Any room, especially residential, has a power supply system. It provides the operation of electrical appliances and lighting. To create an electric network, different conductors are used - cables, cords, wires. They can be mounted open and hidden. In all cases, for additional protection of the product, special boxes and cables are used that do not allow mechanical impact, and also reduce the negative impact of the environment. On sale you can find various types of such products with their own differences, operating requirements and characteristics.

What is a box for electrical wiring

Modern wires have great strength and reliability, as well as resistance to climatic conditions. But this is not always enough, therefore, to improve safety, boxes for electrical wiring are used. These are rectangular products of various sizes and lengths into which cables are laid. Usually used with an open wiring method.

The channel consists of the following parts:

- Base (tray). This is a half box with a base and side walls. Holes can be made in it, thanks to which the product can be mounted on the wall and wired. In the absence of such holes, you have to drill them yourself in previously marked places. To fix the upper part on the side walls there are special protrusions. They are a castle.

- The upper part (cover). The design is the same as the base. On the inner perimeter there are recesses for protrusions from the side walls for fixation. The outside is a smooth surface, sometimes with patterns.

When the conductors are laid in the base, the upper part is put on top and closed. It should be securely fixed and easy to open. It is important to check this fact in advance in the store, otherwise it will be problematic to operate the product.

Box materials

Different materials are used depending on the type of wiring. For open metal, wooden, electrical electrical boxes are suitable. Their choice depends on the appearance of the rooms, the financial capabilities of the buyer, the number of wires and external climatic conditions.

Metal boxes

These are robust and reliable designs that eliminate the risk of damage to the open cable from mechanical stress. They are made of materials resistant to the formation of corrosion. The disadvantages include the low electrical safety of the material. Failure to properly wire or use products with poor insulation can result in electric shock to people. Also, metal products are not allowed in humid rooms (bathroom, basement, attic), since water leads to a decrease in the life of the unit. Corrosion resistant boxes are more expensive.

To install a metal box, a special tool for working with metal is required - a hacksaw, scissors, a drill. Not every house has such devices, and their price is quite high.

Wooden box

Such products are used infrequently, although they have their advantages. The positive aspects include:

- Eco-friendly natural material. It does not emit harmful substances, and also does not cause difficulties in disposal.

- It is a dielectric and does not conduct electric current. For this reason, conductors without insulation can be laid in it.In the event of damage to the insulation layer, the person will not suffer.

- Safety. It can be used even in rooms with wires with conventional insulation.

- Aesthetic appearance. Wooden boxes fit particularly well in a country-style room.

The main disadvantages:

- Quick failure if operating conditions are not observed. Especially dangerous is the effect of moisture on wood.

- Increased fire hazard. Wood can catch fire from the slightest spark.

- A possible short circuit can cause a fire of the product itself and the entire room.

Wood products are practically not used. But if the owner of the house decided to put them, you should treat the boxes with special protective equipment.

For installation you will need a hacksaw for wood and a drill. They will allow you to drill holes in the base of the part for fixing to the wall.

Plastic boxes

Most often, plastic channels are used in everyday life. They have the following positive qualities:

- Low cost. It is connected with the low price of the manufacturing material itself - plastic, and the simplicity of the production process.

- Mass production of plastic products due to the development of modern technology.

- Resistance to the negative effects of moisture, fire, acids, fungi, mold.

- Resistant to mechanical stress.

- Electrical conductivity.

- Possibility of use in conditions of high humidity.

- Easy to connect and pull wires.

- No special tool required.

- A wide range of colors, so that the box can organically fit into the color scheme of the room.

Despite the large selection of colors, it should be understood that the plastic box will still be visible on the wall. For this reason, you also need to think in advance how to lay plastic boxes for wiring so that they do not spoil the appearance of the room.

Installation of different types of channels

Conventionally, channels can be divided into several groups at the installation site. They will have their own characteristics.

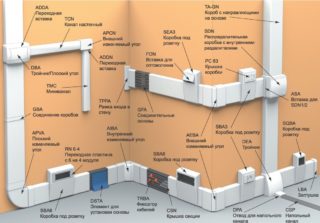

Floor

These designs are used to protect information wiring and fiber optic cables. Provide a high level of electrical safety during redevelopment.

The design allows easy access to damaged parts in case of emergency. In addition, such cable channels are used to bring conductors to service racks.

The base is steel or aluminum. It provides high strength and operation at temperatures from -15 ° C to + 60 ° C.

