Pipes made of metal have an extensive list of uses, including electrical work. Wiring in metal pipes is not afraid of mechanical, chemical effects, which is a big advantage. During installation, it is important to comply with work technology and fire protection requirements.

Materials for the manufacture of metal pipes for electrical wiring

The choice of material from which the pipe is made will depend on the type and design features of the room where the work is planned.

Pipes for electrical wiring are made of steel, brass, copper, plastic.

Features of brass and copper pipes

Despite the large number of advantages, copper pipes intended for wiring are not in demand. This is due to the high cost.

The following characteristics are characteristic of brass and copper pipes:

- Compared to steel, these two materials are less susceptible to the negative effects of corrosion.

- Polished and neatly mounted channels in an open way can serve as a decoration of the design of the room.

- Due to the wide range of fittings and good ductility, installation can be done independently.

It is worth noting the durability of the structures, as well as high resistance to negative environmental influences.

Brass and copper thin-walled structures are optimal for installation on the surface of walls and ceilings. Also can be used when arranging hidden wiring.

Steel pipe specifications

Steel electrical pipe for cable laying has a significant drawback - a large mass, but the material is highly durable, which is an advantage. This type of pipe is recommended to be purchased if the wiring is to be laid in wooden houses. It is also worthwhile to take care of grounding, since steel is a good conductor, otherwise, proper safety will not be provided in the building structure.

Ordinary pipes made of steel have a wall thickness of more than 0.25 cm. For thin-walled steel structures, this figure ranges from 0.16-0.25 cm. It is forbidden to use such products if the surface of the aluminum wire is exposed.

The installation of thick-walled channels is characterized by the need for welding and high cost. The cost of the material itself is relatively low, but high strength is noted.

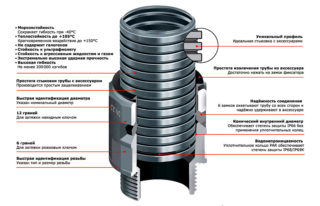

Types of metal pipes

Metal pipes are classified by design features:

- direct;

- corrugated.

Given the characteristics of each variety, it will be possible to choose the most suitable option, sometimes even saving the family budget. Criteria for choosing pipes for wiring:

- plastic,

- diameter,

- weight,

- density indicators

- length.

When choosing metal pipes for electrical wiring, it is important to correctly correlate the technical characteristics and cost of the goods. The pricing policy is diverse, but quality products cannot cost too cheap.

GOST Standards

A seamless metal pipe designed for electrical wiring is regulated according to GOST document No. 8732-78. The main indicator for their pricing is weight. Also in GOST there is a table that helps to correctly correlate the size of the wall and the volume.

| Wall thickness mm

Common |

Wall thickness mm

Lungs |

Outer diameter mm | Nominal diameter Dy, mm |

| 2,8 | 2,35 | 26,8 | 20 |

| 3,2 | 2,8 | 33,5 | 25 |

| 3,5 | 3,0 | 48,0 | 40 |

| 3,5 | 3,0 | 60,0 | 50 |

| 4,0 | 3,2 | 75,5 | 65 |

| 4,0 | 3,5 | 88,5 | 80 |

| 4,0 | 3,5 | 101,3 | 90 |

| 4,5 | 4,0 | 114,0 | 100 |

During the construction phase, it is important to ensure good insulation, otherwise serious problems may arise.

Advantages of metal pipes

To understand why, due to the large number of analogues at a more affordable cost, metal structures do not lose their relevance, you need to familiarize yourself with their main advantages:

- Even in flammable building structures, wires are reliably protected from fire by a corrugated metal hose.

- Thanks to the flexibility of stainless steel corrugation, you can give any shape without the use of additional tools.

- During the operational period, the cable channels do not require maintenance and any preventive measures.

A large arsenal of tools is not required for installation.

Rules for installation work

At the stage of installing pipes for electrical wiring, it is important to observe the following rules:

- The work should be carried out in 2 stages. First, the beginning and end of pipes that are connected to the distribution panel, control device, and power receiver are schematically depicted. Next, suitable mounting points, bending angles, as well as places for mounting boxes are calculated.

- When installing metal conductors, the wires must be earthed with a flexible copper jumper leading from the body to the pipe. Alternatively, grounding nuts may be used.

- Before tightening the pipe, it is important to purge, then straighten.

- In the boxes you must always leave a margin for connection in case of emergency situations. Making a connection in pipes is strictly prohibited. The resistance between the pipe and wires is at least 0.5 megohms.

Installation must be carried out in such a way that, if necessary, the wiring can be removed without much effort. Connections are made using couplings and fittings.

What does grounding protect against?

Thanks to grounding, it is possible to protect households from electric shock when touching the pipes. The effect of electric current is manifested as follows:

| 0.6 - 1.5 thousand μA | A person feels the effects of electric current in his body. |

| 2 - 4 thousand μA | Fingers begin to tremble, a person cannot stop it. |

| 5 - 7 thousand μA | Brushes cramp. |

| 10 - 15 thousand μA | Without the help of others on their own, a person cannot unclench the fingers of the hand in which the conductor is located. |

| 20 - 25 thousand μA | It is difficult to breathe, it is not possible to free itself from the effects of the conductor, severe pains appear. |

| 50 - 80 thousand μA | Disturbances in the heart, paralysis of the respiratory system occurs. |

The range of metal pipes for electrical wiring is quite extensive, in order to purchase the most suitable option, you need to familiarize yourself with the design features, its advantages and disadvantages.