Well plugging or plugging is a set of measures aimed at protecting drilling hydraulic structures, for example, artesian wells, from biological and chemical pollution of the aquifer, the destruction of concrete casing rings. When conducting an autonomous water supply system, artesian wells are most often constructed, and they need regular grouting.

Purpose and definition of well plugging

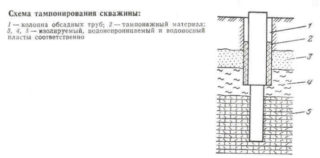

Tamponing is a technological process, the main task of which is to block and disconnect the aquifer with a protective pad. This protective “barrier” is made of cement mortar. The space between the earthen shaft and the water intake trunk is subject to cementing. In the form of a tampon, molten plastic or clay with auxiliary building ingredients is often used.

The main purpose of the procedure is to prevent possible contamination of the aquifer and to protect pathogens from entering it. Grouting is carried out in the following cases:

- Decrease in the quality of well water with insufficient insulation of the aquifer.

- Deformation or fracture of concrete casing rings.

- No need to operate a water intake point.

- Prevention of mixing of different water horizons, for example, with a high concentration of metals and salts with fresh, etc.

- Detection of geological and / or technical malfunctions.

- Prevention of pollution of the source, provided that drilling and construction took place with gross violations.

- Decreased productivity of the water intake and the inability to create a new one

Well plugging is recommended when searching for new sources, as well as to prevent the entry of overheads into it.

Types and technology of carrying out

In practice, two types of grouting are used:

In practice, two types of grouting are used:

- Constant. Characterized by filling the gap with cement mortar.

- Temporary. The procedure is accompanied by the fact that the gap is filled with clay mixtures.

The first method is designed to operate the well shaft for a long time. For example, the average life of an artesian well reaches 50 years or more. The second is used when a new well is required to test and remove specific gaps between aquifers or the seams themselves.

The temporary type of plugging is also liquidating for sources of small depth with no pressure.

Technology of cementing and liquidation

With the complete elimination of the source, cement mortar is poured into the mine - this reduces the likelihood of mixing adjacent aquifers, and also strengthens the trunk.

There are different variations of cementing, the compositions used have significant differences. Which solution to give preference depends on the hydrogeological characteristics of the source.

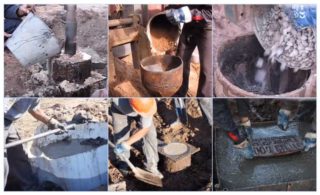

The main building mix is Portland cement. When mixed with water, a liquid solution forms, which can be easily transported using a water pump. Within a short time, it becomes impenetrable and solid. The prepared mixture is poured into a mine working approximately three meters high. Sand and gravel are also added to the grouting solution until a liquid state is obtained. If there is a gliding of aquifers, a gap is filled with a solution, flooding between pipes.

High-quality grouting is carried out using a clay press.A column of clay is placed in the face with a shell for the column. This column is squeezed out using a water pump. The projectile is equipped with a number of holes for draining excess solution, they are also made to reduce pressure.

The technology of plugging consists in filling the gaps between the column or wall of pipes with a clay or cement mixture. Work is carried out at a depth where an aquifer lies. Also, bleach is added to the solution for disinfection.

Advantages and disadvantages

The technological process is widespread, since it has a rather extensive list of advantages:

- Improving the sealing of the joints of concrete casing rings and strengthening the structure as a whole.

- Implementation of additional waterproofing.

- Prevention of penetration into the artesian well of drains and tops.

Of the shortcomings, it is worth noting the financial, physical and time costs. Specialists recommend the liquidation plugging to be trusted by professionals, since the procedure requires the use of special equipment and machinery. Protective grouting can be carried out independently.