It is possible to undertake the installation of a heating boiler in a private house only if there is a good theoretical background and practical skills in handling tools and equipment. Even if a decision is made to turn to the services of specialists, knowledge of the issue will help to choose the right devices and the optimal place for their placement, to monitor the activities of hired workers. Properly completed installation of the boiler at home is the basis of reliability and ease of use of an autonomous heating system.

Types of heating boilers

The choice of a heating device is determined by the range of fuel, its availability and cost. The installation of heating boilers should be planned with the expectation that it is not difficult to buy fuel for it, conveniently and safely store it. At the same time, expensive, high-quality and economical equipment should be purchased. The larger the initial investments, the faster they will pay off.

Based on these criteria, a decision should be made in favor of products of the following types:

- Gas. To date, these are the most popular devices that are installed in private homes and city apartments. Due to the presence of its own fields and a developed network of transportation of natural fuel, it has an affordable cost and is supplied to almost all regions of the country. A wide range of products is on sale; the boiler can be installed both in a separate boiler room and in a residential building, provided that the product is equipped with a closed combustion chamber. Installing a gas boiler makes sense only in those buildings where the central highway passes.

- Solid fuel. Products work on coal, wood and briquettes. They are divided into standard open-hearth furnaces and equipped with a long-burning system with an automatic fuel supply system. Universal designs are designed for the processing of municipal solid waste, plastic and automotive rubber. The advantage of such stoves in their independence from external sources of energy, the minus is the need for constant addition of fuel to maintain combustion.

- Electric. Such boilers are compact and light in weight, since they do not have a combustion chamber. In the presence of a backup energy source, the products can be called relatively autonomous. Installation of an electric boiler does not require coordination with management companies. The design is absolutely safe in all respects, including the absence of harmful emissions into the atmosphere. The software allows you to set the time on and off the device, heating and cooling radiators. Installation of electric boilers is not difficult, it can be done with your own hands. The lack of equipment is only in the high cost of energy.

- Fuel oil. Units process diesel fuel, fuel oil, and used oils of all types into heat. Since these types of fuel are available almost everywhere and always, supply problems are rare. Boilers are characterized by good performance and heat dissipation. Cons in the high cost of fuel, difficulties in its storage and high toxicity of combustion products. In addition, stoves need regular shutdown and soot cleaning.

- Solid fuel

- Electric

- Liquid fuel

Each type of heating boiler has its own advantages and disadvantages.Choosing a product, one should carefully evaluate their advantages and anticipate possible difficulties during installation of a heating boiler and its operation.

Types of heater design

Modern water heaters are produced in various designs, due to their size, power and location.

There are such types of heating boilers:

- Wall mounted. Products are lightweight and compact, which makes it possible to hang them on the wall. This category includes gas and electrical devices whose enclosures do not heat up during operation. The advantage of this design is that it is not difficult for her to find a place even in cramped rooms, such as a kitchen, a bathroom and a small basement. Under the appliances, dirt does not accumulate, the room is easy to clean. In addition, there is no risk of flooding of the device during breakthroughs of water lines or flooding of underground structures with groundwater. The wall-mounted boiler can only be mounted on a wall made of durable and reliable material.

- Floor standing. This category includes furnaces with a large weight, size, operating on all types of fuel. If the installation of floor boilers with a heating case is carried out, then a protective screen is installed. A solid base is set up in a wooden house to prevent a change in the position of the device in space. If it is decided to install an oven with an open combustion chamber, then the room must be equipped with an efficient chimney and forced ventilation.

- Floor boilers need a separate room with ventilation

- The wall-mounted boilers do not heat up, therefore it is safe to operate them

Priority should not be given to aesthetics and convenience, but to safety and practicality. Before you make the installation of home heating boilers with your own hands, you need to objectively assess your capabilities and the consequences of errors.

Steps for installing and starting boilers

The installation of the boiler is a procedure consisting of several successive steps. Each of them needs to be given due attention, since the final result directly depends on the quality of each phase of the process.

