The cellar is designed to store vegetables and fruits in raw and canned form. Wine cellars are a separate category. In any case, the room requires a certain climate, allowing you to maintain the desired properties of the products for a long time.

Do I need air conditioning for the cellar

The temperature in the cellar with vegetables should be in the range from +1 to +12 degrees. If the room gets warmer, aerobic bacteria become active and cause food to rot. At minus temperatures, the water that is part of fruits and vegetables freezes, as a result, the taste is lost.

To prevent food from drying out, the air humidity should be at least 85%.

When it comes to canned workpieces, the requirements for temperature and humidity are not so strict. However, in dry air they will last longer.

As a rule, if the cellar is located below the level of freezing of the earth, almost all year round it keeps a temperature of + 6 ... + 12 degrees. However, in particularly hot weather, the room begins to warm up. In this case, air conditioning is needed for the basement.

Climate parameters for wine cellars

To get quality wine, the fermentation of raw materials must take place under certain conditions. Violation of climatic norms will spoil the best grapes. Maintaining a constant microclimate is possible only with the help of wine conditioners.

Standards for the maturation and storage of wine are:

- 75% humidity;

- air temperature from 10 to 14 degrees (set for different varieties);

- total darkness;

- high-quality ventilation;

- lack of shaking.

Indicators should be maintained constantly, without drops and jumps. Otherwise, the winemaker does not achieve the desired taste and aroma.

Household monoblocks and split systems are not able to cool the room below +16 degrees, so special equipment should be preferred. Specialized air conditioners in the wine cellar are ideal for this.

Features of the device climatic equipment for wine rooms

Inverter-type equipment allows you to maintain the required temperature and humidity in a wide range with minimal fluctuations, which is not dangerous for the process.

Air conditioning for wine rooms is a split system. The outdoor unit is carried out, the internal can be built into the wall or hung on the ceiling. The compressor located in the outdoor unit is a source of vibration and noise, so it should be installed away from the wine room. For freon pipeline there are length restrictions, they are taken into account when choosing a place for the outdoor and indoor units. Manufacturers also offer air conditioning for wine rooms with reduced noise, but they cost more.

In order for the outdoor unit to work at temperatures below zero, the package includes a thermal belt, a warming compressor. A number of advanced models have a heating function, which is necessary in the cold season: freezing wine destroys its taste and aroma.

Some variants of climatic equipment for basements are built into the front door, providing its thermal insulation and optimal indoor temperature.

Advantages of air conditioners for the cellar:

- maintaining the optimum temperature depending on the type of wine from +2 to +18 degrees;

- maintaining humidity in the room from 70% to 85%;

- the possibility of fresh air from the street;

- accuracy of temperature value of 0.5 degrees;

- a large selection of options: monoblocks, split-systems of wall, ceiling, channel, cassette types.

There is only one minus of equipment - a high price.

The most famous wine conditioners presented by French manufacturers. These are the brands Fondis and Friax. The technique is specially created for wine rooms and cellars.

Manufacturers offer a fairly wide selection of models. You can choose the right power and design. If the evaporator cannot be mounted in the cellar, ducted air conditioners are installed in the wine cellars. All equipment is located outside, connecting to the cellar room with a duct system.

The only difficulty lurking when installing an air conditioner for a wine room is the water supply. Water must be supplied to the evaporator to maintain a high level of humidity.

Installation specialists will suggest a place for the air conditioner. The more complex the tasks assigned to the masters, the more expensive their implementation.

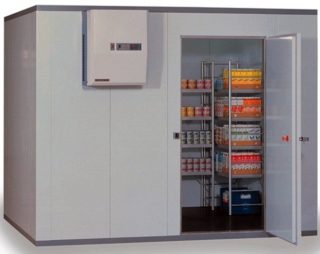

Refrigeration unit

An alternative to an air-conditioned cellar is a refrigeration unit. You can put as many products in it as the average cellar can hold. Reliability and durability of such equipment surpasses air conditioners.

The refrigeration unit can be installed anywhere. As a rule, basement or basement rooms are chosen for these purposes.

Preliminarily, it is necessary to insulate the floor flooring of the first floor and provide ventilation so that stagnant air does not adversely affect products.

Advantages of refrigeration equipment:

- Ease of use. Maintaining a constant temperature allows you to keep food fresh for a long period.

- Temperature adjustment. The user can independently adjust the necessary level of cold in the range of -5 .... + 10 degrees.

- Cost-effective service. After the acquisition and installation, financial costs will be required only for the consumed electricity.

Refrigerator medium temperature 0 ... + 10 designed for storage:

- vegetables, herbs, fruits;

- fresh meat and fish;

- sausage products;

- cheeses and dairy products;

- preserves and pickles;

- wines.

Equipment with a minimum temperature regime is used for medium and deep freezing of berries, vegetables, mushrooms, meat, fish, etc. The air temperature in them can reach -20 degrees.

The refrigerator can be used to store fur products that require temperatures not exceeding +5 degrees.

Refrigeration unit

The equipment is made of polyurethane foam panels using thermal insulation: polystyrene foam, mineral wool, etc.

The operation of the cooling equipment is provided by a refrigeration machine, which can be made in the form of a monoblock, split system or prefabricated unit.

The prefabricated installation is made according to an individual project, therefore it is characterized by maximum efficiency in work. Noise level, degree of reliability and protection, dimensions are determined by the needs and budget of the customer.

Ready split system or monoblock is selected depending on the size of the room.

Terms of Use

Products must be packed in airtight containers so that the smell from them is not mixed and absorbed. Packages must not touch the lid and walls of the chamber.

It is necessary to monitor the operation of the equipment, as sometimes the electricity is turned off, and the installation must be restarted.