The classic sewer system works on the principle of gravity water supply through the main pipeline, which is located at an angle. However, such a design can not always be established. An alternative is the use of Sololift pumping equipment, which is distinguished by its compact dimensions, silent operation, easy installation and practicality. The system has a self-cleaning device, due to which the operation of the pump is very simple and does not require extra effort. The equipment manufacturer is the Danish company Grundfos, which manufactures pumping units and their component parts.

Application area

Pumps are used for pumping effluents in buildings where, for technical reasons, it is impossible to establish a sewage system that works on the principle of gravity. The manufacturer offers several models for pumping black and gray wastewater. The following nodes can be connected to the system:

- bathtubs, showers;

- sinks;

- bidet;

- toilet bowls of various designs;

- washing machines and dishwashers.

Due to the small size, Sololift stations can be combined with floor and wall devices, so they do not spoil the design of the bathroom or the bathroom.

Pros and cons of design

The equipment has the following advantages:

The equipment has the following advantages:

- efficient operation even when connected to a small diameter pipeline;

- small dimensions, the ability to mount the device in tight spaces;

- convenient operation;

- a number of advanced models have a vortex design, due to which blockages are not formed in the system;

- no need to use expensive tools for installation;

- compatibility with various types of interior.

One of the disadvantages is the overpriced price of the device. Another problem is a complicated repair, which is difficult to perform on your own. Most owners turn to professional craftsmen to fix the damage, which requires additional costs. On the other hand, with proper operation and initially proper installation, the system rarely needs maintenance.

Design Features

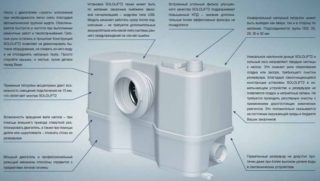

The principle of operation of the Sololift sewer systems is quite simple. The model is used as the main receiver for wastewater, secondary taps are connected using auxiliary nozzles with a diameter of 5 cm, which are located in the lower sector. Inlet lines for drains can be implemented using equipment for a standard sewer network, and the outlet elements used to drain the liquid must have reliable sealing, since pumping is performed under pressure. That is why during installation it is important to purchase branded components, including a check valve and other elements of sanitary fittings.

The principle of operation of the Sololift sewer systems is quite simple. The model is used as the main receiver for wastewater, secondary taps are connected using auxiliary nozzles with a diameter of 5 cm, which are located in the lower sector. Inlet lines for drains can be implemented using equipment for a standard sewer network, and the outlet elements used to drain the liquid must have reliable sealing, since pumping is performed under pressure. That is why during installation it is important to purchase branded components, including a check valve and other elements of sanitary fittings.

In the housing is the pump itself with a separator element and knives that grind large waste. The principle of operation is the operation of an automatic unit that turns on when the tank is full and activates the pump, the device is connected to a standard power supply. Energy consumption even in younger models is small, so the installation of pumping equipment allows you to mount an efficient sewer network in a private house or apartment.

Varieties of the system

The characteristics of the Sololift sewage pump vary depending on the specific model. The manufacturer produces a line of 5 devices, the following types are suitable for installation in the bathroom:

- Sololift2 WC-1.The unit is designed to connect a sink and toilet bowl, power is 620 W, tank volume - 9 liters. A shredder crushing large waste is supplied. The system capacity is 149 liters per minute.

- Sololift2 WC-3. The model is used to create forced-type sewers in cottages and country houses, it has an increased capacity and allows you to connect three additional consumers, in addition to the toilet. The owner can supply such a pump for the operation of a sink, shower, bathtub, bidet or other plumbing.

- Sololift2 CWC-3. The device is equipped with a built-in cutting mechanism, the power is 620 W, and the throughput is 137 liters. This fixture is suitable for installing a wall-mounted toilet or urinal and three optional devices to choose from.

The manufacturer produces models for gray drains, characterized by characteristics and dimensions:

- Sololift2 C-3. Power is 640 watts, per minute the system processes up to 204 liters of effluent. The model is not equipped with a grinder, but allows you to connect an extended range of consumers. It is suitable for draining liquids with temperatures up to 90 degrees.

- Sololift2 D-2. This model is the most compact and lightweight, power is 280 watts, and the throughput limit is 119 liters.

Installation Features

During installation, it is extremely important to ensure the correct angle of inclination of the pumping equipment, otherwise the movement of waste will be difficult. Installation can be performed independently, the equipment is equipped with instructions. To work, you will need several straight screwdrivers (8 and 2.5 mm), tongs with 5 cm opening, a socket and wrench. In order for the system to be able to work without interruptions, you need to complete the installation in the desired sequence. Algorithm of actions:

During installation, it is extremely important to ensure the correct angle of inclination of the pumping equipment, otherwise the movement of waste will be difficult. Installation can be performed independently, the equipment is equipped with instructions. To work, you will need several straight screwdrivers (8 and 2.5 mm), tongs with 5 cm opening, a socket and wrench. In order for the system to be able to work without interruptions, you need to complete the installation in the desired sequence. Algorithm of actions:

- Select the elements of the pipeline, sealing parts, sealant, other consumables.

- Fix the Sololift pump on vibration-proof material, observing the minimum distance to the wall or the connected consumer of 10 mm.

- Connect the required devices (toilet, sink, bath, bidet, etc.) to the outlet pipes.

- Treat joint points and joints with sealant. It is important to choose a substance with waterproof properties, otherwise leaks will quickly appear.

- Secure the outlet pipe with pliers and connect the pump to the mains.

Upon completion of the work, it will be necessary to check the system for operability, test the pump itself, and make sure that there are no water leaks in the network. In the absence of skills or tools, it is recommended to entrust the installation work to specialists so as not to encounter problems with the further use of the sewage system.

System operation and maintenance

Maintenance of the Sololift station involves regular cleaning of filters, water tanks and moving parts. For this, special chemicals are used, the cleaning process includes the following steps:

- Unplug the pump.

- Remove the cover located at the top.

- Pour detergent into a container.

- Turn on the system and drain the cleaning fluid after a few minutes.

- Pump with plain water.

- Close the cover.

The intensity of service depends on the frequency of operation, the number of connected consumers, the quality of drains and other factors. At a standard level of water hardness, the system is cleaned every 3-4 months, the filters change as deposits form. If the internal elements are worn out, it is better to entrust the replacement to specialists.