In an autonomous water supply system in a summer cottage or in a private house there is a submersible pump that delivers water to the surface of the earth. The main difference between submersible pumps and other varieties is complete penetration into the liquid. To protect the electric motor and reduce the risk of overheating, the working mechanism is designed in a special way.

Purpose and scope of submersible pumps

Submersible equipment is used for pumping any liquids - drinking or dirty water, feces, aggressive liquids in chemical production systems. The requirements for each variety are fundamentally different:

- To raise water from a sand well, protection of the mechanism from the ingress of large particles is necessary. Sand or stones can damage the surface of parts, the device will quickly fail.

- The depth of an artesian well requires a greater height of the water column, so here the main criterion will be power.

- Fecal immersion mechanisms are equipped with special grinders, which form a homogeneous mass during pumping.

- Water is taken from the well by a submersible mechanism with a float.

- If there is a fountain in the design of the site, it is also served by a submersible pump, creating the necessary pressure in the system.

- For watering the garden, it is possible to use river water, which is located at some distance from the house. In this case, filters should be installed on the equipment.

- Lawn sprinklers also require constant pressure, so a small pump is suitable.

- For industrial purposes, submersible equipment is used for the extraction of mineral water, the delivery of sea water or the extraction of minerals in the mining industry. These types of pumps must be corrosion protected so that they can be used for a long time. The same applies to the chemical industry, where acids, alkalis, and alcohol-containing substances are pumped through the device.

As a type of submersible pump, hand-held equipment that does not connect to electricity and works from the use of hand force can be called.

Types of Submersible Water Pumps

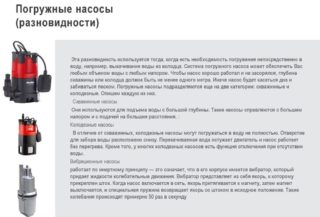

According to the method of operation, submersible pumps are:

According to the method of operation, submersible pumps are:

- vibrating;

- centrifugal;

- screw.

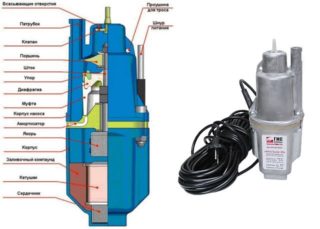

Vibration pumps are the most reliable and durable, because they do not have rotating and moving mechanisms that often break. The principle of operation of vibration equipment is based on the movement of the diaphragm, which bends under the influence of a magnetic field. In this case, water is taken from the tank. Then the diaphragm returns to its original position, while the valve closes and fluid enters the pipe.

The lack of vibration pumps in their sensitivity to voltage drops. With a decrease of at least 10%, the power can be reduced by half. Together with the equipment, it is desirable to purchase a stabilizer that will regulate the voltage.

The advantage of vibration pumps is that they overheat little and rarely break, so they are popular with summer residents.

Centrifugal pumps have proven themselves in narrow wells with a diameter of 12 cm or more. The principle of operation is based on the action of a rotating shaft, on which there are blades and wheels. The shaft creates a movement in which centrifugal force pushes the liquid to the surface.

Centrifugal devices can be single-stage and multi-stage. The latter are able to create more pressure.Distinguish self-priming devices, which begin to work when the body is filled with air. A variation of the centrifugal self-priming pump is the vortex and liquid-ring type. Vortexes do not work long in dirty water, and liquid-ring ones are used where there is a large amount of dissolved air, that is, the pumped water is not homogeneous.

Pumps with a normal suction unit cannot start operation until the casing as well as the outlet pipe are filled with water. If this is not done, the internal mechanism will become unusable and will not be able to pump water. A damaged hose with leaks can interfere with the installation. It is recommended to use a spiral, as it is more resistant to cracks and creases.

Screw (screw) devices are not able to work at great depths. The limit for them is 15 meters, so the area of use is limited by the depth of the well. The disadvantage is the small power, so to provide water to a private house, you will need to choose an expensive and powerful unit. The screw pump device is simple, therefore it serves for a long time. However, water from a sand well is supplied with impurities of stones and dirt.

