Melt water and precipitation absorb chemical compounds and various solid wastes from the surface of the earth. It is not permissible to dump into natural water sources pollution from industrial enterprises and roads that accumulate in the storm drains of large cities. Wastewater treatment plants free up polluted resources from sand, garbage and oil products. Drinking sources should be protected against toxic waste. To make sewage safe for humans and the environment and prepare it for reuse with a rational attitude to natural resources is the task of local sewage treatment plants.

Application area

The waste water of industrial enterprises, automobile gas stations (gas stations), industrial sites and warehouses is discharged into the sewage system. Before this, the industrial cleaning should be free from pollution at local treatment facilities to a state that complies with the sanitary standards of the Russian Federation.

The arrangement of city streets involves the collection and release of storm water from impurities. In the private sector, two types of VOCs are used: some are intended for domestic wastewater, others - for storm sewage. This is due to different requirements and appropriateness of use. Rain sewer does not require biological treatment, like household waste.

Preparation of modern local sewer systems is carried out in accordance with new requirements. The technology for treating rainwater is based on biochemical processes. The main selection criteria are determined by the conditions of its application and the nature of the pollution. Additional factors:

- laying depth;

- concentration of compounds;

- performance;

- SNiP requirements for the quality of discharged water.

The basis for receiving storm water is a plumbing pipe system that collects contaminated water from storm water inlets - storm drains. Most often these are trays with gutters that are laid along the pavement. According to them, gravity waters rush to the collector - distributor. A variety of storm water inlets are door pallets whose task is to collect pollution from the feet of pedestrians. They are installed near the doors of the building or at the gates.

At the first stage of the drainage system, sand traps are designed to protect the treatment plant from mechanical clogging with stones, soil or debris. Mechanical sumps do not allow clogging of the pipeline and collector assemblies.

Types and size of systems

There are two categories of structures designed to collect storm water:

- closed, from sewer outlets through a pipeline in the ground;

- open, using ground gutters and ditches.

The cleaning system is a horizontal tank made of concrete, metal or fiberglass. The size of structures is affected by:

- the area of the plot from which rainwater is collected;

- amount of precipitation in the region;

- the place of discharge of clarified water.

Sometimes the composition of contaminants, depending on the type of object, requires additional cleaning.

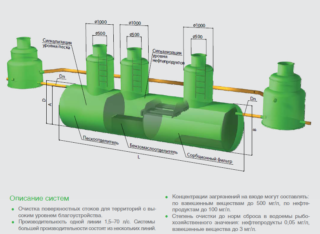

The principle of operation of structures

Local purification devices (VOCs) are made in the form of block-modular installations - sand and oil separators. Tanks that receive drains have hatches for maintenance.Modular devices remove debris, hard-to-settle suspended particles of silt and sand, which are mechanical impurities with a density of 1,500 kg / m3, and oil product wastes in the form of films on the surface of effluents, emulsions and residual conglomerates.

Factory modules have certificates of quality and conclusions from the sanitary and epidemiological surveillance. Designed to work for 10 years.

Cylinders made of low-pressure polyethylene are used, which make up the device body, durable and resistant to aggressive environmental conditions. The sand-oil collector performs a comprehensive sewage treatment in several stages:

- In the sump, large particles fall out under the action of gravity.

- In a thin-layer module, suspended solids are precipitated, and primary emulsion droplets are collected on hydrophobic plates.

- The task of the sorption fibrous filter in the capture of petroleum products that did not stay in the thin-layer module.

- The coalescent module made of polypropylene attracts the remains of fuels and lubricants, repelling water.

Cleaning is completed in a filter with a coal sorbent, which allows catching all types of oil products.

VOC Design

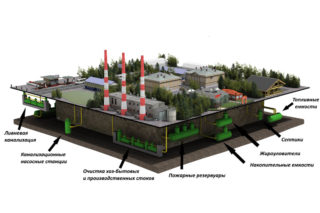

On the territories of industrial facilities and gas stations, melt and rain water accumulate in the tanks, then they are pumped out and transported outside for discharge into the ground or water bodies.

The design of local treatment facilities begins with determining the amount of precipitation and the uniformity of their flow. The choice of modules is affected by the composition of the impurities in the effluent, the depth of soil freezing, and the level of soil water. An error in the design can lead to flooding of the site and destruction of the soil structure in the future. The presence of underground utilities in the area is taken into account.

A scheme of storm sewers is drawn up: the location of channels and gutters for discharging precipitation, pipelines for redirecting sewage to treatment modules. If the system is designed according to the principle of gravity, without installing pumping equipment, installation should be made with an angle of inclination, depending on the diameter of the pipes.

In accordance with SNiP, when designing sewage treatment plants, the sanitary protection zone (SPZ) for the arrangement of sewage is taken into account. It is designed to protect the pipeline from damage, as hazardous effluents can enter drinking water sources and the surface of the earth. The distance to the sources must be at least 50 m, and the security zone on both sides of the sewer pipeline is 5 m each.

In private buildings began to install flowing septic tanks. They are made from several connected sumps and a drainage site, or they buy a finished product.

Manufacturers offer the design and manufacture of devices for internal and external sewage, connecting fittings and pipes, water purification systems from iron.

How to determine performance

To calculate the volume of the structure, use the data:

- precipitation level in 20 minutes depending on the region (determined by SNiP 2.04.03-85);

- area area or roof projection when calculating point rainfall.

The coefficient of surface absorption is involved in the calculation, depending on the type of surface: for asphalt pavement - 0.95; for concrete - 0.85.

Installation of systems

Installation of storm sewers is carried out in accordance with the project. If there is a need to warm the pipeline, the depth of the trench should take into account the sand cushion (20 cm) and the thickness of the insulation made of insulating materials.

Foreign objects are removed from the trench: stones, roots. A pit is prepared for treatment devices - it can be a local block-modular installation made of plastic or a structure made of concrete.A pipeline is laid in a pit and trenches, a treatment device is installed, and the system is connected using fittings.

Every 10 m in sections with a flat surface and at each bend, inspection wells are provided. A sand trap is installed in front of the pipeline at the outlet of the collector. After joining, the joints are sealed. Before filling the trench, the system is tested: several buckets of water are poured. If there is no leakage, the trench closes.

In areas of uneven terrain there are problems connecting to a common highway, since there is no necessary pressure for gravity flow. In these cases, installation of wells for damping the pressure of the sewage system is provided.

If there are no drains, to prevent leakage under the house, gutters are installed to collect rainfall, blocked with grates and connected to the storm sewer system.

The stormwater is not connected to the general sewage system, since it contains chemical compounds unsuitable for biochemical water treatment. In the private sector, this is also not recommended, so as not to overload the sewer system. They try to carry out VOCs in a private house in accordance with environmental safety requirements.