The standard gas ball valve is one of the most reliable locking mechanisms in comparison with analogues of other types. Such cranes are divided into several varieties and have their own characteristics, which must be taken into account during installation and operation.

The device and features of the ball valve for gas

The domestic gas faucet can be used for internal systems and for external highways; most often, elements with a diameter of 2 to 12 inches are used. Spherical mechanisms are necessary for the complete closure or opening of the gas flow, their main feature is the shut-off design. It has the shape of a ball with a special through hole, which corresponds to the diameter of the pipeline. If necessary, shut off the fuel supply, the valve is turned 90 degrees so that it is perpendicular to the pipe.

The part control process is carried out with the help of a lever supplemented with hermetic rings. Ball valves have many advantages, including good tightness and high insulating properties. Modern cranes are lightweight due to the use of special metals and alloys, are characterized by increased reliability and can be used for 10 years without malfunctions.

Types of gas taps

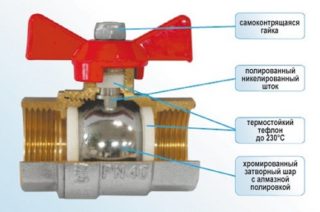

There are various ball valves for household gas, differing from each other in design and appearance. All products consist of a standard set of parts:

- case made of steel, brass or nickel;

- a piece for connecting the pipe;

- throat part for stock;

- a connecting rod that provides communication between the movable mechanism and the handle;

- locking ball for blocking gas.

Additionally, the ball is reinforced with a special seat, preventing its displacement, and is held in it by means of a ring. The seal, flange and springs are responsible for the tightness and connection of parts of the entire structure.

The main part of the device is the handle, with the help of which the locking mechanism is controlled. It is fixed in one place with a strong nut and is supplemented with a stopper that limits its progress.

Ball

Cranes for apartments, houses, office premises and enterprises can be made of brass or nickel. Elements of the first type are distinguished by good tight properties, do not cause difficulties during operation and are suitable for water pipes. Their nickel counterparts can be full bore and reduced, taking into account bandwidth. The most common are cranes with external and internal thread, welded, flanged and threaded type.

Angular

The corner gas valve is equipped with inlet and outlet nozzles located at an angle of 90 degrees towards each other. This structure allows you to use the element when assembling nodes in hard-to-reach places, as well as in areas where bending of the trunk is required.

Threaded

Threaded or coupling parts have a small diameter, most often they are used for domestic gas pipelines. They are connected to the pipeline by means of a thread connection, thanks to which they got their name.

Flange

Flanged taps are designed for outdoor large diameter gas pipelines. The connection in them is carried out by the flange method using bolts.Such elements are collapsible, which makes it possible to dismantle them and then re-install in other areas.

Welded

Elements with a welded structure are also used for external gas pipelines, the diameter of such taps ranges from 10-70 mm. They are connected to the pipes by welding, so in the future these sections of installation will be non-separable. The list of pluses of elements includes optimal tightness and a high level of reliability; in addition, welded fittings do not require additional maintenance.

- Threaded

- Weldable

- Flange

- Angular

Differences from water fittings

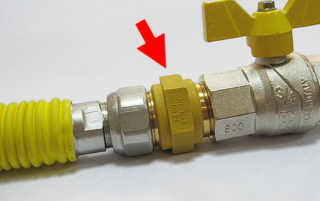

The gas valve differs from the water tap in the appearance of the lever, which has a yellow color instead of red, as well as a number of design features:

- long connecting thread;

- more durable housing and locking mechanism;

- ability to withstand high pressure;

- the presence of strong and tight rings.

Despite the fact that a gas standard faucet is more expensive, it cannot be replaced by water fittings, since such savings can cause the replacement of the main elements of the system as a result of an accident.

Application features

In most cases, ball valves are installed in places where gas equipment is used, for example, in the kitchen, and a separate valve is needed for each source of fuel consumption. Shutoff valves can be used to shut off the flow and to control it, for example, a three-way valve makes it possible to direct the flow from one pipeline to the next.

The faucet for a standard gas pipe in the kitchen must match the features of the system and the type of equipment. Most often, threaded elements are installed in such rooms, which do not cause problems during installation and throughout the entire life cycle.

Features of gas valve replacement

Ball valves of any type are not insured against breakage, therefore, if a malfunction is detected, the element must be urgently replaced. It is better to entrust this work to gas service specialists. They acquire a new crane, focusing on the diameter of the gas pipeline, which must exactly match it.

Before the expert arrives, you need to light the gas on the stove and close the valve, directing the burner and waiting for it to completely die out to allow the remaining fuel to exit the gas pipeline. After completion of work, the specialist must necessarily test the check valves for leaks and enter information on the replacement of the element in the technical data sheet.

Terms of Use

In order for the household gas ball valve to last as long as possible, standard recommendations must be followed during its maintenance. The element is designed to quickly shut off the gas flow inside the pipeline. You can open and close it only with the help of the factory handle; for this purpose it is forbidden to use any tools.

The design of the crane itself is not intended for flow control; the element has only two working positions: open and closed. If it is half open, the fast flow of the pumped fuel can cause deformation of the sealing rings, as a result of which the valve will quickly become unusable and will have to be changed. The element must not be used in environments with contamination that could lead to mechanical damage to the gaskets. Sometimes the fastenings of the rotary handles are weakened, in such cases it is necessary to tighten the screws securing them. In the presence of leaks of stuffing box gaskets of the rods, the nuts located under the valve handles are adjusted.

According to the instructions from the crane manufacturers, any repair work, including the replacement of the device, is forbidden to carry out independently in the absence of the necessary skills.

Household gas taps manufacturers

When choosing valves, you need to pay attention to all the details and purchase only high-quality products from well-known manufacturers. Products of the Italian companies FIV, Valtec and Bugatti have proven themselves best. The devices of German brands Dungs and Profactor, Polish brands Broen Ballomax and Efar, as well as the Russian concern LD are also of good quality.

It is not recommended to save and give preference to Chinese manufacturers, since such fittings do not meet international standards and requirements.