Domestic and industrial effluents sooner or later fall into rivers and lakes, which cause the death of living organisms, as well as bacteria that utilize organic residues. This problem is relevant on a global scale. The infamous Pacific garbage spot holds more than 350 million tons of garbage - plastic, resin, glass, which got there along with currents from populated shores. It is constantly growing and poses a threat to the life of all marine inhabitants.

Urgency of the problem

Wastewater can be divided into domestic and industrial. Household - this is the result of human activities, products of his existence. These include primarily sewage. When it gets into the water, dirty drains reduce the amount of oxygen, contribute to the multiplication of infection, parasites. Eating such water is extremely dangerous.

Wastewater can be divided into domestic and industrial. Household - this is the result of human activities, products of his existence. These include primarily sewage. When it gets into the water, dirty drains reduce the amount of oxygen, contribute to the multiplication of infection, parasites. Eating such water is extremely dangerous.

The level of wastewater treatment depends on the quality of equipment that massively filters and disinfects the liquid, returning it to water bodies or back to the city’s water supply system.

Industrial waste is also hazardous. These include:

- waste water from enterprises saturated with toxins;

- effluents after agricultural work containing phosphates, nitrates and other minerals;

- waste water with inorganic waste - sand, soil particles, salts of heavy metals.

Industrial liquid is conditionally divided:

- according to the degree of toxic effects;

- concentrations of hazardous substances;

- acidity;

- composition.

Substances are divided into conservative and non-conservative. The former do not react with other components, do not form new chemical bonds. They are difficult to remove - these are salts of heavy metals, radioactive elements, phenols and pesticides. These substances practically do not decompose. Non-conservative components of dirty water can be processed over time by the biological method - anaerobic bacteria - these are organic residues.

There are many ways to treat wastewater. Depending on what needs to be removed from the water, certain technologies are used. For example, to clean the home sewage system, it is enough to build a two-chamber reservoir and launch anaerobic microorganisms. Water in this case is cleaned by 70% and goes into the ground, where the process of sedimentation of suspended particles and organics continues.

Stages of cleaning

So that the drains can be safely drained into natural reservoirs, it is subjected to four types of treatment in the following sequence:

So that the drains can be safely drained into natural reservoirs, it is subjected to four types of treatment in the following sequence:

- Mechanical At this stage, the separation of insoluble residues and solid particles occurs. Various grates, screens, filters, sand traps, grease traps are used. The width of the holes in the grate is a maximum of 1.5 cm. Mechanical wastewater treatment also has several stages. After the grate, the effluents fall into a sand trap, where fine solid particles, mainly sand, are deposited. The next stage is the grease trap. Fat is lighter than water, therefore it is collected on the surface, from where it enters a special tank and is removed.

- The biological type of treatment involves the use of various microorganisms, earthworms. They are able to utilize soluble organic matter and turn it into a safe substance. Aerobic and anaerobic bacteria are used. Some work in the presence of oxygen, while others do not need it. During anaerobic fermentation, methane is released - a combustible gas, which, after receipt in the bioreactor, is purified and used for domestic or industrial needs.

- Physicochemical stage.Here the removal of suspended particles occurs, mainly by gluing them into larger ones - coagulation. There are many methods - flotation, centrifuge, evaporation, sorbents, aeration (oxidation) and others. Physico-chemical methods of wastewater treatment allow you to remove all soluble finely dispersed substances from the liquid. The result is industrial water, ready for shipment to water. Drinking such a liquid is not recommended.

- Disinfection is the final stage. The most common methods are ultraviolet irradiation, ozonation, and chlorination.

In Russia, the main method of disinfection is a 30-minute exposure to chlorine. In Europe, this method has long been banned. After purification, it is theoretically possible to drink water, but it is better to use additional treatment: filtration at home or boiling.

Waste water

In some cases, wastewater is not treated, but disposed of. For this, the fire method is used - cheap and universal, in which dirty effluents fall into a lit torch. Water evaporates, and solid particles burn out. This forms water and carbon dioxide. The disadvantage of this method is that it consumes additional fuel resources.

In some cases, wastewater is not treated, but disposed of. For this, the fire method is used - cheap and universal, in which dirty effluents fall into a lit torch. Water evaporates, and solid particles burn out. This forms water and carbon dioxide. The disadvantage of this method is that it consumes additional fuel resources.

Dispose of the effluent by the chemical method, achieving precipitation, after which other chemicals are used and the precipitate is broken down into simple components. This method is used to purify water in the production of synthetic polymers.

Norms for water purification

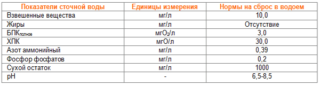

According to the law, before the spent liquid gets into water bodies, it must be identified for the presence of harmful substances. For this, the estimated acceptable level of contamination is measured, requirements are set out in which way the liquid must be cleaned.

According to the law, before the spent liquid gets into water bodies, it must be identified for the presence of harmful substances. For this, the estimated acceptable level of contamination is measured, requirements are set out in which way the liquid must be cleaned.

Considered:

- environmental burden;

- permissible pollution parameters;

- amount of wastewater;

- frequency of releases to water bodies.

The capacity of the treatment plant should correspond to the volume of wastewater produced.

Main methods

The sewage treatment system must work comprehensively to completely remove all harmful and toxic substances. The use of any one method does not give a one hundred percent result.

