A standard dielectric gas insert is installed in gas piping systems to prevent stray current. The structure of the element, its purpose and principle of operation should be known to every user, since the safety of all gas-powered equipment depends on it.

Dielectric insert for gas

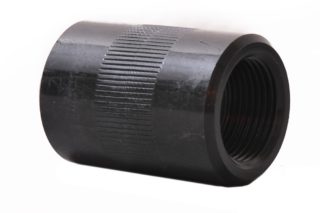

The dielectric coupling or insert for gas is a cut-off type fitting, which is placed on the element between the tap and the supply part to the gas unit. This element is divided into two categories, taking into account its appearance and installation method. Simple inserts are mounted between the gas device and a hose suitable for a particular system; more modern bushings are mounted at the joints of the pipe parts.

Such couplings vary in size, taking into account the diameter of the thread, most often used parts with numbers 1/2, 3/4 and 1. The presence of several options for the element allows you to select the product for a specific size of a flexible type bellows eyeliner. The thread at the coupling may be internal or external. The bushings and inserts have identical parameters regarding strength and can withstand pressure up to 6 atmospheres.

Most often, the insulating insert on any gas pipeline is made of polyamide, this material belongs to the category of non-combustible polymers, its resistance varies within 5 million Ohms.

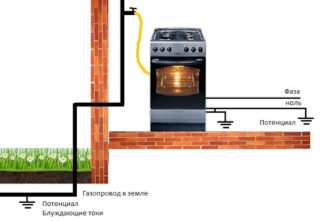

Causes of leakage currents

Wandering currents are usually formed underground due to impulsive breakdowns of household or factory lines from power lines. In such cases, the source of voltage is the ground loop, railway or tram tracks. A current of this type enters the gas pipeline system because of the differences between the resistance of the soil and metal particles from the main for fuel delivery. As a result, the entire amount of electricity that has fallen into the soil does not go inside it, but passes into metal elements or bare wires. Current can form inside the system at any time, since most domestic or public gas pipelines are made of metal.

Often, the main pipe becomes the cause of stray voltage. To protect the pipeline from rust, it is loaded with electricity potential with little force. It blocks the process of electrochemical separation inside structural materials. If a dielectric coupling for gas is damaged in a single insulator, a good protection potential turns into excess current. In addition, this voltage can occur due to poor grounding of the circulation pumps or other parts that make contact with the wiring of the heating system or the home branch of the pipeline.

A dielectric for gas flows can eliminate serious problems and increase the safety level of everyone who uses gas equipment that is connected to a common system.

Application and functions of dielectric inserts

The gas dielectric coupling is a mandatory element, the presence of which is provided for by the rules governing the construction of gas distribution systems SP 42-101-2003.It should be present in pipelines of any type, including options with polyethylene pipes. If such a clutch is missing, the stove, column or other electrical devices can fail at any time after the appearance of stray current or cause it. Sparks may occur inside the pipeline and cause a fire. Cases of self-ignition of wiring occur quite often and can cause a large accident.

The process of detonation of a gas-air mixture may well destroy a multi-story building when a fire is not detected on time. If stray current appears inside the pipes due to an emergency or during a thunderstorm, the risk of serious injury to electrical equipment owners increases significantly. The dielectric coupling for each gas pipe should be in any building or apartment where gas-powered appliances connected to electricity are operated. In addition to its main functions, it prevents the formation of stray currents that arise due to problems during the installation of boilers, columns or gas stoves.

Types of dielectric inserts for gas

The dielectric for a gas hose according to the product range of elements for gas distribution devices is divided into two standard categories. These are isolation cranes, couplings, barrels or barrels, as well as standard bushings. The choice of a specific type depends on the installation conditions and the characteristics of a particular system.

Insulating couplings

Couplings are divided into three categories, which differ from each other mainly by a threaded diameter, its value can be 15, 20 or 25 mm. Separation by this criterion makes it possible to mount inserts in any pipelines, since diameters less than 1/2 and more than 1/4 are not used in the Russian gas pipeline system. Sub-types of inserts, the so-called barrels, can have an external thread on both elements or an internal and external thread on each.

Dielectric bushings

Such inserts are inserts that prevent the passage of electric current. They are placed between the pipes with gas and wiring, the diameter of such elements varies between 8-27 mm, both sides are supplemented with thread from the inside. The bushings are not inferior to the couplings in terms of resistance and tensile strengths, parts can withstand pressure up to 493 atmospheres.

Correct installation

An insulating sleeve or gas insert must be inserted between the gas valve and the bellows or other type of inlet. It is necessary to install the element taking into account safety requirements, before starting installation it will be necessary to shut off the tap without fail and do not open it until all necessary steps have been taken to eliminate possible leaks. Installation must be carried out by gas service personnel with appropriate qualifications and approval for this type of work. During installation you will need:

- Prepare a pair of adjustable wrenches, one of them is designed to hold the housing from the valve, the second one needs to twist the nut from the eyeliner connecting the tube to the device running on gas fuel.

- Install any type of gasket on the ends of the insert, for example, polymer, then manually put the dielectric inside the gas pipeline.

- While holding the valve with one key, tighten the second coupling or sleeve until it stops; during installation, care must be taken not to accidentally break the threaded coating and damage the element case.

- Screw the nut from the bellows hose to the other part of the coupling, while holding the insert with an adjustable wrench, then tighten the connecting parts as tightly as possible.

When a standard gas insulator is installed, you will need to check the docking areas for leaks.For this purpose, use a small brush or brush, which is carefully soaped. Soap solution must be applied to each inlet, as well as the joint, then slowly open the gas supply tap. If there is foam or bubbles, the valve is closed and the joints are inspected again. It is possible to use the gas unit only after bubbles no longer form in the solution. In no case should they be checked for leaks using matches or a lighter; if there is a leak, a fire can cause a gas explosion.

Installation of gas units and additional components is carried out with particular accuracy, since the safety of residents of the building directly depends on the correct connection of the parts. Hoses are mounted according to the principle of open installation, hoses should not be hidden or covered with furniture or household appliances, the element itself, as well as the dielectric sleeve or the gas coupling, must be mounted from the outside. To connect the equipment do not use too long or shortened hoses, since due to pressure this part may become shorter, in addition, it is forbidden to stretch it. The sleeve may sag after docking with the pipe, but its twists and bends must not be allowed.

When installing a dielectric adapter for household gas, you need to make sure that steam or water that can provoke the oxidation of metal parts does not get on the hose. Cooking surfaces are set aside from the gas pipe, in the presence of atypical threads in the stoves and other equipment, adapters are used to connect.

It is not necessary to interconnect various materials, for example, steel and copper. You also need to monitor the pressure on the element while tightening the joints so as not to spoil or tear the threaded coating. To ensure a more snug fit, you must use FUM tape.

Popular manufacturers

You can choose the right insulator designed for gas supply among dielectrics of Russian or foreign production.

The most popular are parts from the Turkish brand Tuboflex, this company offers couplings and bushings with various types of threads and at an affordable cost.

Inserts from the Italian manufacturer UDI-GAS, which offers innovative couplings equipped with additional protective layers, have earned a good reputation.