An autonomous water supply system requires pressure equipment. With its help, the water supply is carried out in full. For narrow wells it is better to use submersible pumps. The devices made in the form of a flask are ideally placed in the casing without damaging its walls. Thanks to the optimal technical characteristics of the Aquarius submersible pump, it is possible to raise water from any depth (wells to limestone or sand).

The device and principle of operation of the pumps Aquarius

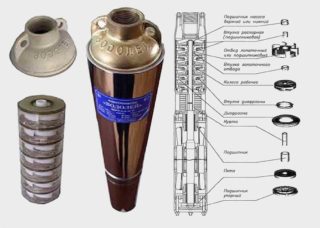

Well pumping equipment of the Kharkov plant "Promelectro" has a similar structure regardless of model. The main working elements of the unit:

- Electrical engine;

- coarse filter;

- capacitor box;

- centrifugal wheel with blades and drive.

The pump works according to this principle:

- When connected to the network, the engine starts the operation of the centrifugal rotor blades.

- It, in turn, creates kinetic energy, which absorbs water through the inlet pipe and scatters it along the walls of the flask.

- The liquid gradually rises into the upper receiving chamber and then enters the water pipes.

- In place of the left water comes under pressure a new portion from below.

Centrifugal blowers, unlike the vibrating two-valve BV, operate carefully, gently, without sharp fluctuations. Do not destroy the casing of the well, do not lift small grains of sand from its bottom.

Lineup and Specifications

Aquarius pumps have an extensive lineup. Modifications are designed for different parameters of wells. The main technical characteristics of each type of unit are contained in its name. This allows the user to navigate in a variety of models.

Example: BTsPE 0.5-100U 60/150 pump. Decoding:

- BTsPE - household centrifugal submersible electric pump;

- 0,5 (l / s) - equipment productivity;

- 100 - head in meters;

- 60 - maximum maximum productivity in liters / minute;

- 150 - the height of fluid transportation at maximum pressure.

In total, Promelectro produces four groups of centrifugal apparatuses, each of which also has its own line of 8-9 models:

- Submersible Aquarius (NVP) pumps with a capacity of 0.32. You can choose a pump for a well of different diameters.

- In the BTsPE 0.5 category there are 8 modifications of units. All of them have a difference in terms of pressure (from 16 to 100 m). In addition, they can work from manual or automatic control.

- Pumps from the category 1.2 l / s is a line of 8 models. They differ in pressure (from 12 to 80 m).

- A group of equipment with a capacity of 1.6 is considered the most powerful. The pumps here differ in terms of pressure (25, 32 and 40 m), as well as structurally (they have from 6 to 8 stages of the pump part).

To accurately select the desired Aquarius model, it is desirable to calculate the well flow rate and the approximate water consumption per family per day.

Advantages and disadvantages

The main advantages of submersible units Aquarius:

- relative noiselessness unlike vibrational;

- economical consumption of electricity;

- compact dimensions;

- wear resistance of brass, stainless and polymer working elements;

- fully equipped, which allows you to immediately mount the equipment.

All Aquarius pumps have the international safety standard IEC 335-1 and are warranted for 1.5 years.

How to choose a pump Aquarius

When buying a deep-well screw pump Aquarius, the choice should be based on such criteria:

- cross-section of the casing (as a rule, it is from 4 inches or 100 mm);

- water mirror in the well;

- source flow rate;

- distance from the well to the water supply points (length of the pipeline);

- estimated fluid flow per family;

- pressure in the damper compartment.

It is advisable to ensure that the technical characteristics of the equipment do not exceed the capabilities of the well. The operation of an overly productive device will lead to the fact that the source will not have time to fill up. As a result, it will drain and then turn off the pump.

Installation and connection

In order to fully install the pump and ensure its uninterrupted operation, you can understaff the system with a 50-100 liter hydraulic accumulator and a head that will protect the source shaft from debris entering it.

In order to fully install the pump and ensure its uninterrupted operation, you can understaff the system with a 50-100 liter hydraulic accumulator and a head that will protect the source shaft from debris entering it.

Installation of the unit in the well is carried out in several stages:

- It is necessary to mount a check valve. It will prevent water from flowing back from the pipeline into the chambers of the device. They fix the valve immediately at the outlet of the working chamber of the equipment into the pipe, just above the pump itself. It can be mounted at a distance of up to 1 m from the unit. It is important to pay attention to the arrow on the check valve. It always shows the direction of water flow. You need to place an element with the up arrow. If you do it differently, the valve will work in the opposite direction, will not let the liquid into the receiving pipes.

- Fix the pump to a strong cable. It is advisable to use kapron rather than steel. The second option, under the influence of moisture, will eventually fail, rust, tear.

- In parallel with the cable, an electric cable and a water supply pipe are launched, which are mounted to the equipment outlet pipe. It is advisable to fasten all three elements along the length with clamps, duct tape in increments of 40-50 cm. This will prevent sagging of the cable or cable. Remember, it is forbidden to fix a safety cable and a cable to a pull. It is advisable to measure their free position.

- Once all the elements of the unit are assembled, it is possible to lower Aquarius into the casing to the marked depth. It is forbidden to install the device on the bottom. The minimum distance from the lowest point of the well to the pump is 1 m.

- It remains to connect the equipment to the network. A voltage of 220 V is required for its operation. If with such an indicator of a problem, it is better to install a stabilizer.

Continuous operation of the pump and its shutdown in automatic mode indicate that the installation has been completed correctly.

Operation and maintenance

Judging by user reviews, the Aquarius unit works without failures. However, it is necessary to carry out its preventive maintenance, which consists in regular activities:

- replacement of bearings in hard running;

- motor winding test;

- oil change;

- checking the pump for sand blockages;

- coarse filter replacement;

- checking the tightness of the pipeline.

- washing the elements of the working shaft.

It is advisable to perform such actions at least once a year. If necessary - more often.

The price of a submersible pump for the Aquarius well depends on its technical characteristics. On average, in the Moscow region a centrifugal unit for a well can be paid from 1,800 to 27,500 rubles.

Owner reviews

Nikolay, 35 years old. A year ago, he built a house on his site and finally drilled a well on the sand. I tried to pump it with a vibration pump. He suffered for about two months. The sand was of course becoming smaller, but it did not disappear completely. Then the neighbor suggested that it is better to put a submersible centrifugal unit. I bought Aquarius BCPE 0.5-25 U. After its installation, by the evening the well began to give completely clean water. The device is quiet. Performance is enough for my wife and I.

Yura, 41 years old. We have a well on the site a long time ago. Although the house has a central water supply. But literally in the last months of something, water began to be supplied to the village very poorly. We decided to pump out of the well using a vibration pump.In about a month of such operation, we prettyly dug one of the concrete rings of the well. We came to the conclusion that you need to put a centrifugal submersible unit. The choice fell on Aquarius. Now we don’t know the problems. The water mirror in the well is 5 m, and the distance to the house is only 18 m. It lacks both pressure and productivity.