Previously, wells were laid out of reinforced concrete rings or bricks, but the building structure did not provide one hundred percent tightness. This led to the destruction of the walls of the structure and the penetration of soil water. The usual material was replaced by durable polymer rings, with the help of which it was possible to solve this problem. Installation of wells was simplified due to the low weight of the elements.

Definition and purpose of plastic sewer rings

Used products from various plastics for household needs. Of them are mounted:

- reservoirs for drinking water, where water is pumped with a pump;

- wells, in the base of which the device is installed - throw, with holes for water outlet;

- absorption or drainage facilities, a filter layer of sand and gravel is poured onto their bottom;

- tanks for rainwater;

- cameras for placing power cables, couplings and fiber optic equipment;

- viewing sewer wells, which are installed in places of branches, turns, changes in slopes and diameters;

- sedimentation tanks.

Elements from polymers are widely used in the arrangement of septic tanks and drainage systems, since they are durable, flexible and are not a source of environmental pollution. All products are manufactured in accordance with GOST. Specifications vary by use. So that the elements do not deform under the pressure of the soil, from the outside they have stiffening ribs. Various additives give plastics resistance to freezing temperatures.

Plastic rings are divided into several types, depending on service options:

- viewing;

- inspection;

- operational;

- served.

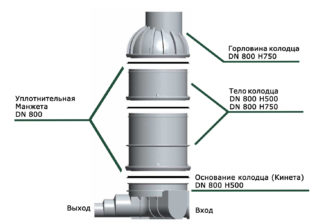

For a complete set, for sale there are kinets (bases), covers, integrated trays for external connections, hatches and necks. There are ready-made solutions: wells and septic tanks.

Production material

Plastic elements are made of polyethylene, polypropylene, PVC, polymer sand mixture and fiberglass. Each of the options has its own advantages and disadvantages.

Polyethylene

Durable plastic withstands temperatures ranging from -50 to 70 degrees. The layered structure contributes to increased strength. The material is resistant to aggressive environmental influences and quietly tolerates frosts. Simple installation, low cost, the ability to use in any region contributes to the popularity of polyethylene rings, from which they make containers for drinking water. Their walls do not rot, the aquatic environment does not silt.

Polypropylene

Products are durable, with high wear resistance, frost-resistant, do not deform when freezing liquid, and are inert to chemical compounds. Temperature limit of work is up to 140 degrees.

Fiberglass

Raw materials contain different resins. Fiberglass withstands the effects of the most aggressive chemical compounds and has a high cost.

PVC

Fire resistant material resistant to chemicals and ultraviolet radiation. Rings are intended for telecommunication facilities, as they withstand mechanical loads from approaching vehicles.

Polymer sand

They are made from a heat-treated mixture of plastic and sand, therefore they acquire the properties of the constituents of the composite mixture. Lightweight, airtight, guarantee 100% exclusion of leaks, have great rigidity and durability for about 50 years.It is advisable to install in areas with heavy clay soils.

The disadvantage of polymer sand structures is the high cost. Products cannot be used in wells with drinking water, as they contain recyclables. The weight of a single element is about 60 kg, so a special technique is used during installation.

Sizes of Plastic Rings

The diameter of the rings made of plastic can vary from 600 to 1500 mm, and the thickness is 6, 8, 22, and 55 mm. The deeper the shaft, the stronger the product should be.

Depending on the specifications, the price changes. The diameter is selected smaller than the shaft by 0.15 m. When arranging telecommunication and drainage facilities, products with a cross section of d800, d900, d1500 are selected, for drinking tanks: d680, d800, d900. The dimensions of the polymer rings for sewage are from 1000 to 1500 mm to allow an adult to go down to revise the operation of the drainage system.

There are 50, 100 and 150 cm in height of the ring.

One-piece constructions are used for septic tanks, shafts and restoration of concrete wells. The wall thickness is 6 mm, the height can reach 5 m, and the diameter of the cross section is 95 cm or more.

Advantages and disadvantages

The use of plastic products has its advantages:

The use of plastic products has its advantages:

- resistant to corrosion;

- provide tightness and reliable durability of connections;

- well tolerate vibration, mechanical stress and displacement;

- plasticity of the material allows you to install structures under the roadway, as the rings are not deformed and do not move;

- the installation of plastic elements does not require certain weather conditions, they are not afraid of frost and a high level of groundwater;

- tightness is not affected by adverse conditions, such as freezing, and possible shrinkage;

- easy installation implies the possibility of any design solution, since the rings can be cut and welded;

- during installation, heavy equipment is not required, which reduces the cost of their installation;

- there is the possibility of tight entry of other elements: cables and pipelines;

- in the polymer walls there are no pores in which microorganisms would develop.

The disadvantages of polymer products:

- expensive welding technology;

- installation of monolithic rings with large dimensions requires a technique;

- do not tolerate falling and mechanical shock to the walls;

- during the flood, loose rings float.

An alternative is corrugated pipes.

Installation Steps

Installation of plastic rings occurs according to the scheme:

- they take out the soil from an area exceeding the size of the elements;

- before installing the well, pour a 15 cm pillow of crushed stone;

- installation of the structure begins with the tray part;

- conduct pipes and seal connections;

- rings are placed on the tray, pressing the board until a characteristic click is heard;

- sand is poured from the outside of the structure;

- formwork is collected on the surface and poured with concrete;

- at the final stage, close the lid.

The ring joints are made using grooves, threads, silicone gaskets and welding.

Price of plastic sewer rings

The cost of the rings depends on the material. The cheapest are polyethylene. Optimal in cost and quality - polypropylene structures.

A polyethylene ring with dimensions (diameter, thickness, height) 950 * 8 * 1500 costs 21 thousand rubles, with a size of 1900 * 8 * 3000 it will cost 71 thousand rubles. Polypropylene products with the same parameters are sold in the range from 25 to 83 thousand rubles.

A polymer sand element costs from 1.2 thousand rubles, in the form of a cone - 2 thousand rubles.

Prices for plastic septic tanks for sewage from 13 thousand rubles. with a volume of 1 m3.