A pump station in your home is the key to a comfortable life. Having spent a little time on its installation and maintenance, you can relax or do useful things, because you no longer have to carry water in buckets. The pump pumps water from a well or well into a storage tank, will help the central water supply, increasing the pressure. He will turn on at the right time and turn off when the pressure in the water supply system reaches normal. However, all equipment requires proper operation, so you need to know exactly how to properly start or maintain a pump station to supply water at any time of the year.

Features and algorithm of actions when starting up a pumping station

Installation, grounding and start-up of the pumping station must be carried out by a specialist who is authorized and qualified to carry out these works. If this condition is met, there will be no reason to refuse warranty repair in the event of a pump breakdown. However, a competent and skilled man can independently connect the station by reading the instructions and observing safety measures.

The pump station is installed in an insulated room and is protected from the effects of freezing temperatures or flooding. Given the noise of the unit, it is necessary to place it at a distance from living rooms or provide a soundproof casing, which, by the way, can simultaneously serve as a heater. The station must be rigidly fixed to a concrete base or steel frame. Power supply is required 220 V.

The pumping station has a protection class of 1, therefore, before being connected to the network, it must be earthed (nullified) to ensure electrical safety.

Before starting a new pumping station for the first time, it is necessary to check the air pressure in the accumulator. It should be in the range 1.4-1.7 atm. for small containers up to 25 l; 1.7-1.9 atm. for larger ones. For measurements, a car pump with a manometer is used, it is also possible to pump air through the valve if necessary.

To correctly start the pumping station for the first time, the following work should be done in stages:

To correctly start the pumping station for the first time, the following work should be done in stages:

- Set the station on a firm, level surface, secure.

- Check accumulator. With an empty tank, the standard pressure is 1.5 atm., If more, you need to bleed air through the nipple, less - pump up.

- At the initial suction point, install a check valve on the pipe with a coarse filter mesh, lower it into the water intake. The angle of inclination of the suction line from the pump to the source of 10 degrees or more to the horizontal must be observed. For suction, rigid metal or HDPE pipes are used, as well as reinforced hoses with a diameter of 25-32 mm.

- Connect the suction line to the inlet pipe on the housing.

- Connect the pressure line through the connecting nipple.

- Fill the pump and the suction pipe with water: on the body, open the hole for the inlet, closed with a plug or valve; pour until fluid starts to flow back; close tightly.

- Connect the power cable to a grounded outlet, press “start”.

- Open the nearest faucet to remove any remaining air from the water supply.

- After 3-5 minutes of pump operation, water should pour from the tap. If this does not happen: turn off the station, re-fill the water, restart it.

Duty cycle: the pump pumps a pressure of 3-4 atm. and turns off, turns on only after opening the taps in the house to normalize the pressure in the system again.

It is forbidden to use a pumping station to pump aggressive chemical or flammable liquids.

If the pump station starts up successfully, the automation must be set up.

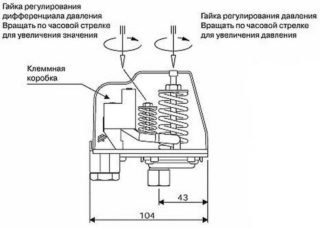

- Disconnect the station from the network, drain the water, open the pressure switch, there are large and small control springs.

- Turn on the pump so that fluid begins to accumulate in the tank. When the pressure rises and the pump shuts off, the pressure gauge will show the upper pressure, write it down.

- To reduce the pressure in the system, open the distant tap or the one located on the top floor. After some time, the relay will connect the pump - the lower pressure will be reflected on the pressure gauge, write down.

Compare the readings with the standard. The standard shut-off pressure is 3 atmospheres or 2.8 bar, the turn-on pressure is 1.5 atm. or 1.4 bar, the interval between the boundaries should be 1.5 atm. (1.4 bar).

If the performance of the pumping station does not differ from the norm, do not change anything.

If the pressure difference is less than normal, to increase, with the pump turned off, slightly tighten the nut on a small spring, to reduce the difference, loosen it.

Too high pressure in the tank will cause frequent on / off. Low pressure will cause the pump to run without stopping. Any option will cause rapid wear of the equipment.

During the test, you can adjust the pressure. Weak pressure in the system leads to the fact that water from the tap flows without enthusiasm - this is uncomfortable for users. To strengthen it, with the station turned off, tighten the nut slightly on the large spring of the relay, to reduce the pressure, loosen it.

Do not immediately immediately change the factory settings of the accumulator up or down. The new unit should work for several days to reveal all the shortcomings.

To ensure that the water supply does not stop at any time of the year, the conduit and pump station should be protected from freezing temperatures, as freezing of water in the system can completely damage the equipment. Such a breakdown is not subject to warranty repair. Therefore, cold water pipes are laid in trenches at a depth below the freezing point of the soil by 0.5 m or equipped with an electric cable for heating. The pump station itself is installed in heated rooms, insulated cellars or sheds, as well as coffers or chambers located below the ground level by 2 m.

When using the water supply system seasonally, only in the warm season, it is necessary to completely drain the water from the pumping station and water supply before frost

After a long preservation of the water supply system, if the house is empty, with the end of the summer season, the airing of the system occurs. Before restarting the pumping station after a downtime or a cold winter, preparatory work should be carried out aimed at cleaning the equipment and displacing the air.

- Clean the filter grid of the non-return valve located on the horizontal section of the suction pipe in the intake. During the downtime of the water supply system, it could become clogged with rubbish or silt.

- Check the functioning of the suction line. To do this, pour water through it from the point of entry into the pumping station to the point of exit into the water intake. Remember to remove the check valve with filter. If there is a problem: an ice plug has formed, the pipe has flattened, cracks have appeared or joints have been depressurized - everything must be eliminated until it is connected, otherwise the pump will not be able to lift water from the well or well.

- Fill the pump and suction hose through the filler port or valve. The filling should be completed only after the water flows over the edge and is established in the neck at a constant level. Close the hole.

- Check the air pressure in the accumulator. If necessary, increase it to the standard by pumping through the valve.

After all the procedures, you can safely start the pump station.

Common errors when starting a station and how to avoid them

When starting the pumping station, problems can arise for various reasons. The most common of them are malfunctions in the engine or pump, for example:

- The engine does not start. Check if it is plugged in. Check fuses, replace if necessary. If the fan wheel does not spin, unplug the engine and turn it with a screwdriver.

- The engine is running, but the water does not swing. It may not have filled the pump with water at startup. It is necessary to turn off the engine and fill the water.

- The unit works without shutting down. The relay may have a higher upper pressure. Must be adjusted.

- The pump turns on and off more often than 20 times per hour. Probable reason: the pressure accumulator in the accumulator is lowered, for example, due to damage to the membrane. It is necessary to replace the part and pump up the pressure to normal.

Sometimes problems are easier to prevent than to fix. If you do not preserve the station in the fall and store it in an unheated room in winter, the remainder of the unfilled water during freezing can damage important parts of the mechanism or water main, in the spring you will have to buy a new station or carry out expensive repairs. Therefore, compliance with operating rules will extend the life of the equipment, significantly reduce costs.