The presence of a well on the site is a number of concerns about the operability of pumping equipment. With its proper functioning, water regularly enters the highway. But there are often times when you need to replace the pump with a newer, more efficient one. You can do this yourself or with the help of professionals.

When pump replacement is needed

The fact that it is time to replace the pump in the well is evidenced by such signs:

- The flow rate of the source has changed, and now its performance does not correspond to the technical characteristics of the unit. If the pump is capable of pumping 3 m3 / h, and the flow rate is now only 2 m3, the well will quickly empty out. This is fraught with downtime in the system.

- Broken safety cable or severe slack. As a result, it can entangle pumping equipment and that will fail or damage the casing.

- Long source downtime and difficulty starting up equipment. The pump can simply get silted up with the shaft of the shaft.

- Continuous operation of the pump due to improper selection of the depth apparatus according to the pressure indicators. If the total height to which the device must supply water is greater than the actually indicated in the passport to the unit, the equipment, of course, will pump liquid into the tank, but it will work almost continuously. This will quickly disable it.

- Incorrect immersion depth of the machine. Here, the pump will pump water with sand (at low position) or air will suffice, which will also affect its operation. His position urgently needs to be changed.

If the master found the listed problems with water supply, interruptions in the operation of pumping equipment, this means that it is time to install a new device.

Tools and equipment

To lift the old downhole ECV unit and install a new one, you need to prepare the following tools and equipment:

- powerful flashlight;

- winch (useful with a silted device);

- spanners;

- fittings for connecting a new pump;

- safety cable;

- metal hook;

- new water supply hoses.

It is better to perform the work together or three, in case you have to make efforts to lift the deep device.

Work Stages

To remove the old unit from the well shaft, you need to do the following:

- Disconnect the device from the network. In no case should you try to raise the working unit. This could result in personal injury or equipment damage.

- Disconnect the water supply line from the supply hose, carefully remove the adapter.

- Gently lift the old pump while holding the cable, cable and hose. It is important that none of the elements sag or fall into the casing. This can lead to jamming of the equipment in the mine. If the pump is deep and lowered to a level of 50 m, its total weight with all components, water, and the density of the fluid in the barrel will be about 100 kg. Here you have to work even three together or with the help of a winch.

If everything went well, the pump freely left the casing, in the reverse order install a new device. Pre-connect water supply hoses, a coarse filter and a check valve to it.

Possible problems when lifting the pump

Sometimes difficulties may arise at the time of removal of equipment.In this case, you will have to try yourself or call specialists, which will increase the cost of replacing deep-well pumps in the well.

One of the difficulties is the sagging of the cable or safety cable and further jamming the mobility of the equipment. You can solve the problem if you carefully try to lower the sagging element with the pump together and at this moment gently pull it up. When mobility occurs, the unit is again transported to itself.

The second problem is the siltation of the apparatus. Here you can pull to infinity, but the device will not go up freely. We'll have to rock it on our own. To do this, pull on the safety cable and again, as if to lower it. The back and forth movements are repeated until the equipment is stirred and goes out. With the same problem, one can try to erode the well with a powerful jet of water supplied under pressure deep into the source.

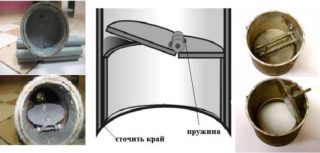

Another problem that the master may encounter is the displacement of the casing trunk or the appearance of protrusions in one of its sections. Here you can try to pull the pump in twisting movements. Carefully bring it up, trying not to stagger the device from side to side.

If the pump stopped at one point and no further, you should fix it in this position and invite specialists. The higher the unit will be in the casing, the cheaper it will cost to extract.

With a dangling safety cable, you will have to use a homemade metal hook. Here you need to act literally by touch. You must try to hook the device to the eye with a hook. As soon as the master feels that the hook is fixed, you need to carefully lift the device. At the same time, it is worth holding the cable and the water hose in parallel. It is important to remember that the safety cable that broke at the top point is an obstacle, the subject of a wedge for the free movement of the unit in the wellbore. Therefore, you need to act extremely carefully. If at some stage the cord interferes with the movement of the device, it is again lowered a short distance down and lifted up. Thus, the cable is given the opportunity to freely reach the bottom of the source and already follow the unit when lifting. If the cable is broken inside the shaft in its lower part, this will create less problems for the master.

Cost of pump replacement

The price of replacing a submersible pump in a well with water, with the assistance of professionals, depends on several parameters:

- depth of equipment;

- casing diameter;

- possible problems (jamming, rupture of the cable, deformation of the column).

In the Moscow region, the cost of such work starts at 15,000 and can reach 65,000 rubles.