It is very difficult to live in comfort without an autonomous sewer in a private house: to bring and take away buckets, you need a lot of time and effort. In addition, it is not possible to use modern household appliances - washing and dishwashers. Therefore, with great responsibility, it is necessary to approach the selection and laying of pipes to ensure drainage from the house, as well as to arrange the supply of water to plumbing devices and equipment.

Current requirements for laying sewer pipes in a trench

Before proceeding with the selection of material for sewerage, it is necessary to familiarize yourself with the requirements of SNiP in order to approximately estimate the costs and scope of work, as well as take into account the difficulty of laying in this region and climatic conditions.

Before proceeding with the selection of material for sewerage, it is necessary to familiarize yourself with the requirements of SNiP in order to approximately estimate the costs and scope of work, as well as take into account the difficulty of laying in this region and climatic conditions.

When laying an external sewage system, the following factors are taken into account:

- Estimated amount of wastewater that is planned to pass through the system during the day. This includes the coefficient of uneven flows, since the majority comes in the morning and evening, when the whole family is at home and uses water, equipment. It is important to consider sedimentary runoff if storm sewers are connected to the main septic tank. The diameter of the pipes in this case should be calculated according to the largest volume.

- Septic tank filling speed. The number of people in the house is taken into account.

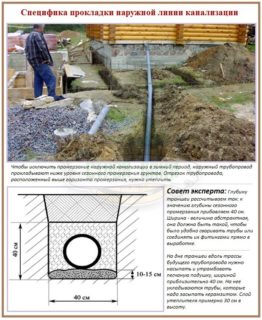

- Climatic conditions and depth of sewerage. According to the rules of SNiP, pipes should be below the freezing level of the soil by 30 - 50 cm, focusing on the upper edge of the product.

- The load on the soil - the highway is in the private or urban pedestrian sector, under the highway with low or heavy traffic. From this it follows that during the arrangement of the sewerage, additional protective mechanisms, such as fittings, pipe bases, stops, should or may not be used.

- Existence of manholes at bends and complex sections of the system with the ability to control.

- Type of sewage - gravity or pressure. The quality and strength of the pipes must be consistent with the pressure level.

- The need for treatment facilities - sand traps, grease traps, grates, filters, sumps.

- The final method of treatment - in a private area it can be an anaerobic septic tank, in the urban system - a biological treatment station using aerobic microorganisms with its own laboratory.

The rules were developed in 1985, but some provisions still apply. Standards for the arrangement of home systems, urban or rural public systems differ.

Pipeline material selection

A large number of sewer pipes are on sale, but this is difficult only for beginners who are going to make gravity sewers for the first time at their site.

Materials must meet the following criteria:

- have a smooth inner surface so that organic particles do not stick and create clogging;

- withstand summer and winter temperatures characteristic of the region;

- be wear-resistant and durable;

- easy to mount and, if possible, light weight.

Stainless steel, cast iron of a new modification with a smooth inner wall, various polymers, black steel - the choice is large, but each material has its positive and negative sides, and is also not always suitable for small summer cottages and small country houses.

Steel, cast iron or stainless steel

Bulky heavy structures are often used to equip urban sewers. In this case, the most suitable material can be selected: there are 4-5 types of cast iron. It serves for a long time, but if improperly installed, if the connection rules are violated, depressurization and leakage may occur.

Stainless steel and cast iron practically do not give in to corrosion, they are chemically inert, therefore the term of operation is from 50 to 80 years. Minus of materials - they are expensive, require large expenses for laying, as well as attracting equipment to lift a pipe that weighs about 100 kg.

Ceramics

The peculiarity of the material is that after firing, the ceramic pipe gains strength, but if it is not carefully loaded, the product will crack. The pipes are coated with a special glaze on top to reduce the degree of exposure to the chemical elements of the soil. Combined with resin and additional fittings. The minus of ceramics is high cost and fragility.

Asbestos cement, concrete

Concrete structures are a cheap material for the installation of sewers, but require large expenses for laying in the ground due to the weight of the products. Concrete has a rough inner surface, so it is more suitable for storm sewers - organics will quickly settle on the walls and cleaning measures will be required.

Asbestos cement is a rather brittle material, therefore it is not used in places with a high load on the soil.

