When installing electrical wiring, the main cable enters the switchboard, and several conductors depart from it. To prevent overheating of the wires and ensure reliable contact, an electrical cross-module is used for wiring in the shield.

Cross module definition and purpose

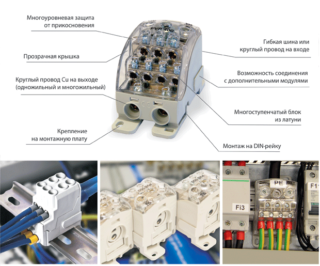

The cross-module is a device inside which insulated metal tires are placed. They are designed for connecting outgoing wires of different cross-sections with screw clamps.

The cross-bus is made of electrical copper or brass, providing fire safety. All elements of the device are placed in a protective plastic case. There is a hinged lid for access inside.

The use of a modular switchgear avoids unreliable and fire hazardous cable bundles in the switchboard and greatly simplifies installation. The device is small and can be compactly installed in the panel itself.

Wiring and connecting wires takes a matter of minutes, a screw clamp of the bus provides reliable contact between the zero and the power core. This is especially important for industrial enterprises, where dozens of branches can depart from the distribution panel.

Three Phase Cross Module

The three-phase unit is equipped with 4 metal buses for connecting the neutral wire and three power phases A, B, C. The number of outgoing connections can be from 7 to 15. Outgoing wires can be used both single-phase for lighting and sockets, and three-phase for connecting industrial motors.

If there are a large number of outgoing cables, a cross-module on a DIN rail will help unload the system, the 3 phases of which will be compactly arranged for easy assembly. In addition, several devices can be placed on a DIN rail.

Advantages of the modular distribution block

The use of cross-modules in the installation of electrical wiring has several advantages compared to conventional twisting. They are as follows:

- First of all, it is fire safety. Reliable fastening of wires to metal tires does not allow sparks due to leaking contact. The presence of a bus with zero phase prevents the occurrence of a short circuit.

- Easy installation of wiring. Such work can be handled even without much experience. The entire process of mounting, wiring and connecting wires is quick.

- The ability to connect cables of different sections.

- With a large number of connections, several interconnected devices can be installed on one DIN rail.

- The absence of heaps of bundles of wire twists, attractive appearance of the distribution panel, the ability to visually view the status of all connections.

These qualities contribute to the widespread use of distribution blocks when installing wiring in industrial enterprises.

The cost of purchasing devices and installing wiring quickly pay off due to the failure-free operation of the system for a long time.

Cross module installation

Cross-modules are mounted on the wall in two ways: using screws or on a DIN rail. The first method is rarely used when it is necessary to install only a separate unit.When mounting on a rail, you can simultaneously install several different electrical devices connected together by wires, which is very convenient and compact.

The mounting DIN rail is fixed with screws in the place where the unit is supposed to be installed. The length of the slats is cut off based on the number of devices that they plan to install. For mounting in the cross modules, special grooves are provided, so the installation is quick and reliable.

IEK Cross-Module

A preliminary diagram of the distribution panel is made taking into account the fact that the unit must have free access for installation work. The selection is carried out taking into account many factors: the cross-section and the number of connected wires, the dimensions of the model, the maximum load in amperes and the ability to install the unit on a DIN rail together with other electrical devices.

One of the main criteria that you need to pay attention to when choosing a distribution block model is the maximum current load in amperes for which the device is designed. If it exceeds the figure specified in the technical documentation, the wires will heat up, cable ignition is possible.

To prevent such cases, special protective devices such as MZN or MZT are installed in the system. The IEK cross-module provides additional protection: all buses inside the unit are isolated from each other. This makes it possible with certain skills to connect the wires without even removing the voltage from the unit. Thanks to this design, the IEK cross-module is considered one of the most used devices.

Design features, varieties of cross-modules

Depending on the number of metal buses, distribution blocks can be used in single-phase or three-phase networks. They differ in the number of compounds and the value of the load. In addition, there are three types of models for switching wires for various purposes:

- Zero. In the plastic case there is one bus with clamps. Connection of wires with screw terminals.

- Phase. Outwardly similar to zero, only the bus is designed for high load at a voltage of 1000 volts and a current strength of 500 amperes. The case of such a device is made of heat-resistant plastic.

- The combined type in which the buses for connecting the phases and the neutral wire are placed. For industrial networks with a large number of branches, such a cross-module is the most suitable option.

Industry produces distribution block models for information networks. Used to connect optical fiber and twisted pair.

The use of switchgears can significantly accelerate installation work when laying electrical networks. A large selection of manufactured models will provide any customer need.