Every farmer has to deal with the need to resolve issues related to the disposal of animal waste products, regardless of his status. Considerable investments are required to load, take out and bury waste. There is an effective and relative solution to turn excrement into money. Processing manure into biogas is a technology that has long been used in developed countries.

General information about biogas

Manure contains many nutrients and minerals. In small quantities, it can be implemented in a small farm, where there are beds and gardens. For medium and large farmers, waste management is a real headache. The accumulating heaps emit an unbearable smell, are sources of infection, their contents gradually lose their beneficial properties.

Manure biogas has almost the same composition as natural gas, which is used in municipal systems. The formation of combustible volatile compounds occurs due to the activity of anaerobic bacteria, for which organic raw materials are a food source. The substance they emit consists of 70% methane and 30% carbon dioxide. The first component is lighter than air, the second is heavier, which contributes to their natural separation without the use of mechanics and electronics. It remains to collect gas from manure and send it to consumers.

The benefits of biofuel production at home do not end there. In the bunker there remains a high-quality fertilizer saturated with phosphorus and nitrogen, which has lost most of the pathogenic microorganisms that died in the absence of oxygen. The resulting gas in its properties is practically not inferior to natural analogues. According to the degree of heat transfer, 1 m³ is comparable to 1.5 kg of coal.

Conditions for the formation of gas from manure

Combustible is a waste product of billions of bacteria that process organic residues produced by domestic animals and birds. For this process to occur intensively and continuously, appropriate conditions must be created. Natural methane was formed in the bowels of the earth, in an area with a warm climate.

To get gas from manure, you need the following:

- Sealed tank. Oxygen in the air inhibits anaerobic bacteria. Because of this, their activity decreases, the production of combustible compounds decreases to a minimum. In addition, the presence of oxygen contributes to the development of pathogens harmful and dangerous to human health. We should not forget about the specific aromas that produce feces.

- Temperature mode. Bacteria participating in the process of manure decomposition are activated and feel great at a temperature of + 30-50 ºС. To achieve this, it will be necessary to create reliable and effective thermal insulation for the tank with manure.

- Equipment for the collection, storage and transportation of extracted raw materials to the house. The installation of the desired type can be bought or made independently from improvised materials. The second method is cheaper, but requires more time and effort.

With the right approach to business, it is easy to get up to 4 liters of biofuel per 1 liter of usable capacity.

Technology for producing biogas from manure

The extraction of gas from waste and its subsequent use as fuel allows saving on utilities and reducing the burden on the environment. With a large amount of raw materials obtained, it can be used to heat water and generate electricity.

As a raw material for the production of methane at home, feces of birds, fur animals, small, medium and large livestock are used. It is allowed to include tops, sawdust, grass, foliage, animal fats and offal remaining after slaughter in the mixture.

Getting fuel is as follows:

- The creation of a design that, in its structure, resembles the place where anaerobic bacteria live - the stomach. It is warm, dark and free of oxygen.

- Preparation of a mixture for fermentation. It should be 90% water without chlorine. The solution is poured and the fermentation process begins almost immediately. Under well-created conditions, it lasts about 12 days.

- The spent material is pumped out, a new one is poured instead. It is not necessary to plant fresh bacteria, as they are already in the litter.

- Drainage of biogas. It contains a large amount of moisture, if the product is not processed, it will not burn.

- Collection of fuel received. For this, tanks, barrels, plastic tanks or plastic bags are used.

Gas production plants can be individual, for one house, or common, supplying fuel to several livestock farming farms.

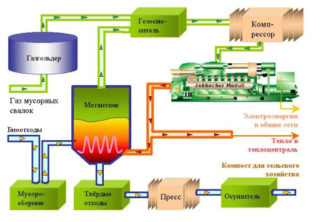

Basic installation diagram

To get biomethane from manure, you need to create an effective installation in which the fermentation process caused by the activity of anaerobic bacteria will intensively and continuously occur. To process raw materials throughout the year, regardless of air temperature, you should consider a heating system.

A standard basic installation consists of the following parts:

- Bioreactor It is a tank with a capacity of 5-50 m³. The product has an inspection hatch, openings for supplying raw materials, fertilizer output and outflow of fermentation products. A device is also installed in the tank for mixing biomass of forced or natural action. The tank is finished with heat-insulating material to protect it from the cold.

- Loading container. Manure and other raw materials are dumped into it. After mixing with water, the substance is pumped into the reactor by a pump.

- Fertilizer collecting tank. It receives waste material rich in minerals and nutrients.

- Heating system. To maintain the desired temperature, a separate heater is installed under the tank or pipes from the boiler running on biogas are launched along its perimeter.

- Pipeline. It puts a filter, valve, dryer and compressor. These structures take part of the substances released from manure, but the quality of the gas is significantly improved.

- Gas holder. Located at the highest point of the structure. Designed for the collection and storage of the finished product. Storage capacity corresponds to the estimated volume of gas produced. If the tank is metallic, the gas is contained in it under a pressure of up to 12 atmospheres.

Some plant models are equipped with a control panel. This slightly increases the cost of the product, but fully automates the process of biogas production. The controller maintains the desired temperature, mixes the raw materials, removes gas, loads the manure and pumps out the waste material.

Getting gas from manure at home

For the construction of a plant for the production of gas from manure, there is no need to coordinate their plans with any authorities. This structure is a closed type and does not pose a threat of pollution of the soil, atmosphere and groundwater.

The construction of the bioreactor is carried out in the following sequence:

- Determining the location and size of the installation. Drawing up the scheme.

- Making or buying a finished tank. As an option for a small site - the construction of an underground tank made of reinforced concrete.

- Drilling holes for pipes, installation of gaskets.

- Installing a tank for manure and fertilizer.

- Laying of communications (supply and output pipe, heating circuit).

- Installation of a cylinder for collecting biogas. Arrangement of the connecting channel with a compressor, filter and water seal.

- Supply of water and electricity.

- Thermal insulation and decoration, cleaning the territory.

The mass must be constantly mixed so that it is homogeneous. This can be done manually or using an electric motor. A mixer is used, mounted on the upper wall of the reactor.

Extraction and use of biogas provides farmers with many benefits. The technology allows you to get a large amount of free fuel for heating all buildings and high-quality organic fertilizers. With proper organization, the process of obtaining gas from the litter can be brought into a separate profitable production. Do not forget about the environment. Burning gas is much safer than coal, fuel oil and firewood.