Drainage pipes, also called drains, are designed to remove excess moisture from the soil. Creating pipe-based drainage is most practical. All elements are buried in the ground, they take water from the soil, while not spoiling the landscape.

Principle of operation

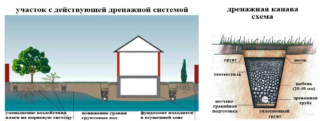

According to the intended purpose, pipe products for drainage are divided into two types - for collecting moisture and for removing it. The collecting elements are equipped with perforations. Holes are created in the pipe body along the entire circumference or in one of the sectors through which moisture enters the mains. Such communications are installed at an angle around the drained territory or on its entire area. Usually they are put up near buildings, otherwise excess water can destroy the foundation of the structure and cause mold to form on the walls. Excess moisture goes to the well facilities.

According to the intended purpose, pipe products for drainage are divided into two types - for collecting moisture and for removing it. The collecting elements are equipped with perforations. Holes are created in the pipe body along the entire circumference or in one of the sectors through which moisture enters the mains. Such communications are installed at an angle around the drained territory or on its entire area. Usually they are put up near buildings, otherwise excess water can destroy the foundation of the structure and cause mold to form on the walls. Excess moisture goes to the well facilities.

Products for abstraction are devoid of perforations. They have a different working principle. They are needed to empty drainage tanks. Water flows into collector devices or specially equipped ditches. A characteristic feature of such highways is that they can be buried in the ground by more than 10 m.

Pipes are also often laid in storm ditches by the road, connecting them to a common drainage system. This will ensure a comfortable journey of vehicles.

A variant of moisture-collecting products are models with a filtering effect due to winding with coconut fiber or geotextiles. Filters do not allow suspension, preventing the formation of plaque, which increases the life of the entire system. This is especially important in clay areas where groundwater contains many impurities.

Types and design features of drainage pipes

Draining products are classified by price and design characteristics. But first of all, it is necessary to pay attention to the material of production.

- Asbestos cement. Most often, pipes are made with cuts from above to get moisture inside. These holes are staggered.

- Ceramics. Clay pipes come with perforations, crevices and grooves on the outside for better absorption of moisture.

- Expanded clay and plastobeton. These are porous building materials that absorb moisture well. Perforation products do not need.

- Plastic. Pipes are made of polyethylene compositions of high or low pressure (LDPE or HDPE), as well as PVC.

The lowest price is asbestos cement products. They take moisture well, but are not very popular, since it is believed that the material is harmful. In the west, it is banned for use. A variety of asbestos structures are chrysotile cement products. This type of asbestos of a white shade is environmentally friendly and does not harm health. In such models do not make cuts, since the material is porous.

The most popular are pipes made of polyvinyl chloride plastic and polyethylene. The former usually do not perforate; they are used to remove moisture. They look like sewer pipes. They are pretty cheap. The latter often corrugate and equip with moisture-absorbing holes. Such products are flexible, but durable, they can be laid on a site with any landscape. Outwardly, they look like large irrigation hoses.

Pipes from polymeric materials are made of two types: single-layer or double-layer. The number of layers is selected depending on the density of the soil.

Filtering material can be purchased separately, but it is much more convenient to immediately purchase products in geotextile cases.They are completely ready for immersion in the ground; they are used both on loamy soils and on marshy soils to drain them.

Filtering material can be purchased separately, but it is much more convenient to immediately purchase products in geotextile cases.They are completely ready for immersion in the ground; they are used both on loamy soils and on marshy soils to drain them.

The most resistant to external influences products are Softrok systems. First, the pipe segments are covered with polystyrene filler, and on top they are wrapped with a geotextile mesh. This design prevents the suspension of suspended matter inside its pipeline and its freezing, increases the efficiency of the drainage system by 40 percent. Thanks to the complete readiness of the systems for laying, the laboriousness of the work during the arrangement of the drainage system is reduced.

Flat drain pipes are conquering the market. They are also called “panel”. They are somewhat similar to fire hoses. Produce similar products with perforation and in a filtration shell made of geotissue. Rectangular products have increased compressive strength, so drainage can be equipped almost at the surface. This contributes to savings in earthmoving operations. Thanks to compact folding, flat models take up minimal space during transportation. Such a drainage pipe works no worse than a round analog.

Simple drainage pipes are sometimes used for drainage work. They are perforated with their own hands and installed as moisture-collecting drains.

Size range

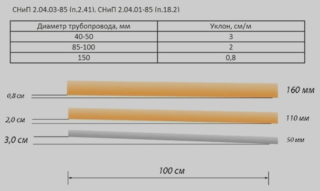

According to GOST, drainage pipelines are produced in segments of 6 or 12 meters. Flexible options can be longer, they are twisted into bays. Products are distinguished by diameter - 110, 160, 200 mm.

For systems with a high load, pipes with a large cross-section are produced - up to 300 mm.

On a small area with low groundwater, you can install products with a minimum diameter. But if the drainage consists of many branches, even in a small area you will have to use both large and small sections of the pipeline.

