In order for an autonomous water supply system of a country cottage / apartment not to give a surprise in the form of icing in the winter, it is advisable to take care of the insulation of the water pipes in a private house with your own hands. Only in this case it will be possible to talk about the full-fledged work of communication all year round.

Why to insulate water pipes

Uninsulated water supply lines are a number of problems for the owners of the cottage:

- Pipes located at shallow depths are prone to freezing along with soil. The water in them will definitely turn into ice in severe frosts.

- The resulting blocks do not just stop the system, which is extremely inconvenient for the family living in the house, but also often lead to a line break.

- An accident requires laborious and expensive repairs. We have to carry out excavation work, dismantle the pipeline section, finance the installation of a new one.

Thermal insulation of the water supply system is especially relevant for residents of cold / northern regions, where the depth of soil freezing is from 1 to 2.5 m or more.

Necessary tools

To insulate water pipes in the ground at a shallow depth, you should first prepare such tools and materials:

- the selected type of thermal insulation per meter, in accordance with the length of the line from the well to the entrance to the house;

- hacksaw;

- construction tape;

- a shovel;

- sand and expanded clay bedding;

- metal mesh;

- cement mortar, if expanded polystyrene is used as a heater.

Some types of insulation serve rodents in the winter as a heating zone. Animals make holes in the heat-insulating shell, which forms cold bridges on the highway. Condensation forms from them and further freezing of the line. To avoid this, it is recommended to wind a metal mesh over glass wool or expanded polystyrene and then coat the building sandwich with a solution of cement with broken glass.

In preparation for work, it is necessary to draw up a schematic drawing of the main line indicating the insulation materials used and the location of the main components of the system.

The main methods of pipe insulation

The chosen method of thermal insulation of the water supply line depends on the financial capabilities of the master, the desire to tinker with the system, the depth of the pipeline. The easiest way to protect communications from frost is to lay tubes below the level of soil freezing. But for residents of the northern regions this is impossible or extremely costly.

The chosen method of thermal insulation of the water supply line depends on the financial capabilities of the master, the desire to tinker with the system, the depth of the pipeline. The easiest way to protect communications from frost is to lay tubes below the level of soil freezing. But for residents of the northern regions this is impossible or extremely costly.

Power cable

One of the ways to insulate a water supply line is to use an electric cable. You can use both the outer wire and the inner one. The first is mounted easily with your own hands. Internal cable requires a professional approach. The technology of laying it is more complicated.

The energy consumption of such a wire when heating the line is only 10-20 W / linear meter. And the effectiveness of it is 100%.

Cable laying is performed in a spiral with equal pitch. As a rule, it is 10-20 cm, depending on the cross-section of the pipes. The larger it is, the smaller the distance should be. The cable is covered with insulation material from above, avoiding the formation of cold bridges. The construction sandwich is fixed with foil (shiny) tape.

When using an electric cable, pipes can be laid on water no deeper than 50 cm from the ground surface. But you need to monitor the weather. In the coming frosts, it is advisable to include the wire in the mains in advance.

Roll insulation materials

Mineral wool, foamed Energoflex polyethylene or glass wool are the cheapest insulation options. They tend to absorb moisture and eventually lose their airy structure. As an option, some craftsmen additionally cover cotton wool with oilcloth rolls on top. And if you still fork out, you can use a metal casing. It will act as a protective upper shell.

They insulate water pipes with cotton wool according to this technology:

- The line is tightly wrapped with insulating material so that there are no gaps. Mineral wool rolls are fastened with steel wire.

- From above they are wrapped in dense polyethylene, fixing all this with adhesive tape in a spiral.

- It remains to backfill the line.

So that the water does not freeze in the pipes at the exit of the well, it is desirable to build a warmed caisson.

Creating an air gap

This method involves the use of another hollow pipe of larger diameter. A water line is placed in it so that an air gap is formed in the difference in cross sections. It will serve as water protection against frost. Due to the free circulation of air in this zone, the water in the highway will not freeze.

Styrofoam or Styrofoam Shell

Such insulation elements are in the form of whole or split cylinders. The material has the following advantages:

- Density. The insulation will not sag under the influence of static soil pressure.

- Low (zero) percentage of water absorption. The shell does not absorb moisture, does not rot, which means it perfectly retains its heat-insulating properties.

- Affordable for the price.

- Relative ease of installation.

Put the detachable shell on the pipes in this way:

- Arrange the lower part of the material, then the upper.

- All joints are carefully coated with adhesive. Two parts of the shell should be squeezed for a while so that the glue clings well. This is required by the technology of water pipe insulation from HDPE pipes in the ground.

- Subsequent cylinder segments must be mounted with a horizontal seam offset relative to each previous one. This will reduce the number of cold bridges.

When buying thermal insulation in the form of cylinders, you need to precisely select them according to the inner diameter. It should correspond to the outer section of the pipe. Sagging and voids are excluded.

Ready factory pipe

This method of insulation is considered one of the most expensive. The manufacturer offers the master ready-made tubes equipped with heat-insulating material. Structurally, this is one main plastic / polyethylene pipe wrapped with insulation and placed in another (larger in diameter). It remains only to properly lay them in a trench.

If the house is not used in winter, the system can be protected by simply draining water from it. Sometimes masters resort to a radically different solution - they keep the crane constantly open to a minimum. Slow water circulation in the line prevents the line from freezing. But this method is costly. Will have to give all the best for utility bills.

Criteria for the selection of insulation material and requirements for it

The main requirements for good thermal insulation are as follows:

- durability and resistance to chemical / biological environments;

- minimum moisture absorption coefficient;

- low level of thermal conductivity, high heat-saving properties;

- resistance to mechanical / static effects;

- the ability to operate the material at different temperature indicators.

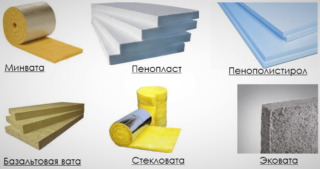

Extruded polystyrene foam, electrical cable, heat-insulating paint, foam in the form of cylinders correspond to such requirements.

In general, you need to choose a heater for water pipes according to the following criteria:

- family budget;

- type of pipe material: for metal, electric cable or heat-insulating paint are good; for HDPE tubes it is better to take polystyrene shell;

- the complexity of the future process of insulation;

- insulation durability: the Penoplex cylindrical segments or finished factory pipes with insulation are considered promising.

Thermal insulation material against freezing of the highway should be purchased with a small margin. This will eliminate downtime and ensure reliable, complete insulation.

Masters Tips

When performing installation work in the country or in a country private house, be sure to pay attention to the joints and fittings. They need better processing. If this moment is missed, condensation moisture will become number one problem over time. Places of threaded joints will be iced up first and then disable the entire system.

Insulation is also required by pipes located in unheated rooms (basement, cellar, etc.). Merilon is best used here.

Do not forget about those areas of the pipeline that are located at the entrance to the house. Here, temperature differences - heat from the basement and cold from the street - are also unfavorable conditions for the normal functioning of the water supply system in frost. Entrance in the foundation zone can also be insulated with Merilon.

A well-arranged water supply system will not cause trouble to the owner of the house and will provide all residents with a continuous supply of water.