- Asbestos cement

- Ceramics

- Steel

Polymers in the sewer

The main material that is used to equip the sewage system is plastic. There are several types:

The main material that is used to equip the sewage system is plastic. There are several types:

- different types of polyethylene, differing in strength, resistance to temperatures and other factors;

- polypropylene, which is preferred in places where the temperature of the drains is higher - for example, when connecting a washing machine or dishwasher;

- polyvinyl chloride is the most suitable material for external sewage, because it does not withstand high temperatures;

- fiberglass is a very durable material, but weighs more than products from the above polymers.

Most often, PVC pipes are chosen, since they can be laid on the site yourself. The cost of laying a sewer pipe in the ground will be significantly lower.

Tools for assembling and laying sewer pipes

First of all, you need a grinder or a hacksaw for metal to cut plastic pipes with small teeth, so as not to deform the edges.

To comply with the bias, you need to prepare the construction level. A long rope is useful in order to unearth a trench evenly.

If the sewage is cast iron or steel, you need a welding machine with the appropriate solder. To connect plastic, such a device is not required.

Digging trenches is carried out using an excavator or a shovel, if the depth is not too large. To compact the sand cushion, a wooden device with a thickening at the end is used.

Ground pipe technology

The preparatory phase includes the design and layout on the site. This process can be performed independently, if the relief is not complicated, there are few turns and changes in depth. In difficult situations, it is better to entrust the work to professionals so that the system subsequently works stably.

The preparatory phase includes the design and layout on the site. This process can be performed independently, if the relief is not complicated, there are few turns and changes in depth. In difficult situations, it is better to entrust the work to professionals so that the system subsequently works stably.

First of all, indicate the lines along which the pipe will be laid. Then, manually or with an excavator, dig trenches of the desired width and depth.

Laying Technology:

- External sewage is mounted from the foundation. If the joint of the pipes of the internal and external sewage is above the ground, it is necessary to isolate and insulate the area.

- Before joining, the ends of the pipes are closed with plastic bags so that dirt does not get inside.

- If you need to make a turn on the site, revision wells are equipped in such places for the convenience of cleaning and maintenance.It is better to use swivel fittings located at an angle of 45 or 30 degrees, so that drains more easily pass this section of the highway.

- Be sure to check the slope of the pipe. For products with a diameter of 110 mm, 2 cm should be given, for larger ones - 1 cm per linear meter. Pipes with a diameter of 50 mm are laid at a slope of 3 cm per meter.

- To facilitate the joining of pipe ends and fittings, silicone grease is used. Connections are performed manually until they stop, making sure that no dirt particles enter the socket.

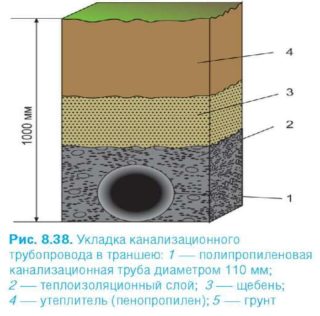

- It is recommended that when laying, immediately insulate the entire trunk, so that in the future it would not be necessary to excavate and finish the work. Insulation is bought with pipes. Particular attention is paid to places where the flow rate is less and there is a risk of freezing water in winter.

- After laying, a sand cushion is poured and tamped.

- The tilt angle is checked again, then the system can be tested. Internal and external sewers are connected, and water is turned on. If it flows into the septic tank, then everything is done correctly.

- Sanding and excavated soil is carried out throughout the trench. Tamping is not carried out - this can lead to deformation of the highway and a change in the angle of inclination.

At the same time, you can start digging a foundation pit under a septic tank. After installing it and strengthening the walls, the end of the pipe is connected using sealant or hot soldering.

It is desirable to carry out work on laying plastic sewers at temperatures above 7 degrees. Polypropylene, polyethylene and PVC do not tolerate cold and become brittle.

Cost of work per meter

The price of laying one running meter of sewage depends on how the products are connected. For example, plastic is assembled with your own hands, but cast iron, steel, concrete are heavier products, therefore, cranes are used for their installation, which is more expensive - rental of special equipment and the work of a crane operator are paid.

The use of welding complicates the installation process. The device consumes electricity, which is also included in the price of one linear meter, plus the work of the welder. The more turns and changes in diameter, the more expensive the highway will cost. The depth at which the work is carried out and the time spent by the hired craftsmen matters.

If you carry out the entire installation yourself, then laying sewer pipes in a trench will cost minimal.