technology.

Before purchasing plastic pipes, labeling should be studied. It indicates maximum exposure temperature and pressure limit values.

Special properties

Before considering the disadvantages of heating from plastic pipes - you need to objectively evaluate their negative aspects. They are the result of the use of polymeric materials and aluminum foil as a rigid base. Although they do not corrode, some types of pipes use a polymer that breaks down under direct sunlight.

In addition, it is necessary to take into account the difference in the thermal expansion of polymers and the aluminum shell. With sharp heating, the polyethylene layer will expand much faster than the foil. This will lead to delamination of the structure. Given this factor, the question arises - is it possible to use plastic pipes for heating? Yes, but subject to the following operating conditions:

- Minimizing the manifestation of water hammer and sharp jumps in temperature in heating;

- Concealed installation in those parts of the room where there is a high probability of sunlight falling on the highway;

- No surface tension, use of compensation loops to reduce the likelihood of a break in the system.

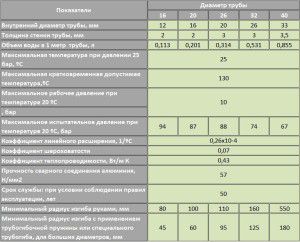

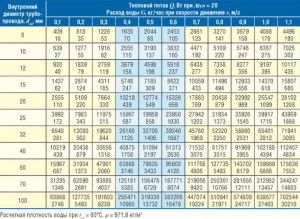

To make a final decision, it is recommended to familiarize yourself with the technical characteristics of metal-plastic heating pipes. To do this, you need to study the table data.

Despite the fact that during the installation of heating from plastic pipes they can be bent - repeated deformation can lead to cracks or chips on the surface. This should also be taken into account during the execution of work.

Like steel, metal-plastic pipes can be destroyed by exposure to negative temperatures due to expansion of the liquid in them. In this case, it is necessary to perform warming of the trunk, as well as the installation of a heating cable.

Installation of plastic pipes

Before purchasing metal-plastic pipes for radiators, you should choose the right diameter. When performing a standard calculation, it should be borne in mind that manufacturers indicate the outer size. Two wall thicknesses must be taken from it in order to obtain the value of the useful section. So, for a 20 mm diameter metal-plastic pipe for heating, the size of the internal cavity will be 16 mm.

Only then can installation of pipelines begin. To do this, you need at least a minimum set of tools - pipe scissors, a spring-pipe bender and a calibrator. The latter is a steel pin with standardized diameters.

Compression and press fittings

The main mounting elements of the system are fittings for metal pipes for heating. They differ in the way they are attached to the nozzles, as well as the material of manufacture. To create a high-quality pipeline, it is recommended to use stainless steel or brass products.

Types of fittings:

- Compression. Fastening takes place by clamping the pipe plane between the fitting and the threaded union nut;

- Press fitting. Installation requires a special crimp device. Despite the high cost compared to compression, press fittings are much more reliable and practical.

Among the disadvantages of heating from metal-plastic pipes, low reliability of mounting of mounting units can be distinguished. Most often this happens when using compression fittings, since for a reliable connection it is necessary to exert sufficient force when tightening the union nut.

To install a reliable highway, you will need not only good metal-plastic pipes for heating, and high-quality press fittings.

Crimping pliers can be rented. But in order to minimize the time of their use - you need to prepare all the other tools and components in advance.

Installation of plastic pipes

In most cases, negative reviews about metal-plastic heating pipes associated with non-compliance with installation rules. Therefore, it is required to study the recommendations of the manufacturers, as well as read the installation instructions.

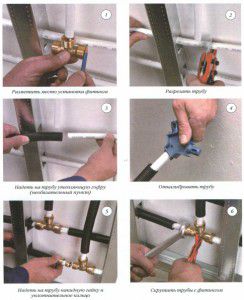

Once it has been decided that metal-plastic pipes can be used for heating systems, an installation diagram is drawn up. To do this, on the plan of the house, the location of the highways, their main nodes and components is drawn. Then, the amount of required materials and components is calculated. Step-by-step installation procedure:

- With the help of scissors, a piece of pipe is cut.

- Using the calibrator, the inlet pipe is aligned for installation in the fitting.

- By installing the press fitting, it is clamped. For this, crimping pliers are used.

For good metal-plastic pipes for heating, a spring bender can be used. However, the minimum bending radius should be observed, depending on the pipe section.

It is recommended to purchase crimp fittings for metal pipes for the heating system from the same manufacturer that manufactures the pipes.

Manufacturers of metal-plastic pipes and their prices

One of the determining factors in the use of high-quality metal-plastic pipes for radiators is their manufacturer. There are currently several leading companies whose products meet quality standards. In addition, they provide clear installation instructions, the choice of diameters of metal-plastic pipes of the heating system, as well as recommendations for their maintenance.

Henco

This Belgian brand is a leading manufacturer of plastic pipes for heating systems. A distinctive feature of their products is considered a manufacturing method. For this, the aluminum tube is formed by the method of spot laser welding. Then a layer of high density polyethylene is applied to the inner and outer surface. The result is a product with good technical characteristics inherent to high-quality metal-plastic heating pipes.

Pex

Thanks to the latest developments by Pex specialists, it became possible to install metal-plastic pipes in a heating system with high temperatures and pressures. Using high-density low-density polyethylene, three-dimensional bonds are created. This gives a guarantee of the absence of delamination, and also increases the threshold pressure (up to 20 atm.) And temperature (up to +95).

In addition, a detailed manufacturing scheme does not allow oxygen to enter the coolant. The company also manufactures fittings for plastic pipes in heating systems.

| Name | price, rub. |

| Henco pipe 16 mm | 30 |

| Henco pipe, 20 mm | 38 |

| Pex pipe, 16 mm | 108 |

| Pex pipe, 20 mm | 189 |

| Compression fitting, 20 mm | 82 |

| Crimp fitting, 20 mm | 172 |

It is not recommended to use metal-plastic pipes for central heating. The reason - possible water hammer and sudden temperature changes.

Reviews

- I heard a lot about the shortcomings of heating from plastic pipes. However, at my own peril and risk, I decided to install them in a country house. He approached the matter thoroughly - he chose high-quality pipes and fittings. After a short training, I managed to mount everything myself. The system works for 2 years without complaints and breakdowns;

- At one time, I heard about the good quality of plastic pipes. Reviews of neighbors and friends influenced my choice. However, I encountered one problem - for flush mounting, it is necessary to install revision hatches at the pipe joints. This slightly spoiled the appearance of hidden heating;

- Having installed plastic pipes in his apartment, he regretted it. “Thank you” to the management company - the constant changes in pressure and temperature led to delamination of the pipes. I had to replace all the mains.

The maintainability of plastic pipes should also be considered. The replacement time for a specific site can be measured in minutes, if the house has a minimal set of tools.

Video instructions for installing plastic pipes: