A wire of grade PV-3 with a cross section of 6 mm is considered a universal solution for connecting power units and devices, as well as for organizing grounding lines. In order not to confuse these communications with each other, a color difference is provided. The advantage that the wire PV-3 1x6 has is increased flexibility, which facilitates installation in hard-to-reach places.

Design features and decoding of marking

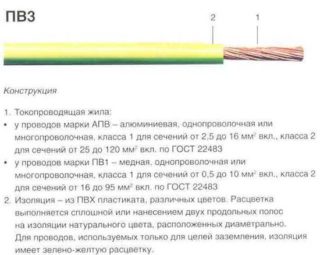

The PV-3 wire is a one-piece construction of a multi-wire copper core and insulation made of polyvinyl chloride. At the same time, GOST allows a single-wire design, but it does not occur in stores due to several drawbacks, among which there is low flexibility and increased fragility.

Marking:

- P - wire;

- B - PVC insulation;

- 3 - flexibility class of a copper wire core.

Insulation can be both monophonic and two-color. A common form of mixed colors is yellow-green. This marks the wires intended for the organization of grounding loops. Due to the multiwire structure of the core, the product has a high conductivity.

Specifications

The yellow-green wire PV-3 1x6 has sufficient endurance to be used in extreme conditions. Its insulation is able to withstand temperatures from -60 to +70 degrees Celsius. It is immune to steam or condensate.

The polyvinyl chloride of which the insulation is made is not susceptible to mold. It does not burn, but melts, which makes it possible to avoid a fire when exceeding the permissible load and overheating of the core. Advantages of insulation are strength, durability and unattractiveness for rodents. The standard life is 15 years, after which the properties of the wire can change for the worse, and it must be replaced.

With a cross-section of a core of 6 square meters. mm PV-3 can withstand current up to 46 A, if laid separately, and up to 35 A, if there are four conductors nearby. The weight of one meter of such a wire with a cross section of 6 mm2 is 0.07 kg.

The core is made only of copper. According to GOST, the use of bimetallic veins is unacceptable.

Application area

PV-3 can be used in the organization of domestic and industrial electrical networks. Its versatility and unpretentiousness make it possible to use it when installing apartment electrical wiring, factory communications, for connecting electrical equipment in a garage, etc. Resistance to steam, moisture and condensation makes it possible to use this wire in baths, saunas and other rooms with high temperature and humidity.

Double insulation provides for the use of PV3 1x25 wire when laying networks with voltages up to 1000 V only indoors. It is not able to receive heat from a copper core, therefore the probability of its melting during overload tends to zero. Its disadvantage is the lack of resistance to direct sunlight, so installation on the street is prohibited.

Separately, it is worth noting the possibility of using wires during the assembly of electrical cabinets. Its flexibility and resistance to temperature effects are the best suited for creating short jumpers between power blocks. In this case, the ends must be necessarily crimped using the appropriate cross-section of the tips in order to avoid heating of the core at the contact point.When using clamp connections, the terminals are looped in at the ends of the wire.

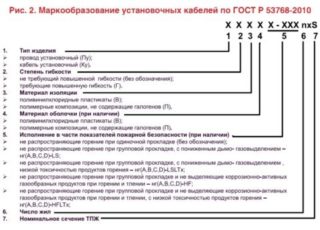

Differences between PV-3 and PuGV

Markings differ from each other only in that described in different GOSTs, one of which is outdated. Therefore, PV-3 and PuGV are the same wire with different names. The first is described in GOST 6323-79, which has already been abolished. The second came to replace him, his characteristics are included in GOST R 53768-2010. The main difference between the PuGV wire from the PV-3 can be considered a higher flexibility class (fifth), which appeared in the new PuGV. In stores PV-3 is less common, due to the fact that it is no longer produced by enterprises.

With the release of PuGV, some changes are made to the insulation composition that increase its reliability. In the new modification, additional components appeared that have a sharp chemical smell that repels rats and mice.

PVC has received additional abrasion resistance, which allows the use of this wire in some movable structures for short-term use.

Wire routing conditions

Given the versatility of the PV-3, it is difficult to talk about any limitations during its installation. It should be used in stationary systems, as constant movement and bending can damage the copper core. Laying can be carried out in special cable channels, sleeves, trays and strobes. Bends up to 90 degrees are allowed with a radius of 5d. When mounting several PV-3 wires with a cross section of 6 mm2, the maximum permissible current is simultaneously reduced. This point should be considered when designing communications.

Given the versatility of the PV-3, it is difficult to talk about any limitations during its installation. It should be used in stationary systems, as constant movement and bending can damage the copper core. Laying can be carried out in special cable channels, sleeves, trays and strobes. Bends up to 90 degrees are allowed with a radius of 5d. When mounting several PV-3 wires with a cross section of 6 mm2, the maximum permissible current is simultaneously reduced. This point should be considered when designing communications.

The wire can be used to organize temporary networks without additional external protection. At the same time, it must be fixed with brackets or clips to fixed parts of the equipment or wall. Long operation in this mode can lead to damage to the insulation and a violation of its properties, as a result of which breakdown is possible.

Purchase Check

The flooding of the market with fake cable products makes us carefully check the PV-3 wires before purchasing. To buy a quality product, you need to follow a few simple tips:

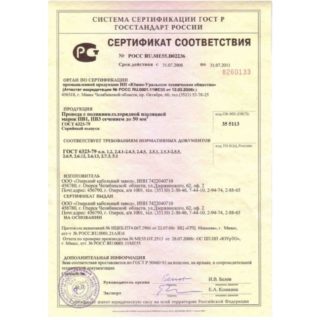

- Choose products that have the marking in accordance with the relevant GOST, and not TU. Manufacturers strive to tailor the technical conditions for themselves in order to reduce costs, and produce products that do not meet the standards.

- The information printed on the insulation must be fully consistent with that contained on the tag of the bay. If there are discrepancies, the product may be counterfeit or non-compliant with GOST.

- The cross section must be checked with a caliper, as some manufacturers intentionally produce a “truncated” wire.

- The seller must provide a certificate of conformity, which will contain information regarding the test wire for breakdown, as well as the resistance of the core.

If desired, you can additionally test the resistance using a high-precision ohmmeter. Knowing the length of the wire, determining compliance with the declared characteristics is not difficult.