Facing the stove with ceramic tiles is the final stage of construction. It is carried out immediately after the construction of the outbreak or after a time when the decoration has become unusable and needs to be updated. Properly selected and correctly selected cladding performs several functions at once. High-quality and beautiful tiles for furnishing furnaces serves as a decoration of the house, protects the plaster layer from damage, having a large heat capacity, does not allow the masonry to cool. Being a kind of screed, the tile prevents the opening of joints between bricks and the release of combustion products into the room. To cover the stove with tiles so that the structure has been used for decades without repair, you need not make a mistake when choosing the material and technology for its use.

Types of tiles and its advantages

The choice of lining for the furnace is quite limited, since this structure is characterized by high thermal load, significant temperature differences caused by heating during heating and cooling when it is finished. As a result, linear extensions occur that can cause delamination and cracking of the finish. Based on these criteria, you need to choose a facing material and the method of its application.

The most popular types of cladding are:

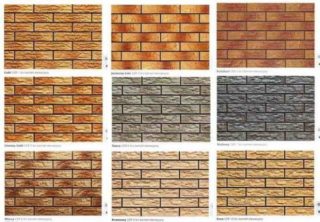

- Brick tile. The product is made of refined clay by pressing, followed by high-temperature firing at a temperature of 1200 ºС. The material is resistant to strong heating and rapid cooling. Due to the same composition with kiln bricks, it has an equal linear expansion coefficient with them. Clinker does not absorb moisture; products of a wide range of colors and textures are on sale.

- Porcelain tile. It is a pressed mixture of crushed granite, sand and light clay. The tile has an attractive appearance, combined with high strength and ease of installation. The finish is waterproof; when heated, it expands in proportion to the laying of the stove. Porcelain tile reliably imitates natural stone, due to which it organically fits into any situation.

- Majolica. Tiles are beautiful, unique and individual. It is produced by firing blanks with a pattern applied to them. During heating, the glaze is baked and gains an attractive sheen. The material is notable for its internal strength, but the external coating requires a neat attitude. The coating is hydrophobic and heat resistant. A wide range of products in classic and ethnic style is on sale.

- Terracotta. This type of finish has a long history of use in facing work. The raw materials for the production are chamotte and clay saturated with iron oxide. The final product has a characteristic red-brown color, perfect for a home. The tile is lightweight, durable and waterproof. The lining quickly warms up and holds heat for a long time. Thanks to its well-thought-out composition, it is immune to extreme heat.

- Terracotta Refractory Tile

- Majolica

- Porcelain Tiles

When deciding on the choice of tiles for the lining of the furnace, you need to consider its combination with the surrounding interior, financial capabilities and construction skills.

Tile Fixing Methods

You can tile the stove in several ways, each of which has its own characteristics, pluses and minuses.

The following options are available for fixing the facing material:

- On factory-made glue.This is the easiest solution if the wet fixation method is selected. The mixture is already ready for use, there is no need to think over and calculate the proportions of the components. It is only necessary to carefully follow the manufacturer's instructions when mixing and using.

- Homemade solution. It is made from Portland cement, PVA glue and salt. This combination provides strength and shape stability of the dried composition. The presence of PVA provides thermal expansion of the material, and salt prevents its rapid drying.

- On a frame made of steel profile. A stainless steel is used, since ferrous iron quickly becomes rusty due to temperature and condensate. Profiles are attached at a distance of 1-3 cm from the base, the tile moves in them, as if on guides. Between the surfaces there is hot air, providing heating of the outer lining.

- On anchors. The fasteners used in the connection of display windows are used. The tiles in them are inserted with the edges so that there are no gaps. After that, the corners are sealed with a steel profile.

- Mounting grid

- Cement composition

- Anchor Structures

- Heat resistant adhesive

Regardless of the fixation method chosen, pre-masonry should be plastered using reinforcement. If this is not done, there will be a risk of opening the seams and the appearance of through gaps.

