The installation of a water well on a site of concrete rings is one of the popular ways to create autonomous water supply in a private house. Such structures are inexpensive to execute and convenient to use. If you want to build a structure of this type is possible independently.

Standards and requirements

When choosing a place for the construction and installation of hydraulic structures, you must strictly adhere to the rules of SNiP 2.04.02-84. According to them, the distance from the well shaft should not be less than:

When choosing a place for the construction and installation of hydraulic structures, you must strictly adhere to the rules of SNiP 2.04.02-84. According to them, the distance from the well shaft should not be less than:

- five meters - to the foundation of the house;

- four meters - to buildings for animals and garden trees;

- meter - to shrubs and garden beds;

- meter - to any outbuildings in the territory.

Septic tanks or cesspools are located at a distance of at least 50 meters from the water intake structure. At the same time, treatment facilities cannot be located higher in relief than water wells.

According to building codes, the well shaft should be covered with a lid. This is necessary to prevent water pollution in the structure by precipitation, and also to ensure the safety of children and animals.

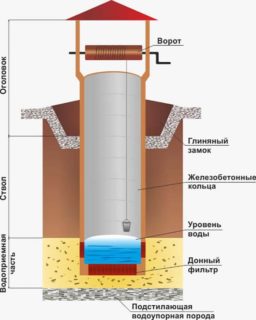

In order to avoid the penetration of surface water, the water intake device is mounted so that its top rises on the earth's surface by at least 0.5 m.

Materials and Tools

When building a home well for drinking water from concrete rings, it is easier to use the services of professionals, but you can build a hydraulic structure yourself. However, you will have to work hard, since reinforced concrete products are rather heavy. Tools must be assembled:

- level;

- roulette wheel;

- winch;

- shovels;

- buckets;

- trowel.

For work, concrete rings themselves, waterproofing and sealing building materials, will be needed. It is rational to make a well for drinking water from elements with a section of up to 100 cm and a height of 25–50 cm. To lower or rotate a larger element, the use of special equipment will be required. To facilitate work on the pit, they put a tripod. With its help, it is more convenient to take out the soil and lower the reinforced concrete elements.

Installation of a well device

The construction of the structure can be done in two ways. The first of them - with the installation of rings in turn. It will require a shovel with a short handle - otherwise it is impossible to work inside a rather narrow circle. The essence of the method is that the rings will sink into the pit as it is dug up.

Installation steps:

- Dig a hole with a diameter slightly larger than the selected rings to a depth of about half a meter.

- Install the first reinforced concrete element there. It is important that he stands exactly in the center of the shaft, without abutting against the walls.

- Continue digging the soil inside the concrete product.

- Install the second ring when the top edge of the first is level with the ground. Brace items.

- So repeat until water seeps through the bottom of the shaft. Continue to take out the earth by pumping out the accumulating water.

- Finish digging when you reach the first water layer. Continue to pump out water to level the bottom and create, if necessary, a bottom filter.

Sometimes it happens that the ring element does not fall. The reason is simple - it stands on a slope. You can fix this by putting the shield up and scattering stones or bags of soil on the side that you want to lower. When the ring begins to sink, the load is removed.

There is another method when the rings are alternately placed in a shaft completely dug up to the water horizon.But this is not possible on all types of land: there is a chance of a sudden collapse of the mine before laying. In addition, it is difficult to do it manually. As a rule, the rings are lowered into the pit by a crane, mounted one on the other end to end and fixed by means of steel brackets.

Well shaft waterproofing

Insulation is carried out during construction from the inside and outside. An external one is needed to prevent dirty tops from entering the well. To this end, create the so-called clay castle. The upper rings are dug in a trench about half a meter wide and 150–200 cm deep. Clay is poured into it and densely packed. It turns out a clay slope from the well to divert precipitation.

Internal will help to avoid depressurization of the mine. All inter-ring seams are coated with a special compound. When sealing them, do not forget about cracks and depressions, since they quickly collapse under the influence of water, which will lead to depressurization of the well.

The use of bitumen solutions is prohibited, as they can adversely affect the taste of the liquid.

The construction is being completed by concreting the site around the mine, installing and decorating the head, and installing pumping equipment and filters. To create a head, the last ring should be projected 0.6–0.8 m above the soil level.

If you follow the technological process of equipping a water well, the result is a long-term and easy-to-use source of clean drinking water without significant costs.