Advantages and disadvantages

When comparing submersible units with surface units, the advantage of the former is:

When comparing submersible units with surface units, the advantage of the former is:

- minimal noise due to the absorption capacity of water;

- Do not freeze, as the water temperature does not drop below zero;

- all internal parts are cooled by the surrounding fluid, therefore they do not overheat;

- high-performance equipment is used for artesian deep wells.

Disadvantages are present primarily in installation: not all submersible pumps can be installed in deep wells. The design of the unit matters. Some of them - vibrational - lead to rapid siltation of the pipe, since the principle of operation raises dirt from the bottom of the well, subsequently it settles on the walls.

When installing the device, it is necessary to protect the electric cable so that there is no short circuit. For scheduled maintenance, the device must be removed from the well - this may require the help of specialists. In some cases, when the well is too narrow, the submersible pump may get stuck inside, which will require additional work.

Criterias of choice

In order to choose the right pumping equipment for a well or a well, it is necessary to take into account the following parameters:

- Casing dimensions to match the diameter of the pump.

- Well depth. These data are indicated in the documentation left by specialized teams.

- Measure static and dynamic water levels. Dynamic is the distance from the bottom to the surface of the water. Static - from a mirror of water to the surface of the earth. Data is collected after a two-day break in pumping.

- To determine the height of the water column, which is also a selection criterion, the value of the static level is subtracted from the total depth of the well.

- System pressure. For the system to function normally, 3 atmospheres is enough, but losses are observed when water passes through the pipes, as well as in the connecting nodes and valves.

- Performance. To do this, you need to calculate the daily need of the house and the plot in the liquid.

- Water purity. Some models break quickly if solid particles are present in the fluid.

- The presence of additional devices, such as a float, coarse filter or voltage stabilizer. This will help to operate the pumping equipment longer without the need for repairs.

- Brand of the manufacturer and its value.

If there are gases in the liquid, this must be reported at the time of purchase in order to select a submersible centrifugal pump that is capable of working with water of such quality. This applies primarily to mineral springs with a natural gas level.

Installation and Connection Steps

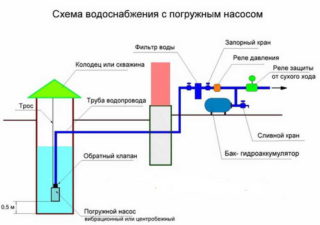

The connection of the deep pump to the water supply system begins after the preparation of the well - drilling and installation of the casing. It is necessary to wait a day so that the mud settles to the bottom and does not interfere with testing the equipment in operation.

The connection of the deep pump to the water supply system begins after the preparation of the well - drilling and installation of the casing. It is necessary to wait a day so that the mud settles to the bottom and does not interfere with testing the equipment in operation.

You can prepare the equipment yourself, having previously studied the procedure:

- A pipe is attached to the outlet. The junction is additionally wrapped with tow or special tape. This is necessary in order to maintain a vacuum and prevent leaks that make the equipment work for wear.

- A hose and a check valve are attached to the suction part. It prevents the discharge of water.

- A coarse filter is attached to the end of the valve so that sand does not enter the pump housing and does not create friction.

- The electric cable is attached to the discharge element with clips.

- The kapron thread that will hold the pump in the well is tied on brackets.

- The unit lowers down to the required level and is fixed in this position at the top. Usually they leave 1 meter from the bottom, so that when consuming water there is no idle situation.

The most common mistakes that non-professionals make are incorrectly selected cable cross-section that does not correspond to the pump capacity, as well as the absence of a backflow valve. Incorrect determination of the water level can lead to rapid breakdown from overheating of the unit and increased friction of parts without liquid. If the house experiences constant power surges, this can lead to loss of power and poor water flow into the system. To do this, install a stabilizer or storage tank.

Saving on water supply is not recommended for several reasons. One of them is the constant repair and lack of water in the house. The most popular equipment is imported. The price of an electric water pump 12 volts for a home well of foreign brands is about 25 thousand rubles. The service life of such a device is up to 10 years without the need for repair.