When installing power lines and domestic wiring, it is difficult to do without high-quality cable products that guarantee long-term operational reliability of the laid routes. VVG wire is one of the most common product samples that meet the basic requirements of the PUE in terms of arranging cable networks. It is characterized by resistance to destructive influences, characteristics suitable for the stated purposes and quite reasonable price per linear meter.

Application area

Electric VVG cables are widely used in laying, replacing or repairing various types of electrical wiring, as well as in organizing individual bends from overhead lines. Most often, the need for an electric cable VVG arises in the following cases:

- when supplying power from transformer substations to residential buildings and input devices of industrial facilities;

- in a situation where you need to lay a single-phase or three-phase cable line from a high-voltage branch to a particular private house, for example;

- for wiring internal electrical networks (wiring) at facilities of various categories;

- when laying wiring in medical and child care facilities (in this case, special non-combustible modifications are used).

As a special case of its use, we can consider the wiring of city apartments.

VVG electrical cables are not intended to be laid directly underground, since there are no samples in the armored protection in their lineup. To assess the scope of the selected model, it is enough to understand its labeling, which reflects all the necessary information.

Design Features and Specifications

When considering the characteristics of the composition of cable products, it is important to know that it is classified according to the following main characteristics:

- real conditions of laying and operation;

- the number and cross-section of wires of the VVG cable;

- degree of protection against destructive factors.

In accordance with the first of these, these products are divided into samples intended for installation indoors or outdoors (outdoors).

In the case of their external installation, the use of special protective structures is mandatory: metal sleeves, as well as steel pipes or trays.

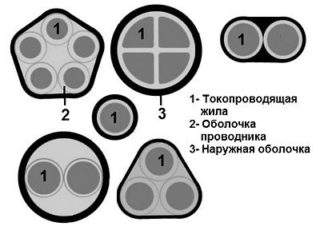

By the number of copper insulated conductors included in them, there are two, three, four, 5 and 6 core. The cross section varies widely (from 1.5 to 250 sq. Mm).

When describing the characteristics of cable products, in addition to the indicators already listed, the maximum permissible current per one core is necessarily mentioned. Its value corresponds to the value characteristic of the VVG section, adjusted for the number of conductors. By the degree of protection, these products are represented by samples in the usual design and wires, characterized by increased resistance to destructive influences.

A high degree of security is achieved through the use of double insulation: each of the wires individually and the common outer shell.

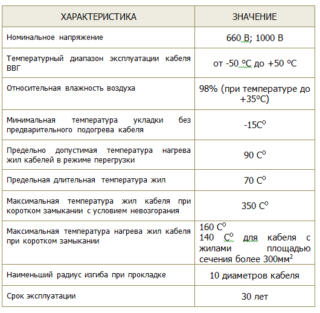

The service life of products of this class, according to the current GOST, is at least 30 years. Sometimes the characteristics indicate the length of the cable stored in standard round bays.

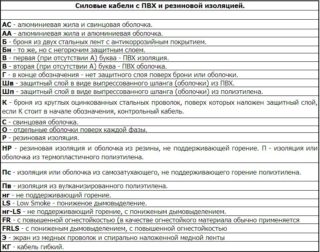

Decoding of markings and possible modifications

When familiarizing oneself with cable products of the VVG brand, attention is primarily drawn not so much to the appearance as to the marking.It contains data on the material and cross-section of current-carrying conductors, as well as detailed information on the type of insulation of the inner and outer shell. Decoding and application of the VVG base wires have a direct connection, which is manifested in the following:

- the absence of the letter “A” in the first position means that pure copper was used as the core material;

- two “B” icons indicate that the shells of individual cores and the external general insulation are made on the basis of durable polyvinyl chloride;

- the letter “G” standing in the next position indicates that the cable does not have protective armor; such a product is not allowed to be used for laying underground;

- the letter "T" added to the main designation through a hyphen indicates a tropical performance of this model.

The symbols following the main designation should be understood as versions that differ in some technical indicators.

For an exact decoding of the brand of VVGN wire, for example, you will need to know the meaning of the last “H” symbol, indicating a special modification of this product. As an example of designation, consider a sample of a cable of the VVG-T 3x25-0.66 brand.

- This is a model of VVG cable made in the tropical version;

- the product itself incorporates three monolithic veins;

- the cross section of each of them is 25 mm2;

- This brand of cable is designed to operate at an effective voltage of no higher than 0.66 kV.

Lists of possible cross-sections of cores depending on their number and operating voltage are given in special tables placed in thematic sections of the Internet.

Non-combustible VVG

Fire safety marking is expressed in the presence at the end of the console of the symbols “NG” indicating that this cable sample is non-combustible. In its shell during production, special ingredients are added that contribute to the attenuation of combustion.

The VVGNG cable is multi-wire and its modification with the LS mark is a type of non-combustible type that forms a minimum of smoke during decay and does not emit toxins at all. Such products remain operational for a long time and are used in emergency lighting systems and places with increased fire safety requirements.

Another variety of cable products under the designation VVGNG HF is characterized by the fact that it does not contain halogen substances (including chlorine) in its shell. A product brand VVGNG FRLS refers to a modification characterized by maximum resistance to open fire in group laying conditions. Its ability to resist the effects of an open flame with minimal smoke formation is explained by the presence of a special mica component in the outer protective shell.

Shape of cores and cable sheath

According to the shape of the sheath, cable products are divided into flat and round samples. As an example, consider the VVGP NG decryption wire and the use of which is associated with the following features:

- the designation indicates that it is a flat power wire with two or three cores;

- APG wire is used for laying in inaccessible places;

- with a cable of this brand, it is easier to trace with a large number of flat bends.

In all other modifications, the shape of the shell is standard (rounded).

According to the cross-sectional configuration of individual copper conductors, well-known VVG samples are divided into products with round and segment tires.

Any modification of the VVG cable is protected externally by a polyvinyl chloride sheath that does not support combustion with a single installation. In the case of group use of cable products of this brand, it is necessary to choose models that have the prefix "NG" in their designation. For all other options for using products of this class, a special marking is added, which is added to the main designation through a hyphen.