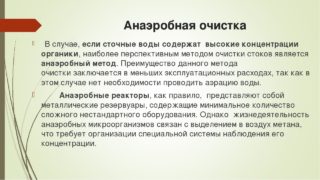

Anaerobic bio-treatment

It is carried out using bacteria that receive energy without the use of oxygen. This is the most cost-effective option, which allows you to bring the level of wastewater treatment to 90%.

It is carried out using bacteria that receive energy without the use of oxygen. This is the most cost-effective option, which allows you to bring the level of wastewater treatment to 90%.

The most effective system in domestic sewage systems, where the fecal mass is discharged. Anaerobic microorganisms are added from concentrates that can be bought at the store. At the same time, it is possible to equip the reception of methane gas, which is released during the processing of organics. A bioreactor is an additional plus of the method. In order to get a clean gas capable of burning, it must be cleaned of moisture and carbon dioxide.

Such complex installations are used in households where animals and birds are raised. With large volumes of raw materials, the bioreactor pays for itself within a year, given that the owners use gas and sell organic fertilizer.

The storage, where the primary effluents fall, is called a digester. At the bottom is activated sludge, which is a granule - a community of bacteria. Microorganisms reproduce slowly, so it is important to maintain optimal conditions for their survival. The temperature should be within 30 degrees. In the process, it becomes necessary to pump out part of the microorganisms. This is done manually or using a cesspool machine. The substance is safe - can be used to feed livestock or as fertilizer on the site, as it contains a large amount of minerals.

The disadvantage of anaerobic cleaning is the low speed of the processes and the need for additional measures to remove organic components.The equipment is expensive, bacteria require constant monitoring of the temperature of the environment.

Aerobic wastewater treatment method

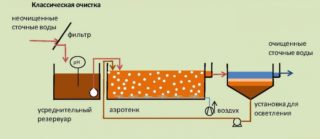

To continue cleaning, the wastewater from the digester is sent to the aeration tank, in which aerobic bacteria continue to work. The process is faster here. Microorganisms multiply more actively due to the presence of oxygen.

To continue cleaning, the wastewater from the digester is sent to the aeration tank, in which aerobic bacteria continue to work. The process is faster here. Microorganisms multiply more actively due to the presence of oxygen.

It is desirable that anaerobic and aerobic methods are used together, since aerobes complete the biological treatment process.

The equipment is an open container - most often a rectangular reinforced concrete structure, which gets liquid previously purified from solid organics. To increase the bacterial population, it is necessary to increase the oxygen concentration, which requires the installation of additional equipment.

There are certain requirements for the quantitative composition of bacteria. For example, the simplest organisms eat bacteria, eliminating old cells and very overgrown certain populations.

Minus installation - high price. It is also necessary to find a suitable place to install both tanks.

Chemical and physico-chemical methods

Chemical methods are most often combined with mechanical methods, since individually they do not give the desired degree of purification. Drugs are used that neutralize harmful substances or oxidize them to safe compounds, which are then captured by mechanical filters or devices.

Chemical methods are most often combined with mechanical methods, since individually they do not give the desired degree of purification. Drugs are used that neutralize harmful substances or oxidize them to safe compounds, which are then captured by mechanical filters or devices.

If the effluents are saturated with acidic components, they add alkaline substances - lime, hydroxides, soda. If alkaline stock liquids come, then they use acids - sulfuric or hydrochloric. The result is precipitation in the form of salts. A pH meter is used to control acidity.

Ozonation is a chemical purification method, the essence of which is in the oxidation of organics. The process is fast - in a short period of time you can clean large masses of water.

The minus of the method is that before ozonation it is necessary to carry out purification from solid large impurities, which is usually done in digesters and aeration tanks. Energy costs for this technology and reagents that are designed for certain ions, for example, iron or manganese, are also high.

Physico-chemical methods are used when not only soluble, but also suspended particles are present in a pre-purified liquid. The main ones are:

- Flotation - pneumatic, pressure, mechanical, electric. As a result of the interaction of air bubbles and suspended particles, flotation complexes arise that float to the surface in the form of foam and are removed by the next step.

- The ion exchange method is based on the replacement of some particles by others. Cleaning is carried out with ion exchangers - substances like synthetic resins.

After several cycles of application, the resin must be regenerated to remove the contaminated layer. Various cleaning schemes are used, which depend on the type of contamination and the concentration of harmful substances.

Mechanical methods

Sand traps for wastewater treatment separate liquids from solid insoluble particles - slag, glass, sand.

Sand traps for wastewater treatment separate liquids from solid insoluble particles - slag, glass, sand.

For high-quality separation, it is necessary to correctly adjust the rate of fluid flow through the sand trap so that the particles have time to settle to the bottom.

Placement of treatment facilities

For treatment plants, even areas with a low groundwater level are suitable so that the liquid can undergo final treatment in the soil. In private homes, this is a plot hidden from prying eyes. It is desirable that odors, sometimes appearing during the decomposition of organics, do not reach the neighbors.

Typically, equipment is selected based on the characteristics of the site and the type of soil. For example, on loamy technical effluents are poorly absorbed, stagnation can occur. Therefore, drainage communications are mounted that remove liquid from the site through pipes.

According to sanitary requirements, the sewer tank should be at least 50 meters away from the drinking well. There are filtration fields around the filtration well, in the radius of which wells designed for drinking water are not laid.

It is necessary to observe a distance from the edge of the road - at least 3 meters. If there is a laid electric cable, the sewer is removed from it by 1 meter. From the gas pipeline - by 1.5 meters.