Earthworks, despite their simplicity, are considered the most difficult process. Auger drilling is a way to facilitate and accelerate them while minimizing the risk of rock collapse. High-tech equipment allows for the development of almost year-round, regardless of weather conditions.

What is auger drilling

In regions where soils with low hardness prevail, preparation of the trunk for installation of water intake equipment causes many problems. Therefore, when drilling sand and sand and gravel soils with a depth of up to 60 m, and sometimes more, use the screw method. The design of the equipment is represented by several elements.

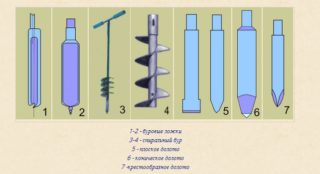

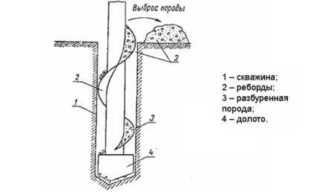

- The auger is a device that is a metal pipe with a drill head-chisel and screw-shaped iron plate-flange to divert the destroyed soil to the surface. The product is prefabricated and consists of several, interconnected during the operation of the elements.

- The bit is fixed at an angle from 300 to 600 to the bearing axis. The looser the soil, the less angle you need to set. When passing through hard gravel-pebble rocks, it is recommended to use a head with high-strength technical diamonds. The cross section of the well usually does not exceed 600-800 mm, but in case of exclusion, the use of screws of 1500 mm or more is allowed.

- During prolonged work, the device heats up, as a result of which the rotational process is reduced. Therefore, more and more often, the auger for drilling wells has a feed channel through which water or air entering the cutter cools it. However, in general, the process of lowering the temperature occurs due to the contact of the head with destructible soil.

- The tool axis is made of medium-carbon alloy steel of increased strength and weldability. Screw blades made of high manganese steel are attached to the pipe by welding. The cutting part is made of carburized high alloy steel, which allows to increase hardness, avoiding the appearance of brittleness.

- If it is necessary to drill to great depths, special mechanisms with a rotator are used, the speed of which depends on the diameter of the well: with a large one it varies in the range of 100-250 rpm, and with a small one it reaches 500 rpm.

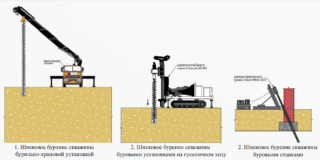

- Auger well drilling with LBU 50 type machines is often used in conjunction with the casing method or with plugging technology. Such designs make it possible to strengthen the well at the same time as sampling the soil by installing rock-retaining walls and thereby prevent collapse. In addition, mines made using these technologies do not require flushing.

- Drill head with auger can be both separate and integral. The combined version is called auger. The main requirement for the equipment is its reliability, mobility and transportability.

The auger method is mainly used in the construction of wells with a low amount of fluid intake or for the formation of shallow wells. In the first case, mechanized labor is used, and in the second, manual labor can be used. In addition, this method is common in engineering and seismic surveys of hydrogeological surveys when searching for minerals.

Auger Drilling Principle

The basis of the method is a rotational action, which, depending on the upcoming scope of work, is performed manually or mechanized.

- When choosing equipment, it is taken into account that the flange is intended only for transportation, so the diameter of the bit or drill should be 20-40 mm larger than the cross section of the screw. With constant drilling at high speed, the centrifugal force presses part of the soil against the walls of the shaft, compacting them, which contributes to the formation of a slurry crust.

- The workflow should take place with a minimum of interruptions. To increase torque and increase productivity, the equipment is mounted on the chassis.

- The technology of auger drilling of wells, performed by machines of the LBU 50 type, includes: cooling the working tool, transportation to the surface of the destroyed soil, strengthening the walls of the mine. The use of mobile installations reduces the loss of time when changing the location of the drilling site. Using this equipment allows you to dig up to 200 meters with a section of 190 mm. The presence of a hammer allows the formation of a well with a diameter of 550 mm.

- To start the auger into action, it is necessary to bring it into place and put it into working position by lowering the support shoes. After this, drilling occurs. The directional movement of the auger at high speeds is ensured by the rigid design of the installation. As you dive, additional sections join.

- When drilling a hole with your own hands using a home-made drill and additional devices of industrial production, the technological process does not change. The only difference is the dimensions of the mobile device, as well as a depth limit of 60-70 meters.

The method of screw drilling allows you to make a pass in the vertical, horizontal and inclined planes. The technology involves the use of a hydraulic station. When performing work, the walls are simultaneously cased with metal pipes. The rest of the process is identical.

Advantages and disadvantages of the method

According to statistics, the cost of producing wells using auger drilling is the lowest, the speed of putting them into operation is the fastest. However, this method has both pros and cons.

In addition to the speed of execution of work, the positive aspects include the simplicity of equipment and a simple technological process, which allows homeowners to carry out small work and get to deeply buried aquifers independently. The tool is easy to install and allows for quick replacement of worn parts. There is no need to spill the shaft of the shaft during drilling and to remove soil without removing the tool. A plus can be considered the lack of the need to engage in prolonged pumping of the well when it is put into operation. Clay, sand and other impurities in the trunk are practically absent, the filters of the water pumps are not clogged, reclamation is not needed.

The negative sides of the technology is also enough. The main ones are the restrictions on the depth and width of the well, as well as the lack of the possibility of drilling in any soil. Even if the soil parameters correspond to technological requirements, the presence of large stone on the drill path may lead to the need to change the site. In addition, during operation, there is a large load on the tool drive and its dismantling or breakdown may occur. That is why the application of this method is most common in regions with close occurrence of potable water and with weak soil. The disadvantages of screw wells include a small influx of water, which may not be enough to meet the needs of a large family.