Tools and materials

Laying tiles on the hearth is a simple event, but for its implementation it is necessary to have a rather large arsenal of materials and devices. To clad the stove with ceramic tiles with your own hands, you will need such tools and equipment:

- roulette, square, level;

- flat and angular steel spatulas;

- grinder, tile cutter, tile cutting string, puncher with drills and mixer;

- mallet, scissors for metal;

- paint brush;

- rubber spatulas.

The list may vary depending on the selected method of fixing the tiles on the surface of the furnace.

To finish the home, you need to purchase the following materials:

- tile with a margin of 20% of the estimated amount;

- heat resistant plaster;

- deep penetration primer;

- heat resistant glue;

- grout for joints;

- plastic crosses;

- steel profiles, if you plan to install on the frame;

It should be borne in mind that the process of facing the hearth is a dirty and dusty occupation. It is necessary to cover all interior items with cellophane film, cover the fireplace with gloves, glasses, and respiratory protective equipment.

DIY lining process

Putting tiles on the stove is possible only after a competent and complete preparation of the base. If it does not meet the requirements for such structures, the finish may fall off after a few fireboxes.

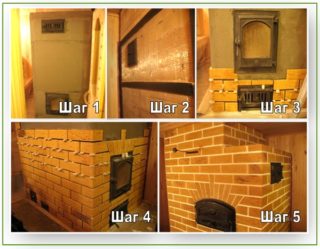

Preparation of the base is carried out in the following sequence:

- Removing old putty. This must be done carefully using a spatula or hammer with a chisel. To make the plaster easier to move away, it is recommended to moisten it well. You can not use a punch, as bricks can crack and seams can break due to vibration.

- To clear a basis of the remains of solution and deposits. This is done manually with a metal brush or power tool with a special nozzle.

- Scrape joints to a depth of 1 cm to ensure that the new plaster is firmly fixed. The quickest way to do this is with a wide-disc grinder on concrete.

- Remove settled dust and stone chips from the surface using a paint brush and damp rags.

- After the base has dried, coat it with a primer several times, making sure that the liquid enters the entire surface of the joints.

- Check the straightness of the walls, top and corners of the structure.If deviations from the vertical and horizontal are detected, such places are marked with beacons. Leveling is carried out by heat-resistant putty and a wide spatula.

- Reinforcement. On a thin layer of refractory glue, the stove must be glued with a metal or fiberglass mesh. This will prevent masonry discrepancy and cracking putty.

- A layer of plaster up to 3 mm thick is applied over the mesh. After drying, it must be treated with an antiseptic and a deep penetration primer. This will improve the adhesion of the material and increase its strength.

After the preparatory stage is completed, tile laying begins.

With the wet method, the hearth should be lined in the following order:

- Install the starting metal profile. It will set the direction of the masonry and prevent the tiles from sliding down.

- Knead the factory or prepare a homemade solution.

- Dampen the back of the tile to remove dust and improve adhesion.

- Put the solution on the tile and distribute it with a notched trowel.

- Stick on the first bottom row using plastic crosses to maintain the same distance.

- Similarly lay out all subsequent rows. The last fragments are sized with a grinder or string.

It is necessary to glue so that no solution remains in the seams. After setting the glue, they are filled with special heat-resistant grout.

When tiling, a special heat-resistant mixture and heat-resistant silicone are used. Gluing is carried out simultaneously with the tension of the wire inserted into the rumps. After installation, an additional pulling of the wire is carried out vertically and horizontally.

The corners are mounted so that the distance between them is 2-3 cm greater than the height of the tile, so that there is room for thermal expansion and free movement of the inserts during installation and repair.

Tile Care

Tile care is not particularly difficult if performed regularly. Immediately after finishing, you need to wipe off the glue with warm water. If it is dry, it is better to pry it with a ceramic or wooden knife.

During cleaning in the house surfaces must be cleaned of dust and dirt. Once a month, the tiles must be treated with a special preparation for washing ceramics. Terracotta should be covered with impregnation. Such funds are sold in specialized stores.

It is strictly contraindicated to use abrasive materials and to strike at ceramics.