The polarity of the appliance is the most important component when connecting. If the polarity is violated, the device may fail and lead to negative consequences. Usually the positive and negative wires are marked with letters, symbols or color. But sometimes it is not possible to determine the ownership of the core, then testers are used in other ways.

Wire classification options

Conductors have two types of marking - color and alphanumeric. By these designations you can understand what the product is made of, what is the purpose of the core, what material and other important parameters.

Wires can be classified by the following indicators:

- Number of cores. Depending on the number of cores, the conductor can be used to provide power to the electric motor, electrical wiring, and electric current transmission in power networks. The flexibility of the product also depends on the number of cores.

- Material. Copper is mainly used to create current-carrying conductors, as it is more resistant and has good characteristics. Previously, aluminum was used - it quickly collapses, has a short service life and is inferior in properties to a copper device.

- Insulating layer. Insulation may or may not be present on the conductor. It is made of a dielectric material and protects the product from mechanical damage, external influences, as well as a person from electric shock.

- Section. The load that the cable is able to pass through itself depends on this indicator.

- Other indicators. Power, voltage, operating temperatures, operating conditions are also important for the choice of conductor.

Thanks to the listed properties, you can choose the right wire for different purposes.

Why do you need a stain

Novice masters who only master the basics of electrical engineering, can not immediately determine if the white wire is a plus or minus. Coloring is important in the identification of cores and is called marking.

Color marking of conductors is a necessity that allows the master to quickly navigate, for which each core is responsible. With its help, you can understand what color the zero wire is and where the phase is located. It also makes it easier to read electronic circuits.

Especially important is the observance of color marking when connected to meters, machines, devices. Without painting, it is difficult to figure out which device could fail and which circuit it is connected to.

Manufacturers paint cables in certain colors established by the rules of electrical installations of PUE. They strictly regulate what labeling should be used for a particular core.

In addition, it is important to understand that the positive and negative contacts in the DC circuit have their color. What color is the plus wire, also set by the rules.

In the case of unlabeled cable of the same color, a label with information can be placed at the ends of the product (for example, on a heat shrink tube).

Color phase

When installing electrical wiring, phase conductors are of particular danger. If you touch the phase, a person can get an electric shock, which can harm health or lead to death.The color in bright colors allows the master to determine that in front of him is the phase conductor.

When installing electrical wiring, phase conductors are of particular danger. If you touch the phase, a person can get an electric shock, which can harm health or lead to death.The color in bright colors allows the master to determine that in front of him is the phase conductor.

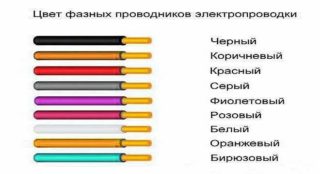

Typically, the phase is painted in red and black, but other colors can also be found (orange, brown, pink, purple, white, turquoise and others).

If the electrician does not know exactly what color the phase is, you can go by the method of exclusion. The zero and ground wires have a strictly defined color, and then the remaining core is a phase.

In the diagrams, the phase is indicated by the Latin letter L. If there are several of them, a digit is added - L1, L2, L3 for three-phase networks of 380 V. Also, the designation A, B and C is found in electrical networks with three phases.

Ground wire color

Modern standards regulate the yellow-green color of the earth. Coloring can be performed in the form of transverse yellow-green stripes or as a yellow insulation with one or two longitudinal strips of green.

Modern standards regulate the yellow-green color of the earth. Coloring can be performed in the form of transverse yellow-green stripes or as a yellow insulation with one or two longitudinal strips of green.

Some manufacturers produce a bright green or yellow ground wire. Identifying the earth in this case is not difficult, since such a coloring is prohibited to indicate the phase. A similar marking is used on electrical circuits. The letter designation is PE.

Some experts incorrectly call the earth a “zero and protective” wire. This can confuse others, you need to understand that this is the name of the earth wire. It is by definition protective, since it helps to protect a person from electric shock in case of emergency.

Color scratch

A neutral or neutral wire is traditionally painted blue or cyan, but blue is found with a white stripe. Other shades do not apply to scratch. Also, experts call the neutral conductor a working zero. This expression is correct, since it is involved in power wiring.

In some schemes, zero can be called a minus, and a phase - a plus.

