Ceramic sewer pipes are the oldest underground utilities for wastewater. First applied in ancient Rome and India. Nowadays, due to their properties, they have not lost popularity and, along with analogues of cast iron and polymers, are widely used in various fields.

Specifications

According to the requirements of GOST 286-82, ceramic pipes used for sewage disposal have the following characteristics:

According to the requirements of GOST 286-82, ceramic pipes used for sewage disposal have the following characteristics:

- length: 1000 mm, 1250 mm, 1500 mm, 2000 mm, 2500 mm;

- inner diameter (nominal bore - DN (DN)): from 100 to 1200-1400 mm;

- wall thickness: from 19 to 36-50 mm;

- weight of 1 pipeline - from 30 to 400-500 kg;

- water absorption - products of the highest and first grade absorb moisture no more than 8-9% of their mass;

- strength and water tightness - ceramic pipes are completely leakproof and withstand internal hydraulic pressure up to 1.5 kgf / cm2;

- smoothness and degree of coating of pipe surfaces: coated with chemically resistant glaze;

- straightness deviation: not more than 9-11 mm per 1 linear meter;

- inner diameter of the connecting part (bell) / its depth: from 234 to 1530 mm with a depth of 60-80 mm.

The normative document, in addition to the characteristics of ceramic pipelines, regulates the methods of their testing and acceptance.

Types of ceramic pipes

Depending on the type of connection, ceramic pipes are divided into 2 types:

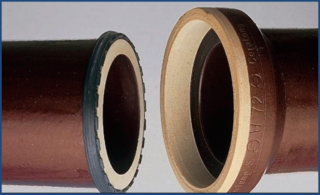

- Bell-shaped - products have at one end a cylindrical or bell-shaped extension (bell);

- Socketless - both ends are smooth and of the same diameter. They are connected using special couplings with O-rings inside.

Because of the reliability and simplicity of its connection, bell-shaped products are more widespread than bell-shaped ones.

Scope of application

Ceramic sewer pipes are used for the following purposes:

- installation of a drainage system;

- laying of external sewer networks;

- installation of sewer city collectors and small tunnels;

- special sewage systems in laboratories and chemical plants.

In addition to transporting and collecting wastewater, ceramic pipes are also used as chimneys in wood stoves and solid fuel boilers.

In home sewer networks, a ceramic pipe is not used due to its large diameter, weight and fragility.

Mounting Features

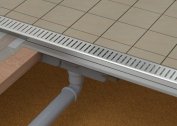

The installation of an outdoor courtyard drain using ceramic pipes with an inner diameter of 100 mm is as follows:

- Digging trenches to a depth of 80-100 cm with a mandatory slope towards the well equal to 2% (2cm / m).

- Filling to the bottom of the ditch a mixture of sand and gravel with a thickness of 15-20 cm with mandatory thorough tamping.

- Laying pipes with a joint and sealing the junction using tarred hemp twine - strands of sealing material are wrapped 3-4 times near the junction 3-4 times, after which a “castle” of bitumen mastic or cement-sand mortar is poured over their turns.

- Filling the pipeline with 4-5 layers of fine sand 10-15 cm thick with a thorough ramming of each.

- Laying over compacted layers of fertile soil.

Installation of pipes begins from the inspection sewer well, laying them in such a way that the bells are directed against the direction of movement of the wastewater.

Despite the seeming simplicity, such a technology for laying sewage is more laborious and complex - it is affected, first of all, by the large weight of ceramic pipes and the need for careful sealing of their joints.

Advantages and disadvantages

Ceramic pipes in comparison with analogues of cast iron and polyvinyl chloride (PVC) have several advantages and disadvantages.

The benefits include:

- Durability - with proper use, a ceramic pipeline can last 100 years or more.

- Environmental safety - products do not contain artificial polymers and other components that decompose in the soil can harm it.

- High strength - can withstand loads much higher than the weight of soil and buildings.

- Resistance to high-temperature and chemically aggressive drains.

The main disadvantages are:

- Fragility - ceramics, although it has high strength, but does not withstand point strong impacts, as a result of which it splits.

- Big weight - a ceramic pipe made of clay sintered under high temperature.

- High cost - prices for ceramic pipes for sewage are 8-10 times higher than for analogues from cheaper and more common PVC. This is due to their more sophisticated production technology and expensive raw materials used. For example, if a PVC pipe with a nominal bore of 110 mm and a length of 1000 mm will cost 150-200 rubles, then the price of a ceramic water stream with a diameter of 100 mm and a length of 1200 mm averages 1,500 -2,000 rubles.

Another disadvantage of ceramic pipes is the need to use a special and rather expensive tool for cutting - a chain pipe cutter.