Sewer pipes are located underground. They need periodic care and control. There are special facilities for this - viewing wells. They are especially relevant in the urban sewage system - more garbage gets there and blockages occur more often. In standalone home systems, they are also mounted for easy system maintenance.

What is a manhole

Sewer inspection well is a round shaft through which repairs are carried out and access to the most structurally difficult places is carried out:

Sewer inspection well is a round shaft through which repairs are carried out and access to the most structurally difficult places is carried out:

- inlet and outlet pipes with different sections;

- a change in the slope of the pipe or a large difference in relief;

- several pipes of small diameter are connected into one wide trunk;

- couplings;

- pipe turns or changing the direction of fluid flow;

- installed pumping equipment or pressure reducers.

On direct sections of the highway, wells are installed in increments of 50 m.

Scope of application

Small diameter shafts are used in home systems. For city sewers, wide cameras with steps are used to accommodate two people.

For the purpose of use, wells are:

- Inspection - serve to inspect problem areas.

- Drainage - collect water during the repair of underground utilities, then pump it out from there.

- Adjusting - are located above cranes and latches.

- For equipment - they contain pumps, sensors, meters, in some cases heating cables.

Materials for inspection wells are selected depending on where the object is located and what its purpose is.

Types of inspection wells and their design features

By design, inspection wells are:

- differential - put in places where there is a gradual decrease in the level and depth of the pipeline;

- linear - for straight sections;

- rotary - are located where the pipes change direction;

- nodal - at the joints of several pipes;

- filtration - for disposal of effluents through the ground;

- control - at the junction of different types of sewers.

- Turning

- Control

- Linear

- Nodal

- Filtering

- Overflow

Differential wells are of several types. They are designed to reduce or increase the speed of movement of sewage through sewer pipes. Installed:

- in places where it is necessary to increase or decrease the depth of the pipeline;

- inside underground structures;

- if the height difference between the inlet and outlet pipes is more than three meters.

Differential wells are multistage, fleeting, with a vertically located pipe, water-drilled. In autonomous private sewage systems are not used.

Filtration shafts are designed for wastewater treatment. Often used in private septic tanks. Norms of SNiP imply that filtration wells should be located above the groundwater level by at least a meter. This takes into account the composition of the soil. For sandy soils, the filtering area is 1.5 m, for sandy 1 m.

Control - located at the junction of the connection of local and city sewerage, the factory system and urban, autonomous private and urban.

Rotary and nodal shafts help control potentially complex areas where there are joints of several pipes or there is a danger of depressurization of the system. Branch pipes are located at one level.

Linear have one pair of nozzles, which are located opposite each other.Designed to control direct sections of the highway located at the same level. The distance between the inspection wells is 10 m.

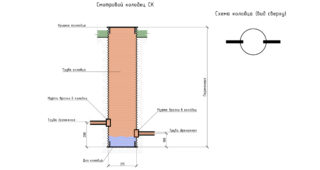

Regardless of the type of construction, inspection wells consist of the following elements:

Regardless of the type of construction, inspection wells consist of the following elements:

- hatch - upper part;

- neck;

- mine - a working chamber, where the craftsmen go down the stairs for repair work;

- the tray where the inlet and outlet nozzles are;

- the bottom is a concrete structure.

On sale there are wells with various levels of inlet and outlet openings.

Revision mines are made of materials that are most relevant for a given section of the pipeline:

- concrete rings;

- plastic;

- brick;

- stone.

Most often, concrete and plastic corrugated products are used, since they have a large resource of work. Especially in the factories of reinforced concrete structures, parts are produced from which mines of various sizes are assembled.

Brick and stone structures allow fluid to leak and smell.

The shape can also be different - round or rectangular. The height of the tray depends on the diameter of the largest pipe that is connected to it.

Current installation requirements

When arranging inspection wells, special attention is paid to the following parameters:

- In urban systems, a mine must accommodate one adult with a set of tools.

- The main material for the manufacture of hatches is cast iron for urban communications and plastic for private sewers. The weight of the hatch located on the carriageway is 134 kg, for sidewalks no more than 80 kg.

- The size of the neck should allow the use of cleaning devices.

Compliance with sanitary norms and installation rules allows you to avoid accidents and sewerage breakthroughs, as well as create conditions for the smooth operation of monitoring equipment inside the highway.

Installation Steps

To install the audit on an autonomous pipeline, you must:

To install the audit on an autonomous pipeline, you must:

- Align the location of the viewing shaft with a general sewage plan.

- Make markings on the site. If there trees or shrubs grow, and also there are utility rooms, they are demolished, clearing the place.

- Provide access to vehicles if the wells are concrete.

When everything is ready, you can begin to dig a pit along the diameter of the shaft. The bottom is leveled and covered with crushed stone, rammed. Further:

- The foundation is laid - a concrete slab or a homemade screed 20 cm thick.

- A tray is equipped. Pipes are embedded in concrete and sealed with bitumen.

- When the structure hardens, you can put the top of the rings. The joints are sealed with bitumen after installation on each other.

- A floor slab and a neck are installed. All joints are rubbed with cement mortar.

- In the lower part, clay is provided with a water lock 50 cm above the nozzles, 30 cm wide.

- Pipes are connected.

- After falling asleep, the hatch is installed at or above ground level.

When installing a plastic well, the sequence of actions is the same, but the weight of the products is much lighter, so a crane is not needed. For a plastic construction, there is no need to make a water lock, since the product itself is tight. Due to its light weight, plastic is subject to displacement when the soil moves, therefore, in its design there are special chambers below, where concrete is poured.

Due to their constant presence in a humid environment, products may leak. This does not happen due to marriage, but because of improper sealing or its absence. To seal joints, three types of insulating materials are used - bitumen-polymer, cement-polymer, polymer. A gas burner is used to dock with the main product.

Manhole prices

The cost of arranging inspection wells is usually included in the general price list if sewers are made at the stage of building a house.Depending on the material and the number of mines, you can make a preliminary calculation of how much the sewage system will cost “by all rules” and the economy option. On a complex site, the lack of access to the highway results in additional costs for repairs and professional cleaning. Therefore, saving on revisions is not recommended.

The price for a manhole plastic well of a simple design is usually lower than for concrete products. In addition, there is no need to rent construction equipment. On the other hand, concrete structures are much more reliable if they are correctly installed and sealed.