The volume of meltwater and rainfall falling on the roof of a conventional structure can be 100 m3. If water is not removed, it will collect in puddles and destroy the roof and foundation of the house. Storm sewage is a complex system consisting of pipelines and sumps. At the first stage, precipitation is collected in receivers, which include trays for draining rainwater.

Scope of drainage trays with grate

Rain trays are installed in crowded places and vehicles: pedestrian paths, road junctions, train stations and airports. Stormwater is an integral part of construction projects, so the owner of a private house needs to take care of the drainage system himself to protect the property from precipitation.

Advantages of drainage trays:

- durability;

- strength;

- moisture resistance;

- frost resistance;

- resistance to seasonal temperature differences.

A wide range of trays of different sizes made of concrete, plastic and composite materials will allow you to choose the best option for solving the problem of primary rainfall collection.

Materials of manufacture

Water intake trays are manufactured in accordance with approved standards. They can have a rectangular, square or U-shaped rounded shape. On top of the product are equipped with grilles that protect the storm sewer from blockages. Collecting branches and other large garbage, they do not allow passers-by to stumble into the grooves filled with water and additionally add aesthetics to pedestrian and traffic areas.

For the manufacture of rain trays, traditional building materials and plastic are used.

Concrete

In the manufacture of monolithic gutters, fiber concrete is used. This is one of the varieties of cement concrete with reinforcing fibers. The most durable and reliable products with low cost cope with large flows of water and withstand significant weight loads. Fiber concrete is inert to the effects of aggressive chemical impurities contained in storm water, therefore, concrete trays are used to remove precipitation from road surfaces and from the foundations of buildings.

Disadvantages:

- heavy construction weight;

- high cost of transportation;

- installation complexity;

- the need to attract loading equipment.

Another disadvantage is the complexity of installation work, as it requires the involvement of a team of workers for unloading and installation of the storm.

Polypropylene and polyethylene

The smooth surface of plastic products easily passes water streams containing debris. Modern plastics are highly resistant to chemicals. Such trays have a weight of up to 15 kg, so there are no problems with transportation. Products are easy to install with your own hands without involving heavy loaders.

Disadvantages:

- high price;

- low strength.

Plastic products have a limited life. In this regard, they lose to concrete gutters.

Polymer concrete

The combination of the advantages of plastic and concrete makes products attractive to customers. For their manufacture, granite chips or quartz sand are used, epoxy and polyester resins serve as a connecting compound. The resulting conglomerate successfully replaces cement. Products made of polymer concrete are lightweight, and their strength and elasticity increases.Throughput increases compared to rough concrete gutters. They also withstand maximum weight load.

Polymer sandstone

Another modern conglomerate with the addition of polymer chips. It is based on fine sand. After heating to the melting temperature of the composite materials, the mixture falls under the press. Thanks to quartz, the trays gain strength, and the polymer gives elasticity, which increases resistance to mechanical stress. At a cost they are slightly superior to concrete products, but have half the weight.

Cast iron

Heavy and expensive cast iron products have not gained popularity, although the material has good strength, due to which the trays have a long service life.

- Sand Tray

- Polymer concrete

- Cast iron

Drain pan sizes

The gutters made of concrete and reinforced concrete are produced in accordance with accepted standards: their length is 1 m, the height of the structure is from 9 to 76 cm, the width is from 10 to 50 cm.

Plastic trays have the following standards: with a length of 1 m, the width can vary from 14 to 20 cm, and the height from 6 to 30 cm.

Polymer-concrete products: with a length of 1 m, their width varies from 7 to 30 cm, and the height from 5.5 to 12.5 cm.

Drainage trays made of polymer sandstone: with a standard length of 1 m, the width is 140 mm, and the height varies between 7-12.5 cm.

Criterias of choice

The main selection criterion is compliance with the expected load. Trays designed to drain water from car parks and roads differ from storm water inlets for garden plots, private houses and garages. Be sure to calculate the throughput of drainage products.

When choosing the material of manufacture proceed from the feasibility of costs and durability of products. Each tray has its own class, according to which it withstands the installed load.

Class A15 includes trays that can withstand 1.5 tons. They are usually used for storm sewers in private estates, on children's and sports grounds. Class B125 indicates resistance to weight of 12.5 tons. Such products are in demand on roads with little traffic.

Mounting Features

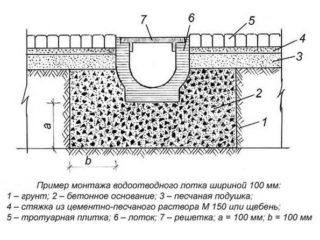

The installation process of storm sewers is quite laborious, but following the above algorithm and observing the rules, you can install drainage trays with your own hands:

The installation process of storm sewers is quite laborious, but following the above algorithm and observing the rules, you can install drainage trays with your own hands:

- Make a plan for the placement of the trench. It is necessary that it has a slope of 1 cm per linear meter for gravity flow of water.

- The bottom of the dug trench is rammed.

- Sand forms a cushion for trays or troughs.

- The bottom and sides of the trench are poured with concrete, on top of which the trays are installed close to each other, for this they are slightly tapped with a hammer to give the desired position.

- Grids are installed on top of the trays at a distance of 5 mm from the ground. At corners, rotary inserts are used.

At the final stage, the seams between the trays are sealed with sealant. If necessary, sand traps are installed before mounting trays.

Cost of trays

The price of products depends on the size, the selected material, the load class, the shape of the lattice - cellular or slotted. The manufacturer reduces prices in bulk purchases.

- Class A complete plastic products can be purchased from 513 to 576 rubles, Park class within 6842-7483 rubles.

- Concrete gutters are bought from 250 to 477 rubles.

- Polymer-sand products range from 422 to 465 rubles, polymer-concrete products from 944 to 1732 rubles.

- Prices for drainage trays with cast-iron grates: plastic class A size 125 * 75 costs 660 rubles.

- Plastic with a steel galvanized grate 125 * 74 in size has a cost of 512 rubles.

Galvanized steel grilles to protect against corrosion. A drainage tray with such a grill has a lower cost, which makes the product more popular.

The consumer often chooses polymer concrete trays, although they have a fairly high price and low adhesion (adhesion) to the cement mortar. However, plastic gutters are the least durable, and concrete products are too heavy.