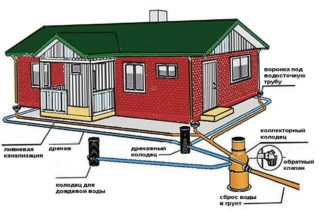

Equipping storm sewers in buildings is a necessary stage in construction or repair. The erosion of the soil around the foundation with rainwater, flood problems shorten the life of the facilities. In the presence of a basement or basement, it is also worth preventing the entry of groundwater into the house. A properly executed storm will solve these issues.

Storm design

To skillfully arrange a storm system, you need to imagine its design and main components. The sewage system includes:

- a network of gutters from the roof of the building;

- water trays or pipes;

- collectors.

A feature of this system is the absence of extraneous influences on the water flow.

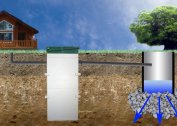

Storms are performed in open or closed form. Open systems are arranged on the surface of the soil. They collect excess moisture and direct it to the collector. If the volume of wastewater is small, then such a design will be rational. Enclosed structures are immersed in soil at a design depth.

Storms make point or linear. The point structure is arranged in the presence of a drainage system in the building. It is equipped with storm water inlets, which are equipped with filters. These elements prevent clogging of the system with foreign objects and debris. The linear system collects water from a larger area on the site.

Requirements for pipes for storm sewers

The movement of water flows through the pipes of the storm system occurs without the use of pumping equipment - by gravity. For this reason, there are no special requirements for internal pressure strength.

- The pipes are reliable enough to support the weight of bulk soil.

- The material of the products is able to withstand operation at low temperatures without loss of properties.

- Pipes are resistant to chemicals.

- The inner surface must be smooth so that the water moves without obstruction.

The material of stormwater elements is selected based on operating conditions and pipeline throughput.

Materials of manufacture

Asbestos cement pipes

A drainage pipe for storm sewage from asbestos cement has many advantages:

- good mechanical strength;

- long term of operation;

- high resistance to decay and corrosion;

- low degree of thermal conductivity of the walls;

- the presence of a very smooth inner surface.

The material has its drawbacks:

- the heavy weight of the products creates certain difficulties for installation;

- low resistance to point mechanical stress;

- it is difficult to reliably make joints of elements and their waterproofing.

In many countries, the use of asbestos cement is gradually abandoned.

PVC

Rigid single-layer pipes are produced from polyvinyl chloride for stormwater with a diameter of 110 mm and 160 mm. They have good technical characteristics:

- Strength - stacked to a depth of 4 meters.

- The smooth inner surface does not interfere with the movement of water.

- A wide range of fittings and fittings - perform the installation of complex systems.

There are significant disadvantages to using such elements. They are produced up to 3 meters long. The rigidity of the material requires a large number of additional parts when making turns and branches, which significantly increases the price of stormwater.

Plastic

Multilayer structures made of various plastics are popular.Components for pipe layers:

- PVC

- HDPE;

- polypropylene;

The inner layer is made of a material that provides a perfectly smooth surface. The outer shell is a reinforcing layer.

- This structure allows the pipe to be flexible with sufficient ring strength. This is of great importance when installing curved structures or systems with many turns.

- There is no need to use additional elements, which reduces the final cost of the entire storm sewer.

- Products are produced with a diameter of 63 mm to 200 mm. Flexible pipes are easily twisted into coils. Buying parts of various lengths is advantageous, since there is no need to install docking assemblies. In addition, the material can be purchased in the right quantity.

Multilayer pipes are used for storms of varying complexity.

Fiberglass

Fiberglass pipelines are often used for large drainage systems. Such products are produced with a diameter of 500 mm. Length is 6 m or 12 m.

Advantages of fiberglass pipes:

- light weight;

- great strength;

- chemical neutrality to aggressive substances;

- environmentally friendly material;

- long service life.

The pipe capacity determines the required size. Typically, a storm sewer pipe diameter of at least 100 mm is used. By length, it is better to choose the maximum size of the elements. This makes it possible to perform fewer joints.

Installation Steps

The shallow laying of storm sewer pipes allows in many cases to perform the device yourself. Complex systems require the involvement of professionals.

Installation of a storm shower consists of several stages:

- The calculation of the pipeline capacity is done based on the maximum amount of water that will fall into the system.

- Implementation of the drawing of the future design with all the elements.

- Sizing of individual parts.

- The device of trenches for pipes.

- Assembly of elements.

Here it is worth considering some points:

- Storm sewage is installed in an open or closed way.

- The stormwater is positioned above the general drainage system.

- The depth of the pipe is recommended below the freezing mark. When this is not possible, the structure is insulated with heat-insulating materials that should be protected from groundwater.

- Free flow of water is provided by a slope device - an average of 10 mm per 1 m. The slope of the pipeline depends on the diameter of the pipes.

The connection of individual elements with each other is performed in several ways:

- Single-layer PVC parts are equipped with internal seals in the form of rings. Installation is simple.

- Multilayer pipes made of plastic are connected using rubber sealing rings. The second option is the use of electric-welded or heat-shrink sleeves.

- Fiberglass parts are connected with special couplings, inside of which sealing rings are fixed. Thus, a strong and tight joint is obtained.

Incorrect calculation of rainfall slope threatens clogging. This applies in particular to the joining points of individual elements and rotations of the structure.

Cost of pipes

The price of drainage pipes for storm sewers depends on the material of manufacture, the size of the products, and the manufacturer.

The best option for a private home is to use flexible pipes with a corrugated outer surface. The most expensive are fiberglass products.

A correctly designed and installed storm sewer system will extend the life of a building or structure without loss of technical characteristics.