Criterias of choice

The main criteria for selecting drainage system elements are the stiffness and location of the perforations.

The first characteristic depends on how deep the pipes are laid. They must not deform under a heavy layer of soil. When purchasing pipe segments, look at the marking, which indicates the stiffness class:

- SN 2–4 are installed to a depth of 3 m;

- SN 6 - up to 4 m;

- SN 8 - up to 10 m.

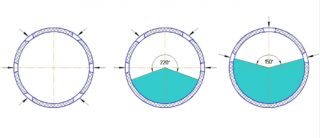

The depth of groundwater, the amount of precipitation and the method of installing the drainage line are important. These data are taken into account when selecting a perforation pattern. If the holes are made along the entire circumference of the pipe, it is suitable for reducing the level of subsoil sources, draining drains after rains and snowfalls.

For "stormwater" choose pipe segments with holes in 1/3 or 2/3 of the circumference. Half-circle perforated pipes are used for universal sewers.

The choice of pipeline elements also determines their cost. For an average meter of a perforated pipe with a cross-section of 110 mm in the geo-fabric filter, on average, you will have to pay 55 rubles, 160 mm - 110 rubles and 200 mm - 185 rubles. For panel models, the cost per linear meter starts from 75 rubles.

The price of smooth non-perforated drainage pipes for groundwater drainage is lower - it starts at 12 rubles per meter. The highest cost for a large diameter drainage pipe (over 200 mm) in a filter made of coconut bark - from 1000 rubles per meter.

Among Russian manufacturers, the greatest demand is for the brands Ruvinil, Nashorn, Politek, KamaPolymer. Among foreign brands, Polieco, Wavin, Uponor, Rehau are popular.

Laying rules

Carrying out the highway is carried out at an angle to the catchment. If the territory is flat, the slope is created with your own hands. The installation depth of the pipeline is determined depending on the location of underground sources, but not less than half a meter.

Carrying out the highway is carried out at an angle to the catchment. If the territory is flat, the slope is created with your own hands. The installation depth of the pipeline is determined depending on the location of underground sources, but not less than half a meter.

The distance between the drainage lines during their installation is determined by the amount of water in the territory: the more it is, the closer the pipelines are.

Also decide on the location of the inspection hatches needed to check and remove possible blockages. They must be installed in the corners of the turns of the highway.

Before installation, be sure to create a project with a drawing in scale. This allows you to calculate how many and what section and pipe stiffness is required for the drainage network device.

Stages of laying a drainage pipeline:

- A trench is dug to a depth of not less than half a meter and a width exceeding the cross section of the pipeline by 50 cm.

- A sand cushion 10 cm thick is poured at the bottom.

- On top of the sand gravel is poured with a layer of 10–20 cm.

- Pipe sections are laid, connecting with each other and with audit wells.

Burial occurs in the reverse order: a layer of crushed stone, a sand cushion, a layer of soil.

At the final stage, the pipeline is withdrawn from the boundaries of the site and its connection to the catchment. If it is necessary to increase the throughput of the drainage line, a system assembled from several pipes of different sections is laid in a trench.

Pipe drain installation errors

Poor line operation can be caused by the following reasons:

Poor line operation can be caused by the following reasons:

- Drains are at a great distance from each other. Systems are installed with a distance of not more than 10 m for clay areas and 50 m for sand.

- Incorrect trench depth. Such a mistake can lead to water imbalance, which will cause stagnation of moisture in the area. Shallow depths cause ice plugs, which will lead to flooding of the territory in early spring. The pipeline may be higher than the water level and it will not be able to get into the drainage system.

- Failure to tilt. If the line is installed strictly horizontally and there is no bias towards the catchment, moisture will stagnate in the pipeline.

- A large number of revisions. The distance between inspection hatches must be greater than 50 m, otherwise they will interfere with the normal operation of the system.

A typical mistake is an attempt to save on the use of non-design pipes for the line, which leads to malfunctions and a significant reduction in the life of the system. This applies both to the cross-section of the pipes and to the material of production.

Rules of operation and maintenance

The drainage pipeline requires a systematic check for mud accumulations inside and cleaning as necessary. To do this, revision wells are mounted in the system. Inspection must be performed at least once in 12 months. After heavy rains, flooding and floods, an unscheduled drain check is required.

The fact that pipes need to be cleaned can be reported by stagnation of water in the inspection well. Settling of mud, silt, sand also occurs.

Scheduled cleaning of the highway is performed every 3 years with the correct arrangement of the system and equipped with the necessary filters. Otherwise, cleaning is carried out as it becomes dirty. Drain cleansing is performed in two ways: mechanical and hydrodynamic.

The first option involves crushing solid contaminants and mechanical extraction of dirt using a pneumatic installation. In the second method, the line is flushed with water and air under pressure using a compressor and pump. This option is more costly, but more reliable.

There is nothing complicated in the drainage device. If everything is done technologically correct and according to the project, a self-laid system will last more than half a century.