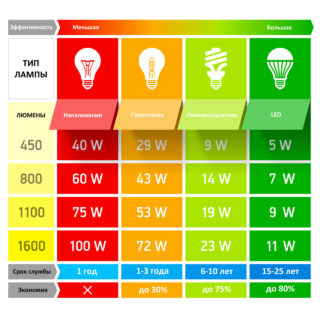

Fluorescent lamps are lighting fixtures that save energy compared to classic light sources. Fluorescent lamps are used for lighting residential, work and industrial premises. Their work is based on the luminescence effect. To choose a suitable light bulb, you need to know the design features and specifications.

Principle of operation

A fluorescent lamp is a gas-discharge light source. Radiation is due to the reaction of a mixture of gases in the flask. Previously, such devices were practically not used in domestic conditions, as it was believed that they could harm vision. But after research, scientists came to the conclusion that the rays are perfectly perceived by the human eye. What a fluorescent lamp consists of depends on its purpose. The mixture of vapors inside may be different.

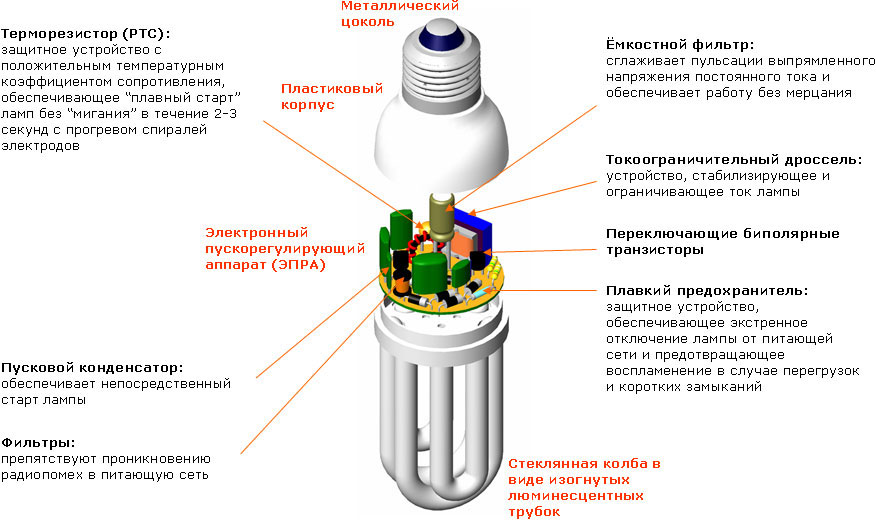

Structurally, the device is a glass tube flask, on the inner surface of which a phosphor is applied. At the ends are electrodes. Inside the tube are mercury vapor and a mixture of gases.

The principle of operation of a fluorescent lamp is as follows:

- Under the influence of an electric field, a gas discharge occurs in the bulb.

- The current that passes through the vapor causes ultraviolet radiation, which causes the phosphor to glow.

The flask is made of glass, which does not transmit UV rays, but gives only visible light. An exception is bactericidal lamps, the use of which requires the emission of ultraviolet light.

The advantages of fluorescent fluorescent lamps:

- high light output;

- energy saving;

- durability - high-quality materials are used for the manufacture of shades;

- duration of work;

- variety of shapes and sizes;

- wide range of color temperatures;

- creates warm natural light close to daylight.

Disadvantages:

- the presence of harmful components in the llama (mercury);

- complexity of disposal;

- restrictions on the number of on and off cycles;

- sensitivity to humidity;

- full inclusion does not occur immediately;

- may hum and flicker during work;

- dependence of stable operation on temperature.

The optimal operating temperature of the device is +20 degrees. The permissible range is 55 degrees, but it is constantly expanding with the development of technology and the use of electronic ballasts.

The cost of daylight bulbs is lower than that of LEDs. But it is larger than that of incandescent lamps or halogen appliances.

Varieties of fluorescent lamps

Classification of fluorescent lamps can be carried out by power, temperature, shape, installation method, length. The most common are high and low pressure lamps. High pressure devices are used on the streets and in high-power luminaires. Low-pressure bulbs are suitable for chandeliers in residential and industrial premises.

