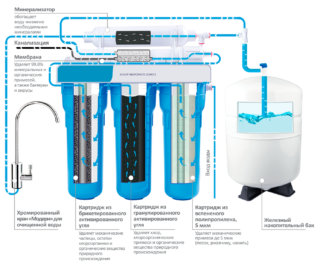

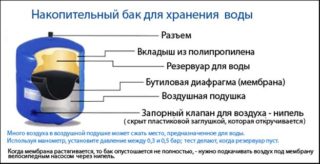

The reverse osmosis filter guarantees the highest degree of water purification. It consists of several coarse filters, a membrane compartment, where reverse osmosis technology is used, and a storage tank, where purified water is pumped to create pressure in the water supply system. The tank, in turn, consists of a steel or plastic case, where a rubber membrane is inserted, which divides the tank into two parts. Purified water is pumped into the upper through the inlet pipe. From it, it is fed into the water supply network. The second in the factory is pumped air. The incoming water compresses the membrane, and it, in turn, presses the liquid under the action of air, creating pressure in the water supply. The technology of creating a water pressure is simple, depending on what pressure the air is pumped into the lower part of the storage tank. The injection is made through a nipple, which is located on the side of the tank below the installation level of the rubber separator.

What should be the air pressure

Standard parameters of air pressure are 0.3-0.5 bar. Most manufacturers adhere to maximum performance. No more can be done. This can lead to automatic closing of the non-return valve, which is installed between the filters and the storage tank. Water passing through the filter will not open it, because its pressure will not be enough to withstand the pressure from the tank.

Standard parameters of air pressure are 0.3-0.5 bar. Most manufacturers adhere to maximum performance. No more can be done. This can lead to automatic closing of the non-return valve, which is installed between the filters and the storage tank. Water passing through the filter will not open it, because its pressure will not be enough to withstand the pressure from the tank.

If the pressure is high, this can lead to rupture of the rubber wall; if insufficient, reverse osmosis technology is disrupted, that is, water will not be filtered. Therefore, it is very important to control the pressure inside the storage tank.

Check the pressure through the installed nipple. You can connect a pressure gauge to it. Experts recommend using an electronic type gauge for checking. He is more accurate. Some people use automobile pumps; their gauge is already equipped with an arrow type pressure gauge. It has a large error, therefore, it will not work to guarantee high measurement accuracy with this device.

If over time the pressure inside the storage tank drops, air can be pumped with the same automobile pump. If a compressor is available, it is best to use it. The main thing is to carry out control, not to allow exceeding the parameter.

Causes of pressure drop inside the water supply network

The very presence of a filter requires maintenance. It mainly consists in timely flushing. Since the reverse osmosis filter includes three coarse cleaning and post-treatment devices, their maintenance consists in replacing the cartridges. If this is not done, the throughput of the devices drops sharply due to contamination of the filter elements.

The very presence of a filter requires maintenance. It mainly consists in timely flushing. Since the reverse osmosis filter includes three coarse cleaning and post-treatment devices, their maintenance consists in replacing the cartridges. If this is not done, the throughput of the devices drops sharply due to contamination of the filter elements.

In order for water molecules to pass through the filter membrane, the pressure in the reverse osmosis storage tank must be at least 3 atm. If an electric pump is included in the package of the filter device, the water pressure in the water supply can be in the range of 1-1.5 atm, because the pump will create the required pressure. But it needs a sufficient amount of pumped liquid. Therefore, a filtering device operating on the principle of reverse osmosis is recommended to be installed in autonomous water supply systems, where water is taken from a well or a well. In such networks, powerful pumps are mounted that provide the required pressure parameters.

Storage tank malfunctions

Often during the long-term operation, the reservoir fails or incorrectly performs its functions.

The first frequently encountered malfunction - water began to leak from the nipple. The reason - the rubber partition is torn. The problem is solved in one way - to change the tank completely to a new one taking into account its volume.

Manufacturers recommend changing the capacity once every 3-4 years. It all depends on the intensity of operation of the water supply network.

The second malfunction - the nipple bleeds air. The problem is solved simply - a failed part is twisted, and a new one is screwed in its place. It is important not to forget to place a rubber or polymer gasket under the nipple, which ensures the tightness of the connection.