Products with thin walls that are unstable to shocks and ground movements are not suitable for external sewage, so another type is used - red sewer pipes. They are much stronger and more durable. The market offers many materials that differ in technical conditions. There is an opportunity to choose the type of pipes for autonomous sewage, which will correspond to all parameters.

Purpose of external sewage pipes

External sewage system is a system that delivers domestic wastewater to the place of treatment or disposal. It includes:

- pipeline;

- drives

- wells - revision and maintenance;

- cleaning systems.

Drives are containers that need to be emptied periodically. The main component is septic tanks. They are made of several materials - concrete rings, stone, brick, plastic, steel, cast iron. The cost of the system depends on what material is used, how long it serves, how often it needs to be cleaned so that the sewer works without interruptions.

Viewing wells are part of the sewage system, which are installed in the most problematic places - wiring, bends, places where the diameter of the pipe changes. Equipped with platforms for workers who serve the section of the highway, as well as brackets that act as steps. The well shaft is also made of various materials. Most often, these are concrete rings, but now, when building new sections, builders use plastic, since it is not inferior in strength to steel and concrete structures, for example, polypropylene or polyethylene, and in installation it is much easier and more practical - it does not require welding.

Treatment systems - biological stations, two or three-component septic tanks for wastewater treatment. They are located outside the building, most often installed in the ground, so they must comply with local weather conditions. The industry offers septic tanks for sewage treatment plants of different materials, of different designs - prefabricated and monolithic, so that customers can choose the best option for themselves.

Sewer pipes - the main element connecting all parts of the system. To equip an autonomous home sewage system, special modifications are chosen that, in cold winters and hot summers, do not lose their characteristics, do not clog, and are not subject to corrosion. The easiest to install is plastic and its various types.

Materials of manufacture

Polypropylene structures are one of the most popular in the construction of home water supply, heating and sewage systems. The material has several advantages that compete with more expensive and heavy ones - steel and cast iron:

- service life with proper operation more than 50 years;

- plaque in the form of lime, silt, rust is not deposited on the walls, because the walls are smooth from the inside - substances in the water do not have time to adhere to the material;

- low weight of products that do not require the use of heavy construction equipment;

- you can connect parts from polypropylene using welding or fittings;

- the cost of the material is several times less than steel products and cast iron.

To pick up pipes, you need to know what labeling corresponds to certain conditions - the temperature of the liquid, its chemical composition.

PVC-U pipes for external sewage are made of unplasticized polyvinyl chloride.They are used in arranging artesian wells, wells, sand wells, for home water intake and sewage systems. They have the following characteristics:

- suitable for laying in soil to a depth of 8 meters;

- transport liquids whose temperature does not exceed 78 degrees;

- resistant to water hammer, pressure up to 25 bar from the inside and up to 160 atmospheres from the outside;

- they react neutrally to acids, alkalis, salts, fat, gasoline, but dissolve in acetone, dichloroethane, nitrobenzene;

- do not affect the taste of food liquids, therefore, they are used in enterprises that produce juices, dairy products, vegetable fats;

- do not support combustion;

- can be used at temperatures from minus 50 degrees, melt and go into a fluid state at 180 degrees.

Pipes are light weight, but they do not float when immersed in water - this quality is used in the arrangement of well walls.

Polyethylene is a lightweight, durable material that is used in sewage systems. It has the following properties:

- elastic - does not crack during deformations;

- withstands high temperatures - up to 80 degrees;

- does not change characteristics under the influence of acids, alkalis and alcohol;

- high strength - not damaged during unloading.

The service life is more than 50 years, therefore it is used in urban sewage and water supply systems. There are several types of strength, wall thickness and diameter. The cost compares favorably with metal structures and cast iron.

Steel pipes for sewage are used in environmental conditions where there is a risk of damage when moving soil or the pipe experiences high loads in the form of vibrations - under a freeway with heavy traffic. It has its drawbacks - susceptibility to corrosion. Over time, deposits of iron oxide or limestone appear on the inner walls, which narrows the diameter of the pipe and makes drainage inefficient. Steel products during installation require the use of technology, as they have a lot of weight. In home autonomous sewers, they are practically not used, as they require increased care. If the weld seams burst, the tightness of the line is broken, and expensive repairs are required.