According to the type of installation, light sources are classified into the following groups:

- outboard;

- portable;

- ceiling;

- wall mounted.

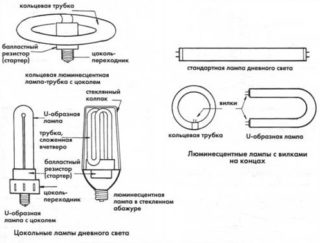

By the structure of the lamp there are:

- compact;

- ring;

- U shaped;

- direct.

Most often, an annular and direct short or long lamp is used for lighting. Also, devices operating on battery or batteries are actively used.

Application area

Daylight lamps are widespread due to their advantages. They are used for lighting in homes and apartments, offices, industries and warehouses, in street lighting and light advertising.

Depending on the color rendering spectrum of the lamp, there are:

- similar to solar radiation - used in the illumination of offices, production halls, administrative organizations;

- with high color rendering - suitable for exhibitions, galleries, museums, hospitals, organizations selling dyes, fabrics and other artistic devices;

- with increased radiation in the red and blue spectrum - used to illuminate aquariums, greenhouses, in plant stores, greenhouses;

- with a shift to the blue and UV part of the spectrum - decoration of aquariums;

- light in the UV spectrum - tanning salons;

- UV radiation of increased power - antibacterial lamps.

Before the active use of LEDs, fluorescent luminous bulbs were used to illuminate liquid crystal monitors. Powerful fluorescent devices are used in street lighting of tracks, stadiums, venues.

Specifications

The main technical characteristics include:

- Color rendering. This is one of the main characteristics of a light source. It is determined by the composition of the phosphor. Fluorescent devices have a wide color gamut thanks to many different compositions. The most common for home use - devices with a color temperature of 2700 K, giving a warm natural shade. In advertising and architectural lighting, devices of different colors are used - pink, blue.

- Basement You can select 2 forms of the cap, depending on the design - pin and cartridge. Pin caps are used in fixtures in which a U-shaped bulb is installed. Cartridge socles have a classic appearance with thread of different diameters. Used in home fixtures.

- Voltage. The working power supply is 220 V, less commonly used is a serial connection of the spirit of the lamps, operating at 127 V.

- Power. The most common are 18 V. lamps. There are more powerful sources for projectors, reaching 80 watts.

- Life time. Can reach 40,000 hours.

- Efficiency above 20%.

- Physical dimensions For example, Armstrong lamps have standard sizes for a cell of 600x600 mm.

- Degree of protection against dust and moisture. Determines the possibility of safe operation in certain climatic conditions.

- The material of manufacture. Plastic, metal and others.

When choosing a lamp, you need to take into account the technical characteristics, as well as the parameters of the lamp in which the light source will be installed.

Network connection

Gas discharge light sources cannot be connected directly to the mains. This is due to the fact that the lamp has increased resistance in the off state, so a high voltage pulse is needed for ignition. After the appearance of a charge, a negative differential resistance appears in the bulb, which requires the inclusion of an additional resistor in the circuit. Otherwise, the light source will break.

To solve these problems, ballasts are used. The most common are two types - electromagnetic ballasts EMPR and electronic ballasts ballasts.

EMPRA

Devices with an electromagnetic ballast are a choke, which has a set of inductive resistances. It is connected in parallel with a luminescent source of a certain power. Using a choke, a starting pulse is formed and the electric current passing through the bulb is limited. Benefits include:

- high reliability;

- simplicity of construction;

- long service life.

Disadvantages:

- launch time is 1-3 seconds;

- requires more energy than electronic ballasts;

- buzz;

- flicker

- large sizes;

- does not work at low temperatures.

The starter circuit is used in the connection scheme, which is a neon lamp connected in parallel with a capacitor. The starter has 2 electrodes - rigid fixed and bimetallic, which bends when heated. The electrodes in the normal state are open, they close when an electric current is applied.

