Concrete drainage trays are the main element of the central stormwater drainage system. Most often they are used on autobahns, runways, in parks. Depending on the type of reinforced concrete drainage tray, its dimensions and shape change. But in general, the technical characteristics of the products are identical.

Scope of reinforced concrete drainage trays

Basically concrete goods trays are used for the device of storm sewer channels on solid surfaces. For drainage of groundwater, special drainage pipes are used. Reinforced concrete gutters are used for such purposes:

- storm water disposal at urban sites: parks, tracks, paths;

- sewage disposal inside industrial halls;

- cable line laying;

- installation of hydraulic structures;

- laying of the pipeline.

As a rule, concrete trays are rarely used in private construction, as the soil tends to heave in the snowmelt season. From this, the product may shift and even break.

Types of reinforced concrete trays

Classify reinforced concrete elements according to the method of their installation: horizontal and vertical.

Classify reinforced concrete elements according to the method of their installation: horizontal and vertical.

Types of destination:

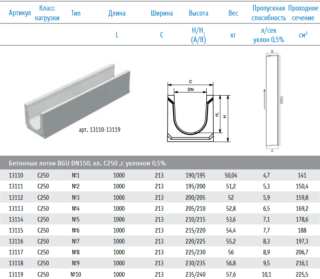

- C250. Designed for light load. Used on a small roadway, pedestrian paths in the park.

- D400 They have a greater load than their predecessors. These are designed to drain storm water from heavy traffic roads, gas stations.

- E600. Used for large volumes of rainwater. More often they are mounted in production and on highways.

- F900 The most powerful. Designed for stormwater on the runway.

As for the dimensions of reinforced concrete trays for storm sewers, their length is often 1 m. The inner diameter varies from 100-500 mm, depending on the class of the product. The form of reinforced concrete products is a rectangular or circular section.

Specifications

All reinforced concrete trays are manufactured in accordance with GOST, since they have high expectations regarding strength and durability. For the manufacture of gutters, special reinforced concrete with a density of 2400 kg / m3 and cement grade M 250 are used. As a result, the finished product has the following characteristics:

- high strength to any mechanical stress, both static and dynamic;

- inertness to temperature extremes;

- weight, which varies between 25-3000 kg;

- the height of the walls of the gutter is 6-160 cm;

- water tightness;

- resistance to aggressive environments.

Due to the high mass of a unit, it is necessary to use special equipment for styling.

Mounting Features

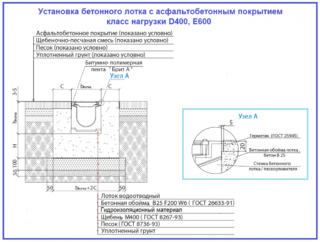

Reinforced concrete trays are laid in the following order:

Reinforced concrete trays are laid in the following order:

- They dig a trench of the right size. Channel parameters must exceed the dimensions of the tray by 30 cm on each side and height. In the future, this space will be filled with a concrete pillow.

- The soil at the bottom of the trench is carefully rammed and a layer of sand 10-15 cm thick is poured onto it. It is also well compacted.

- A layer of concrete mortar with a thickness of 15 cm is poured onto the bedding. It is allowed to dry completely.

- Reinforced concrete gutters are laid on a dried base using special equipment. They are joined together, all joints are treated with bitumen sealant.

- From the outside, the trays are poured with concrete mortar on the sides.

- The drainage channel is docked with central stormwater, the top of the gutters is covered with protective cast-iron or steel gratings.

When laying reinforced concrete trays, a slight slope towards the main receiver should be observed. Then the water will be transported by gravity.

Advantages and disadvantages

For reinforced concrete gutters, such positive aspects are inherent:

- High resistance of the material to aggressive environments.

- Corrosion-resistant properties.

- Long service life - 50 years or more.

- Resistance of concrete to temperature changes, including the effects of minus indicators. With repeated freezing-freezing, the material does not lose its operational properties.

- Inertness of concrete to mechanical stress. Exceptions are point strikes of great strength.

- Environmental friendliness of products. Concrete does not emit harmful fumes to the environment.

- Perfect smoothness of the inner walls due to the addition of polymers to the solution in the manufacture of trays.

The relative disadvantages of reinforced concrete gutters include their weight. However, it can also be considered a plus. Because even heaving soil will not be able to move them from their place.

The cost of reinforced concrete trays

The prices for reinforced concrete drainage trays depend on the size and brand. Table of approximate prices:

| Tray mark | Length of the product | Product Width | Product Height | Tray weight | Price, rub.) |

| L-10-5 | 1000 mm | 500 mm | 230 mm | 200 kg | 950 rub |

| L-1-7 | 1100 mm | 390 mm | 370 mm | 150 kg | 1100 rub. |

| LV-68-30 | 680 mm | 300 mm | 340 mm | 90 kg | 1780 rub. |

| L-300 | 2950 mm | 540 mm | 430 mm | 660 mm | 3200 rub. |

The cost of reinforced concrete trays may vary slightly depending on the region and the manufacturing company.