High-quality sewage treatment allows you to get 98% purified water at the outlet. In the future, it can be used for farming (watering, irrigation). In private ownership, an autonomous wastewater treatment plant for cottage and other individual buildings is in demand. At industrial facilities, these are entire stations operating in a continuous mode.

Definition and principle of operation of VOCs

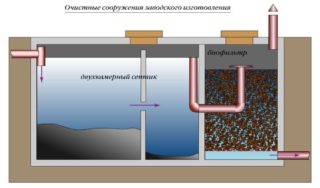

VOC (local wastewater treatment plant) is a sewer system designed to clarify wastewater: domestic, industrial, household. The autonomous private station has a compact design in the form of a two-three-chamber tank. As a rule, it is not connected to the city collector. Industrial treatment facilities are already presented in the form of a powerful system consisting of several workshops connected to the communal main.

VOC (local wastewater treatment plant) is a sewer system designed to clarify wastewater: domestic, industrial, household. The autonomous private station has a compact design in the form of a two-three-chamber tank. As a rule, it is not connected to the city collector. Industrial treatment facilities are already presented in the form of a powerful system consisting of several workshops connected to the communal main.

The principle of operation of all VOCs in the first stages is almost the same:

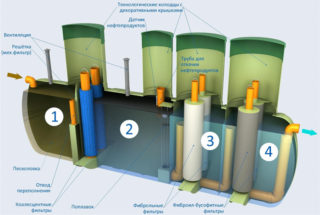

- Mechanical wastewater treatment. Primary dirty water is freed from large suspensions and household waste, feces. All of them settle to the bottom or rise to the surface in special settlers (depending on the weight of impurities).

- Wastewater freed from large debris is sent to a second tank, where grease traps are included in the work. They free water from films of oil, oily substances.

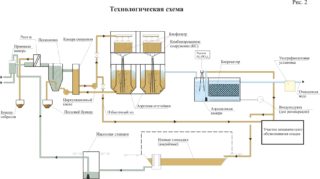

- Sewage purified from large suspensions and fats is called “gray effluents”. At this stage, they are treated with bacteria that turn residual debris into sludge and produce clarified water at the outlet. In local treatment facilities for industrial enterprises, it is possible to achieve almost 100% clarification of effluents. It is important to remember that in winter, at low temperatures, the speed of bacteria is seriously reduced. In this case, volatile aerotanks are selected and connected to business.

- Purified industrial waters are subjected to additional processing with chemicals according to the developed scheme. This is done to finally neutralize impurities in the form of undissolved particles of garbage, fat decay products, etc. Most often, flotators, coagulants are used in industrial VOCs.

As a rule, in household septic tanks, the first two or three stages of wastewater treatment are more often used. Subsequently, clarified water drains into the ground. When installing a home VOC, it is necessary to calculate the volume of effluents. It is equal to 200 liters of water per 1 family member per month.

Advantages and disadvantages of VOCs

All treatment facilities due to their device are distinguished by such advantages:

All treatment facilities due to their device are distinguished by such advantages:

- Absolute environmental friendliness. According to the law of the Russian Federation, the discharge of industrial / household waste and sewage into water bodies, soil is prohibited. This is a criminal and administrative offense. With the help of VOCs, it is possible to bring polluted water into a state acceptable for the discharge of effluents.

- Lack of a specific smell on a private site (only for own households).

- Relative ease of installation. It is enough to prepare the pit and mount the tanks.

- Durability. If you install plastic tanks or volatile aeration tanks in the ground, they last 50 years or more.

- Saving the family budget on the services of a cesspool worker. A home septic tank can be cleaned no more than once every six months or a year.

The relative disadvantages include the volatility of aeration tanks and the need for the cost of acquiring an autonomous structure. But they pay off already in the first or second year of operation of VOCs.

Types of designs

During the construction of local wastewater treatment plants, one of the following types is taken as the basis:

During the construction of local wastewater treatment plants, one of the following types is taken as the basis:

- Standard cesspool.It is a reservoir formed in the ground and lined with bricks from the inside. In an improved version, a plastic container for collecting wastewater is installed in the pit. In the future, they are used for pumping out a sewer. This is the main drawback of the cesspool in addition to soil contamination in the absence of a sealed bottom.

- Septic tank. A special design of two or three chambers in which stage-by-stage sewage treatment takes place.

- VOC. Local treatment system powered by electricity. It has a multi-stage system for clarification and filtration of effluents.

The last option is the most environmentally friendly. At the output, water clarified by 98-100% is obtained, suitable for safe discharge into the environment or for further use on the farm.

Varieties of treatment systems

There are three types of local treatment systems:

- Industrial. They are huge stations, consisting of several workshops. Designed for wastewater treatment from factories, manufacturing enterprises, pharmaceutical / chemical complexes.

- Domestic municipal sewage VOC. Connected to a common highway and more often located outside the village. Such facilities also have impressive dimensions and are serviced by whole shifts of workers.

- Household. Standard septic tank for private use. It is used if there is no possibility to connect to the city sewage system.

For living conditions, pre-made septic tanks made of plastic are more often purchased. However, there are also such homeowners who prefer to independently mount receiver tanks made of concrete, brick, car tires.

VOCs for industrial enterprises

Industrial wastewater treatment systems are impressive in size and often consist of several huge workshops. In each of them there are separate stages of purification of contaminated effluents with special chemicals, reagents. The need for such processing lies in the fact that industrial waters contain more aggressive suspensions and impurities. Accordingly, the same aggressive reagents are used to clean such effluents. With their help, it is possible to purify dirty water from such enterprises:

- creameries and meat processing plants;

- chemical and pharmaceutical industries;

- Breweries and canneries;

- poultry farms;

- glass, automobile factories, etc.

Each of the cleaning steps takes place in a special separate pool. This allows you to control the effectiveness of the process.

Most industrial VOCs use the UV method as the final stage of disinfection of clarified water instead of the usual chlorine - ultraviolet treatment of light effluents.

VOC for storm water

Rain and snow water require no less thorough cleaning before being discharged into the ground and water bodies. Stormwater runoff contains chemical impurities in the form of dissolved reagents (used for paved roads in winter in icy conditions), the inclusion of household chemicals and automobile oils discharged from car wash buildings, car services, etc. In addition, sand and soil are also contained in rainwater, which also previously removed from drains.

Structurally, the atmospheric water purification system looks like this:

- a storm water inlet in the form of a special tank with an upper grill;

- trays and gutters in the form of an extended collector;

- sewage receiver, it is also a sump.

In the sump, thereafter, storm water is treated. Later they are dumped into the ground or ponds.

VOCs for the treatment of storm drains must be equipped with special sand traps and gratings. They help prevent large debris, particles of sand and soil from entering the collector.

Prices for autonomous VOCs

The cost of industrial treatment facilities amounts to millions of rubles. Private sewage treatment prices:

| VOC name | Production material | Dimensions (m)

LxWxH |

Number of people served | Price, rub.) |

| Tver-0.75 P | Polypropylene | 2.25x0.85x1.76 | 3 | 69 800 |

| Tver 1P | Polypropylene | 2.5x1.1x1.67 | 5 | 88 000 |

| Tver 2P | Polypropylene | 4x1.3x1.67 | 10 | 131 000 |

| Tver 3P | Polypropylene | 4x1.6x1.67 | 15 | 151 000 |

| Tver 6P | Polypropylene | 4x1.6x1.67 | 20-30 | 300 000 |

The prices of mini-treatment facilities for the house may vary depending on the region and the manufacturer of the system, but on average they correspond to those indicated in the table.