Arrangement of an autonomous heating system should be carried out in the following order:

- Learning the task. You need to start by determining the required heater power. The basis is a coefficient of 10 m² of the total area of the building. It is 0.9 for the southern regions, 1.2 for the middle lane, 1.5 for the moderate and 2 for the northern. To the obtained value is added 20% to increase power to a maximum in extreme frost.

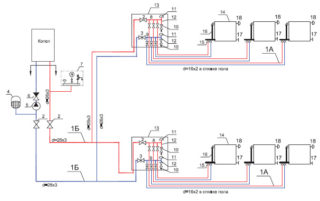

- Design. For furnaces on electricity, solid and liquid fuels, household cylinders with propane, the project can be done independently. For a gas boiler from the central supply, the project is done in strict accordance with SNiP 31-02-2001 and SNiP 42-01-2002. The paper displays the oven, chimney, piping, radiators, bypass, ventilation system, electrical and gas wiring. The compiled documentation must be checked and approved by the gas management company. Start work only after obtaining permission and approved specifications.

- Equipment selection. It is necessary to determine the type of boiler, a set of protective and control options. The more powerful and complex the device, the more expensive, more reliable and more economical it is. When choosing a double-circuit boiler with an internal centrifugal pump, problems with hot water for domestic needs and circulation of the coolant through the system will be solved. For more correct operation of heating, a heat accumulator and a membrane expansion tank will be required.

- Installation. Arrangement of autonomous heating is carried out in accordance with the technical conditions or independently prepared plan.First, a boiler, end devices and consumers are installed, then they are connected by pipes. The next step is to install a chimney and ventilation. Lastly, electricity and gas are supplied, if it is planned to connect the house to common communications.

- Launch. Before the trial run, hydrodynamic tests of the assembled structure are carried out. The purpose of this procedure is to identify circuit and instrument defects. The system is sealed, after which it is filled with hot coolant under a pressure 2 times the nominal. When there are no leaks, the boiler is started in operating mode.

If the boiler room is connected to the central highway, the devices are sealed, and the certificate of putting the boiler into operation is presented to the owner. It should be prepared for the fact that the inspectors will visit the house every month in order to verify compliance with the rules for the use of equipment, its inspection and adjustment. In cases with electric, solid fuel and liquid fuel furnaces, there will be no such inconvenience, but control, preventive and repair measures will have to be carried out independently.

Basic work and installation rules for boilers in a private house

If the power of the device exceeds 30 kW, it must be installed in a separate room. For a small pendant, such restrictions do not exist. The basement can only be used if there is no access by unauthorized persons.

Regardless of the installation location of the furnace, the entrance door to the room should not be less than 0.8 m and the distance to the heater should be more than 1 m. Before installation, the base for the boiler must be leveled and strengthened. This will contribute to a minimum level of vibration, maintaining the integrity of screw joints and extending the life of the structure.

Since there is always a risk of current breaking through the case, it is necessary to ground and use three-terminal sockets for connecting devices. If the case of the device heats up, then the objects around it are finished with non-combustible materials. It can be tile, metal, ceramic paint or facade plaster. Sheet metal or asbestos-cement plate is laid on a wooden floor.

The chimney is laid depending on the location of the boiler. The design may be external or internal. In the first case, the integrity of the floors is maintained, but the traction is reduced. In the second embodiment, there are no problems with traction, but it is necessary to perform labor-intensive work to bring the pipe to the roof and isolate the holes. In order to save forces and money, it is not allowed to combine the chimney and ventilation into a common channel. This is fraught with the ingress of combustion products into residential premises. When laying the chimney, do not make turns at an angle of 90 degrees, as this negatively affects the efficiency of gas removal. The creation of more than 3 turns throughout the pipe is not allowed.

The minimum height of the chimney above the level of a flat roof or ridge of a gable roof should be 50 cm. The pipe section is closed with a grate and a hood to protect it from falling into the channel of debris, rainfall, small birds and animals.

It is imperative to install supply and exhaust ventilation. The air intake should be at the bottom of the wall as far as possible from the stove. For guaranteed smoke removal during the absence of draft, a fan is installed.