Cast iron pipes for domestic sewage are rarely used, but are sometimes found even in a home autonomous system. Cast iron has both positive and negative qualities - it all depends on the composition and additives, as well as the processing methods. The main disadvantage of cast-iron pipes is the rough inner surface. Over time, a silty layer forms on it, on which organic matter adheres. This narrows the diameter of the pipe, which makes it often necessary to clean the sewer with chemicals that dissolve organic matter.

Cast iron is a rather brittle material, therefore it requires careful handling during loading and stacking. Cast iron pipes are connected by hand using an oiled rope, which sometimes leads to depressurization. The cost of cast iron products is much higher than the price of plastic outer pipes for sewage.

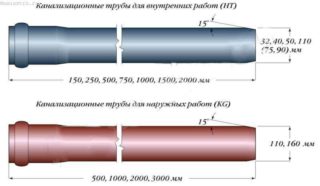

Sewer pipe dimensions

The size of the outer pipe, as well as the wall thickness, are selected based on the length of the pipeline, the depth of the pipeline, the number of household and plumbing devices, as well as the number of people living in the house.

The size of the outer pipe, as well as the wall thickness, are selected based on the length of the pipeline, the depth of the pipeline, the number of household and plumbing devices, as well as the number of people living in the house.

In stores, you can buy red sewer pipes in the following sizes:

- length from 1 to 6 meters;

- in inner diameter from 11 to 50 cm;

- by wall thickness from 3 to 15 mm.

On a private site, outer pipes with a diameter of up to 16 cm are most often used. If sewage runs along the street, then a diameter of up to 20 cm is used. The central highway, depending on the load, can be 50 cm or more.

If there are few turns and bends of the highway on the site, buying long straight products will be cheaper - there is no need to purchase fittings for connecting short segments. You can save on the arrangement of inspection wells, which are also made with the use of plastic products.

Based on the dimensions of the pipe itself, other details of a suitable size are selected:

- adapters;

- tees;

- crosses;

- contours;

- o-rings made of rubber;

- stubs.

The smaller the depth, the smaller the wall thickness you can choose.Consequently, the pipeline will cost less.

For outdoor installation, a corrugated pipe is often used. Its advantage is the presence of stiffeners - inside and out. Inside, small, barely noticeable, outside - large. The most durable are two-layer plastic pipes with a corrugated surface. They are used in areas where soil movement periodically occurs. The ribs do not allow the product to deform, as they increase elasticity. With linear tension, the corrugated surface also affects the integrity and integrity of the line.

The main criteria for choosing pipes for outdoor sewage

Product selection criteria include:

- soil quality on the site;

- depth;

- system pressure - pressure or gravity sewage;

- methods of connecting parts of the trunk;

- single or double layer, the presence of corrugation;

- material of manufacture;

- diameter of the external sewage - depends on the size of the house, the number of water intake points and daily water consumption;

- resistance to external influences - temperatures, ultraviolet;

- domestic sewage or transportation of industrial effluents;

- the chemical composition of the effluent is aggressive or neutral;

- system cost.

One of the main selection criteria is the need to clean the sewer - how often it will have to be done, based on the characteristics of the inner surface.

Installation Steps

Work on the arrangement of the external sewage system begins with the creation of the project and the necessary measurements. After laying the internal wiring, external work begins:

- Digging a foundation pit under a septic tank and trenches under a highway.

- Laying and connecting parts of orange pipes with fittings, tees, adapters, o-rings.

- Installation of inspection wells in the most problematic places.

- To create a support, a sand cushion is used, as well as geotextiles, so that in case of a breakthrough, the sewage does not fall into the ground.

- After connecting all the elements of the system, it is tested in operation. If the water flows normally, trenches and septic tanks are filled with sand and soil, and hatches are installed on manholes.

To correctly calculate the length of the line and the slope of the pipes, it is better to invite specialists. If the works on laying the sewer are performed with errors, this threatens with constant blockages. It will be possible to fix the problem by completely digging up the water supply system, which means a lot of labor, time and money.

Cost of pipes

The size of the product and its brand affect the cost. The density of the outer pipes is initially higher, therefore, the price of the product will be higher. Larger pipes are more expensive than smaller ones.

According to the materials, there is nothing more expensive than ultra-high molecular weight polyethylene. Polypropylene and ordinary polyethylene have an affordable price.

Of the metals, the steel structure will cost more, but there is no need to buy metal for a home autonomous water supply or sewage system. Cast iron is cheaper, but if it is enriched with magnesium, then the price will be about the same as steel.