Until recently, water-intake street columns were an integral part of the structure of small cities and towns. Their main purpose is to supply water, which was used for domestic needs. These devices were installed on the streets on water supply networks. To mount the device, a well was formed in which the main part of the device was located.

Water Column Requirements

The production of street speakers is based on state standard number 15150. The main requirements relate to the location of the device, and also takes into account the number of consumers.

The production of street speakers is based on state standard number 15150. The main requirements relate to the location of the device, and also takes into account the number of consumers.

- At the location of the water well, the column is installed. If there is no well, it is recommended to build it as close to the sidewalk as possible. The ideal place is a crossroads.

- Consumer coverage is based on: one column per area with a radius of 1000 m.

- Optimally, if the street water intake is formed on sandy soils for easy removal of water into the ground.

- The elevated installation site is better than in the lowland.

- In winter, it is better to insulate the column, because the metal case will not be able to protect water from freezing.

- Installation is carried out on water networks, in which the pressure does not fall below 1 atm.

All fulfilled requirements guarantee long-term and efficient operation of the device. In this case, the depth of the water pipes is necessarily taken into account. Based on this parameter, a device model is selected.

Specifications

The taps made in Russia are strictly manufactured in accordance with GOST. Therefore, they have standard specifications:

- work at a water pressure inside the water supply network of 0.1-0.6 MPa;

- the diameter of the pipe connecting the device to the water supply is 20 mm;

- the diameter of the outlet pipe is 15, or 20 mm;

- vertical stroke of the valve - 16-18 mm;

- the mass of the device with a length of 1.25 m is 31 kg, the weight increase is 2.6 kg for every 25 cm of increase in the length of the device.

The casing of the column is made of steel or cast iron, painted so as not to become rusty. The device itself is a collapsible device, so it is easy to repair. Manufacturers offer any parts and assemblies as spare parts.

Device and principle of operation

A small number of parts are included in the outdoor water column device. The main one is the ejector. With its help, the opening and closing of the water supply takes place:

A small number of parts are included in the outdoor water column device. The main one is the ejector. With its help, the opening and closing of the water supply takes place:

- pipe riser located inside the housing;

- an ejector consisting of three parts: the neck, socket and receiver (sump);

- in the lower part of the device (receiver) there is a cylindrical mesh, the task of which is to filter the water entering the column;

- the column housing is covered by a metal cover in which the lever is mounted.

The column works as follows:

- when pressing the lever, the pipe riser is lowered;

- at the end of the latter, a neck is installed, which is a cylindrical object with a chamfer extended at the end;

- when the lever is pressed, the latter rests against the socket so that the riser does not fall;

- at the end of the riser is a valve, which is located in the lower part of the column - sump (receiver);

- the valve closes or opens the opening of the receiver;

- when you press the lever, it falls down, opening a hole, that is, water moves;

- the riser with the lower end abuts the spring, which is located at the lowest point of the sump, it provides a return stroke of the entire structure;

- when the lever is released, the compressed spring unclenches, raises the riser, the valve closes the hole in the upper part of the sump.

The column design is very simple, so it has been working effectively for many years. Most often, the spring, which is constantly located in the water, fails. It began to be made of tool steel, which is not afraid of contact with moisture.

Sometimes the riser becomes clogged. It is changed to a new one or cleaned, having previously disassembled the column.

The design of the standpipe is unique in that there is never any water left inside the riser. She, with the help of an ejector, enters the housing through an opening in the coupling. Therefore, outdoor devices can be operated at temperatures from -40C to + 40C. This must be indicated in the product passport.

If the riser is frozen in winter, the cause is a drop in water pressure in the water supply system or temperature indicator is below acceptable.

Types of water taps

Manufacturers offer two types of execution, which are labeled as KV and KVO. By technical characteristics, both devices do not differ from each other. The main difference is the way the receiver is attached to the device body.

In KV models, the fastening is done with two bolts that pass through the ears. One is located on the speaker body, the second on the receiver. Between the two nodes, gaskets are installed to ensure the tightness of the structure.

In KVO models, mounting is done using square flanges. One of them is welded to the body, the second to the receiver. Four bolts are used in this design.

Mounting Features

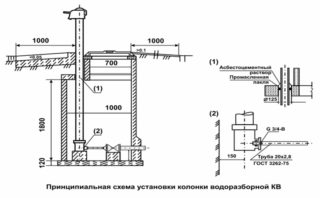

In the receiver on the side there is a pipe with a diameter of 20 mm with an external pipe thread M20. A pipe of the same diameter is attached to it, which is diverted from the water circuit. The connection of the pipe to the water supply system is electric welding.

In the receiver on the side there is a pipe with a diameter of 20 mm with an external pipe thread M20. A pipe of the same diameter is attached to it, which is diverted from the water circuit. The connection of the pipe to the water supply system is electric welding.

A valve must be installed between the column and the supply pipe. The connection is made using flanges or threads. The first option is easier in terms of installation and maintenance. The purpose of the valve is to shut off the water supply and regulate its pressure.

Under the column inside the well, a solid foundation is necessarily laid on which it will rest. To do this, pour a concrete pillow or lay the finished reinforced concrete slab.

Before commissioning, the standpipe is washed with an aqueous solution of bleach. In this way, the device is disinfected. The well is closed with a cast-iron sewer hatch.

Operation and maintenance

Columns need to be serviced monthly. Check for leaks in the ejector:

- in the drain pipe located in the upper part of the riser, a cork made of wood is clogged;

- press the lever;

- water fills the entire volume of the column body;

- the lever is released, and if the water does not increase in volume within 10-20 minutes, it means that the ejector fits snugly into the hole in the receiver;

- pull out the cork, press the lever again and empty the column body completely.

If the ejector is working correctly, in a 175 cm long standpipe, water from the housing will be removed in 5-6 minutes.

If it is necessary to carry out repair work, first of all it is necessary to close the valve, disconnecting the device itself from the water. Next, the cap with the lever is removed, then the riser, after which you can inspect and repair the details of the ejector and sump. Often a grid gets clogged, which you just need to replace with a new one.

Column cost

The prices of street water taps for irrigation and other domestic needs are almost the same for all manufacturers. They depend on the type of execution and the length of the device.

- HF 275 cm long costs 5000 rubles .;

- KVO 275 cm - 4500 rubles .;

- KV 375 cm - 6300 rub.;

- KVO 375 cm - 5700 rubles.

Spare parts are sold separately: spring 240 rub., Mesh 170 rub., Valve - 150 rub., - ejector 515 rub., Receiver assembly - 3500 rub., Receiver not assembled - 1500 rub., Cap - 1800 rub ..

Installing and repairing the standpipe is easy.This should be done by representatives of the water supply organization.