To create a resonant circuit, a capacitor with a small capacitance is connected in parallel. This helps to form a long pulse to ignite the light bulb.

Electronic ballasts

The electronic ballast is characterized by the absence of a blinking light bulb. It supplies the light source with a high-frequency voltage reaching 133 kHz. There are 2 types of electronic ballasts by the way of starting:

- cold - the lamp glows immediately after switching on, suitable for fixtures that are rarely used;

- hot start - the electrodes warm up, the lamp lights up after 0.5 - 1 sec.

Benefits:

- quick start;

- energy consumption is 20-25% lower;

- less material costs for disposal;

- the availability of devices with a dimmer.

Compared to lamps using electromechanical ballast, an electronic ballast does not require a starter. Ballast can independently form the necessary sequence of stresses. There are different ways to start the lamps. The cathodes are usually heated at a higher frequency than the mains.

In the circuit, the components are selected so that, in the absence of charge, electrical resonance occurs. It leads to an increase in voltage between the cathodes. This leads to easier ignition of the bulb.

Major malfunctions

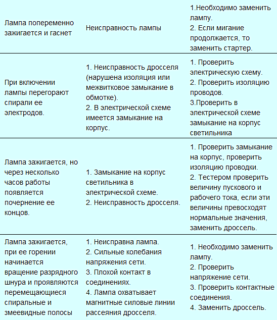

The main reasons why fluorescent fluorescent lamps fail, include:

- Worn tungsten filament. From a tungsten filament, which is coated with an active mass, electrodes are made. Over time, the coating collapses and crumbles, due to which the thread breaks down.

- Constant starter operation in light bulbs with EMPR. It is directly related to the burnout of the electrodes. With a constant actuation of starters, the lamp starts to blink, which negatively affects human health.

- Throttle malfunction. If the inductor breaks, the electric current in the circuit increases significantly, due to which the electrodes sharply heat up. Under the influence of high temperatures, the electrodes are destroyed, and the lamp stops working.

- Poor protection in lamps with electronic ballasts. In devices with electronic ballast, an automatic shutdown circuit is established when the lamp burns out. In cheap devices of an unknown manufacturer, protection may be of poor quality or not at all. This leads to an increase in voltage and burnout of ballast transistors.

- Wrong choice of capacitor. If the capacitor does not fit the lamp power, a breakdown will occur.

If the lamp breaks, self-repair is difficult. It is recommended to consult a specialist or purchase a new device.

Marking Fluorescent Tubes

There are 2 types of marking of fluorescent lamps - domestic and foreign.

Domestic marking is recorded in alphanumeric form:

- The first letter - L, means "lamp."

- The second characterizes the luminous flux (D - daylight, CB - cold white, TB - warm white, EB - natural white, B - white, UV - ultraviolet, K - red, Z - green, D - blue, C - blue, F - yellow).

- The third letter is the color rendering quality. There is C - improved quality and CC - especially high color rendering.

- The fourth letter is the design. A - amalgam, K - circular, U - U-shaped, B - quick start, P - reflector.

- The number indicates the lamp power in watts.

Also, the natural white color can be marked with the symbols LE - natural and LHE - cold natural.

Special lamps also have their markings.The letters LN, LK, LZ, LV, LR, LGR, LUF are marked with colored lamps.

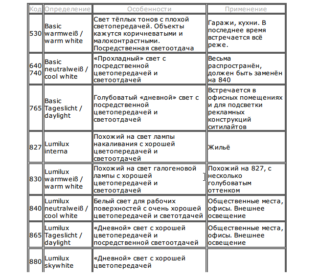

In foreign marking, a three-digit code and a signature in English are used. The color rendering index (first digit in 1x10 Ra format) and color temperature (last 2 digits) are recorded in digital form. In houses, sources with the marking 830, 840, 930 are used.

Light bulb recycling

The harmful substances that make up the lamp require special disposal of the device after failure. It is forbidden to throw out lamps together with household garbage - this can lead to environmental degradation.

To properly dispose of devices, special collection points have been created. They are in the management companies of the district, it is prescribed by law. You can rent a light bulb for free.