Flooded neighbors, bad smells in the apartment, water standing in the bath - all this may be the result of improper selection of sewer pipes and installation with violations. You should figure out how to avoid this.

Types of sewer pipes

There are three main materials from which drain pipes for sewage are made: cast iron, ceramics, and plastic. The first two materials are used for the manufacture of risers, sometimes they can be found in the wiring of old apartments and houses, external networks made of ceramics are also preserved. Plastic is a more modern material. It has its drawbacks: worse heat resistance, noise insulation properties. However, polymers are characterized by durability, reliability, low cost and ease of high-quality installation.

In practice, two main types of plastic are used: polypropylene and polyethylene. Polypropylene has high heat resistance, it can be used in homes with a drain of hot water. Polyethylene is suitable for outdoor sewer systems laid underground.

Dimensions and design

Pipes are distinguished by their outer diameter, length and wall thickness. Diameter is used to select fittings. Wall thickness is a less important parameter. In accordance with the sewer project, a specification is drawn up: how many and what pipes are required for the facility, how many connectors and gaskets are needed for them, clamps, other nodes.

Based on the needs of one family, the diameters of 40 and 50 mm are used when laying a regular drain network, and 110 mm for flushing toilets and laying risers. 40 mm is only suitable for separately connecting a washing machine or dishwasher, 50 mm is suitable for all other cases. Such diameters allow you to clean the drain with a plumbing cable without any problems.

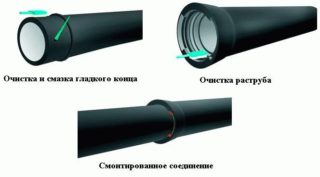

Pipes can have a straight or bell-shaped design. Straight splices along the length using fittings. For bell-shaped fittings are not needed - you can get a system of any length without using any connectors.

Smooth sleeves are usually used when laying horizontal wiring, bell-shaped ones - for laying risers. Corrugation is also used. It is convenient to use to connect the sink, household appliances.

Connecting elements

When laying a socketless pipe, various fitting connections are required:

- drives;

- tees and crosses;

- squares;

- bends;

- revisions;

- adapters.

Squares are found in increments of 15 degrees, usually using angles of 45 degrees. Turns of 90 degrees are undesirable, as the likelihood of blockages increases. They also try to set the bends not straight, but at 45 degrees, taking into account the possibility of cleaning through the opening of the plumbing fixture, the flow from the branch should enter along the stream in the main pipe. Revision are built into other fittings. Adapters are asymmetric - the smaller hole should be higher during longitudinal installation.

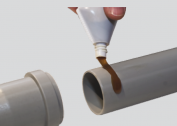

All connecting elements have gaskets that provide tightness. They must exactly match the diameter of the pipe and the type of fitting.

Installation of pipes of the internal sewerage

Before proceeding with the installation, you should have a project on hand. It is done in accordance with the location of plumbing fixtures, the design of the room, the location of the main risers in the house. You can order a project from professionals with a license and work experience, but for a private house you can do it yourself - draw up a drawing and a specification for it.

There are two basic rules for installation: to ensure a slope of at least 1% and mount without narrowing the diameter.In practice, they make 2%, with a margin, but no more. Installation without narrowing the diameter implies that it is possible to exit from a 50 mm network to another 50 or 110 mm network, but not at 40 mm.

Pipes are laid according to the drawing, by marking on the walls and floor. Everything must be fixed on clamps, adjustable supports and racks. Fasten through each meter, but not less than two points on one segment. Access to revisions should be provided, cleaning with a cable is thought out. Only one pressure pump is allowed per line, that is, the washing machine and the dishwasher must have different entrances to the riser.

Siphons should be placed under the sinks or hydraulic locks made of corrugated pipes to be installed so that odors do not penetrate the room.

Use a special roller cutter. The place of the cut is cleaned with a file, they perform the same chamfer. Having lubricated the gaskets of the compound with petroleum jelly, insert a pipe into them and fix them into the pre-installed clamps for marking. Some types of toilet fittings require the additional use of silicone sealant. At the last stage, water is turned on and all joints are checked for leaks.