Color of wires and tires with alternating three-phase current

Busbars and bushings for transformers in three-phase networks are painted in a certain way. Yellow is phase A, green is phase B, red is phase C.

Busbars and bushings for transformers in three-phase networks are painted in a certain way. Yellow is phase A, green is phase B, red is phase C.

Such networks have found their application in the following areas:

- Industry, construction, warehousing. Allow you to connect powerful industrial plants, unloading machines and other electrical equipment.

- Electrification of public transport. Trams and trolleybuses operate on a three-phase 380 V network.

- Electrical substations.

DC networks use only two wires - plus (positive bus) and minus (negative bus). Which wire is plus, and which minus can also be understood by color.

According to regulatory documents, the positive bus should be painted red, and the negative cable should be gray or black. The middle conductor is indicated in blue. You can see such a designation of plus and minus on wires on various audio and video equipment, as well as other electronics.

In the case of a branch of a two-wire electrical network, the positive conductor should be painted in the same way as the plus on the three-wire network to which it is connected.

Features of working with electric wires of different colors

There are cases where knowledge of phase and zero is optional. For example, when connecting a new outlet or replacing an old one. When connecting the plug to it, the polarity is not important and does not affect the performance of the device.

In situations where you need to connect the switch to the chandelier, you need to know the phase and zero. The phase conductor is connected directly to the switch, and only zero to the bulbs. Otherwise, the switch will not work.

The use of conductors of different shades greatly facilitated the work of the masters and accelerated the installation process. Also, the color designation has improved safety when working with live conductors.

How to check the correct labeling and exclusion

Color coding is simple and convenient, but you should not completely rely on its correctness. In addition, over time, it can be erased, which makes it difficult to identify the wire. The difficulty lies in the old wires, which were monotonous - white or black. Therefore, before carrying out work, you should check what each core is responsible for.

It is important to de-energize the room before wiring. The wiring at the ends should be cleaned a little, and only then checked with a tester. Otherwise, it may result in electric shock.

Testing with indicator screwdriver

To work, you need a tester. It can be a multimeter or indicator screwdriver. It looks like an ordinary screwdriver, but at the end there is an LED indicator. Her arms are necessarily insulated. It is easier to work with a screwdriver - just touch each core, and if the probe is in phase, the LED indicator should light up. This method is suitable for two-wire wires. The main disadvantage of determining the phase with an indicator screwdriver is the risk of a false positive. It can respond to interference and show the presence of voltage where it is not.

You can buy a device at any hardware store. It is inexpensive and affordable for everyone, unlike professional testers.

Multimeter Test

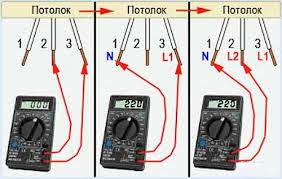

For a three-wire wire, you need a multimeter. Then you can go by the exception - find the exact phase with a screwdriver, and then use the tester to determine the ground and zero.

There are two types of multimeters - digital and analog. The only difference is information output, verification accuracy and internal mechanism. The method of verification from the type of tester will not change. For a home master, you can buy an inexpensive multimeter with limited functionality.

The circular switch must be put in a position of more than 220 V. Then you need to take two probes by the insulated handles and gently touch one probe to the found phase wire, and the second to the remaining conductor. If 220 V or slightly more lights up on the screen, then the wire found is zero. With land, the value will be lower. The verification algorithm is similar.

Determination of grounding, zero and phase using a test lamp

This method is not recommended, as the tester and indicator screwdriver are a more accurate and safe method. But in the absence of tools, you can carry out the following actions, doing everything extremely carefully:

- Screw the bulb into the cartridge.

- Hook wires with stripped insulation to the chuck terminals.

- Connect the tested conductors to the lamp wires in turn.

This method allows you to find the phase conductor. If the bulb lights up, then one connected core is a phase. Otherwise, the conductors are zero and ground.

Other folk verification methods are prohibited. They are unsafe and may result in electric shock.

Self-marking

There are times when the marking is erased or missing / confused. Then, after the dialers of each conductor, you should independently indicate which core is responsible for what.

If the wire sections are completely replaced, you can purchase cables of the desired color. If it is not possible to get a suitable shade, you can make a mark at the ends with a colored electrical tape or a heat shrink tube. The rules allow you to mark the conductor not along the entire length, but only at the points of connection to the tires.