Finishing the installation of electricians in the house, it's time to think about how safety will be respected. If previously used electrical tape, now convenient shrink for wires is popular. Means for laying electric cables is divided into several types that differ in individual characteristics.

General information and scope

The heat pipe for wires is made of polymer with the addition of some chemical composition. It complies with GOST 17675-87 and GOST 19034-82 and is used in practice exclusively for electrical insulation. The device is stored for a long time, it is able to acquire the desired shape during heat treatment. For example, when heating a material worn on a conductor, it narrows, creating a tightness at the switching points. Also shrink tubes can be used in such cases:

- protection of electricians in unusual conditions;

- strong connection on the moving mechanisms giving in to vibration;

- in conditions of increased dampness;

- to isolate electrical contacts in a car.

Each product has its own marking, which determines belonging to a particular type of operation. Many materials are sold pre-packaged.

Types of Heat Shrink Tubing

Thermotubes for insulation of wires are divided into several groups that distinguish them by parameters:

- material of manufacture;

- principle of wiring;

- shell thickness.

Each of the options is suitable for specific purposes, therefore, when choosing for electrical installation, these features must be taken into account.

Production material

The group should include instances that are suitable for reliable insulation of household electrical networks.

- An insulating tube for polyolithin wires is considered one of the most common. It has high strength, created by radiation and chemical treatment. It is operated at a temperature from 50 to 175 degrees.

- Synthetic rubber is resistant to temperatures up to 175 degrees, withstands the influence of fuels and lubricants.

- Polyester. Such tubes are characterized by ultra-thin sheaths, while they have a large diameter and are suitable for insulation of a whole cable bundle.

- Thermoplastic PVC. It has excellent insulation quality, but is not able to withstand temperatures above 80 degrees.

- Silicone heat shrink wire connectors. The material is non-toxic, does not conduct electricity. It is able to deform only under the influence of chemical solutions.

- Ftoroplast. Such a product is considered one of the most expensive, as it is manufactured using sophisticated technology. Differs in ideal operational qualities and universality.

- Connector It is a small piece of tube with an integrated connection mechanism.

PVC insulation has virtually replaced other means to protect electrical connections. Therefore, products are improved annually and demand is growing for them.

Mounting principle

According to the method of use, shrink products are divided into three types: with glue, without it and options with longitudinal sealing.

Glue tubes for insulation of wires are materials that are filled with special sealant, which creates additional strength after solidification.

Glueless devices are put on the connection of wires and warm up, thereby creating sufficient density.That is what they hold tightness.

Instances with longitudinal sealing are heat-shrinkable tape for wires, which includes batilikumuchikoy mastic. When it is heated, the composition expands and fills the space between the conductors.

Shell thickness

According to this parameter, heat shrink tubes are:

- thick-walled;

- thin-walled;

- medium thickness options.

All these tools are equally used at the final stage of electrical installation and are effective.

Shrink Properties

In the process of use, heat shrink tubes exhibit their individual properties, which can be estimated due to the presence of thermopolymers in the composition. For example, when exposed to high temperature on the heat-shrink put on the conductor, it is actively and firmly compressed, so that the quality of the seal remains high for a long time.

For screeding switched areas of electricity, a construction hair dryer or an ordinary lighter can be used. When processing, it is important not to overdo it, otherwise air bubbles will appear inside, due to which the crimp quality will be lost.

When heated, the material does not lose its properties, it is only able to change shape.

The quality control of switching electrical wires can be carried out using a transparent silicone tube.

Characteristics

The main characteristic of this type of insulation is the ability to shrink, which is measured in a ratio of 2: 1, 3: 1, 6: 1 and so on. Heat shrinkage with glue for wires is a rather convenient material that creates maximum strength after heat treatment. Such tools are used to produce secure compounds in complex places.

Marking

By means of marking it is possible to choose the right insulation material. However, it must be read correctly in order to understand for what purposes a heat-shrinkable material is suitable. On the side of the product with a black marker, two diameters are recorded through a fraction. The first indicates what diameter is set by the manufacturer, the second indicates how it will become after shrinkage at the junction. For example, insulation values can be written: 8/4, 60/25, 10/4 mm.

How to choose the right diameter

To easily fit the material at the junction, you should take the option with a size 10% larger than the insulated place.

At the time of crimping and heating, the tube is narrowed by 15-20% of the initial parameter, respectively, the switching becomes reliable and tight.

Do not confuse thermal film for wires with a tube. The first option is used to isolate the connections inside home appliances.

How to use heat shrink for wires

First of all, it is necessary to analyze the features of the cable to which this switching method will be applied. Shrink installation is carried out in a matter of minutes, without requiring special skills and tools.

Preparatory stage

The preparation process consists in choosing the right material and processing it for use. Before you put the heat shrink tubing on the insulation, you must make a neat cut. The segment should be 10% larger than the zone that must be insulated.

DIY heat shrink tubing installation

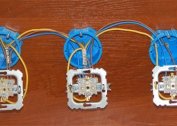

During installation, a fragment of the tube is worn on one side of the wire, after which a connection is made with the second. Then the product moves to the right place and is evenly heated by a hairdryer or open fire (using a lighter) from all sides.

It is important not to overdo it, otherwise the heat shrinkage from overheating can be deformed and slip away.After processing, it is necessary that the insulation cools down, after which it can be packaged in distribution boxes.

An important condition when working with shrink material is compliance with safety regulations. All manipulations should be performed with the electricity turned off.