Baseboards

Such cable ducts floor have several chambers in which power and information lines can be stacked separately from each other. As the name implies, such devices are recommended to be laid under the baseboard, and not on the walls.

It is possible to display the wiring laid under the baseboard at any point convenient for the user. An important visual advantage is the coloring of such boxes. Usually they are made like wood, making it difficult to distinguish them from ordinary wooden skirting boards.

Angular

Similar products are complementary to ceiling and baseboards. They have section sizes from 10 mm to 300 mm and above. They allow several cables to be run simultaneously. The shape is straight and rounded.

Wall mounted

For laying conductors on the walls, boxes made of PVC material are used. Their installation does not require special knowledge and skills, and they also have a small weight. They can be mounted both on special clamps and on an adhesive base.

Parapet

Plastic conduits for wiring have external, flat and internal angles that allow installation as quickly and accurately as possible. Sold about 2 meters long. The range of operating temperatures is from -32 ° C to + 90 ° C.Mounting is recommended at temperatures from -15 ° C to + 60 ° C.

Flexible

Roll or flexible junction boxes are rectangular. Double-sided tape is attached to the side walls for quick and high-quality installation. There are also holes that allow fastening with screws to the surface. An instantly damping PVZ with increased strength is used as the duct material.

Has a wide color variety. The minimum size is 7x12 mm, the maximum is 18x33.

Channel Selection Criteria

For the right choice of electrical boxes for electrical wiring, you need to consider a number of factors.

- Dimensions fixtures. The wire should fit into the channel without difficulty, but it should not leave a large amount of space. You also need to consider in advance how many cables will be placed in one channel.

- Box material. It is determined by the installation location, climatic conditions, financial capabilities of the buyer.

- Boxes for electrical wiring have a certain length. It is recommended to take them with a small margin.

- In the case of laying cables in the house, it is recommended to take lightweight boxes made of plastic or metal, suitable for the design of the room.

- You will definitely need to purchase additional accessories (clips, connectors). It will allow you to securely fix the box to the surface.

- All fasteners and blanking plugs must be in place. It is important to check if the cable box is opened by hand. The master does not have to exert much effort to remove the upper part.

- Appearance should match the colors of the room, outlets, switches.

Do not open the wiring conduits with sharp objects such as a knife or screwdriver. They can scratch the boxes, even if they are metal. The cable itself and its insulation may also be damaged.

Wall Mounting Methods

Correct fixation also affects the duration of the product. There are several ways to fix the cable channel to the wall:

- Self-tapping screws. The laying step is calculated in advance, which depends on the load on the box, the number of wires, and the size of the cross section. The average step is 50 centimeters. If the wall has an uneven surface, the step must be reduced to visually hide the gaps and defects of the wall. No need to take long self-tapping screws, just a 40 mm long product is enough. Application - wooden and plasterboard walls.

- Dowel nails. Usually used for mounting on concrete and brick surfaces. On the basis of the cable duct, holes should be made every 50 cm with a diameter of 6 mm. The channel should be attached to the wall and using a pencil to place the place where it will be mounted. In these places, you need to drill holes, then the box is applied and the dowel-nails are driven in.

- Bedbugs. These are special mounting clips that are used for mounting on metal up to 2 mm thick or on aluminum profiles.

- Liquid Nails. Apply when the above methods cannot be used. An example is a tile in a bathroom, a metal smooth surface. It has poor reliability, therefore it is used as a temporary method of fastening.

The choice of the best method depends on the material of the walls.

Installation Recommendations

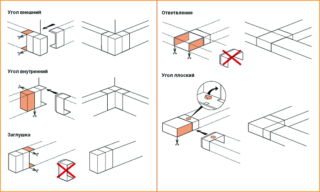

Compliance with the installation instructions is a must when carrying out work. There are a number of tips and tricks to help ease the installation and make it more reliable.

- The wall must be aligned before installing the box. Otherwise, reliable fastening of the box will fail.

- If you want to connect the cable channels in the corners or make branches, you need to make an incision at an angle of 45 °.

- It is allowed to mount channels in the vertical and horizontal plane without intersections. Other laying methods are prohibited.

- Before fixing the structure, you need to mark the surface with a pencil.

- Laying cable channels starts from the corners. Next, the lines themselves are laid.

These simple tips will help the master in creating high-quality and reliable wiring in the boxes.