In autonomous water supply systems, expansion tanks of different volumes are used. When they are included in the water supply system, it is possible to reduce the number of cycles for turning on and off the equipment and thus extend its service life.

Purpose of expansion tanks for water supply

The purpose of expansion tanks is to maintain constant pressure in the water supply system of a private or apartment building. Depending on the needs of residents, you can choose the right tank volume.

For the plumbing system, the greatest danger is water hammer. This is a sharp change in pressure in the pipes. There are positive water hammer when the pressure rises sharply, and negative, in which case it drops. If positive, breakthrough of pipes from any material is possible, after which replacement will be required and the house will not be cut off from the water source for some time. More than 60% of cases of damage to the trunk are due to positive water hammer. This happens as follows: when the tap was opened in the house, a certain amount of water was used, then it was closed, the liquid in the pipes continues to flow by inertia in the direction of the tap, collides with the partition and starts to flow in the opposite direction. There are two waves - oncoming and reverse. They collide and burst the pipe.

The use of a diaphragm tank prevents this situation, since the pump is turned off in advance, at the signal of the pressure sensor. The fluid speed is no longer so high and is not able to damage the pipe material.

Using the expansion tank, you can create the necessary supply of water. The engine will not turn on again until the pressure inside is normal. In the event of a power outage, water will enter the house under the pressure that is created in the system.

In some cases, the membrane tank is installed in an apartment autonomous system to reduce the pressure of the centrally incoming water. The pressure of cold water can be so strong that pipe connections in the heating system begin to leak. The membrane tank is a kind of obstacle and does not allow more liquid to enter the apartment than the boiler and pipes can withstand.

Thanks to the correct settings, you can achieve almost the same water pressure. If the owner of the equipment is interested in the long-term operation of the pump, he will configure the sensors so that they operate less frequently, but the pressure may temporarily decrease. In a private house, this leads to the fact that a person in the shower can get burned with hot water, because the cold pressure will decrease.

The principle of operation and device

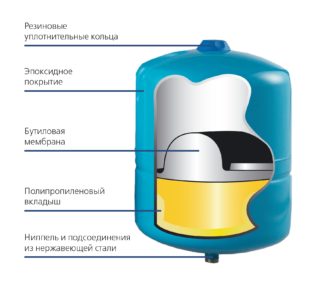

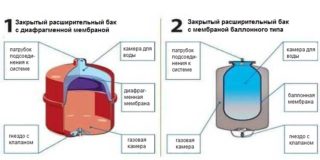

The membrane tank consists of a metal casing, which inside is treated with a corrosion-resistant coating. It is divided into two parts, one of them is a rubber bulb, where water is collected, the other is filled with air.

When the liquid begins to flow, the pear expands and the air pressure inside increases. When the sensors fix the upper limit, the pump turns off, water enters the house under pressure. With a large flow of liquid, the equipment turns on again, as the pressure drops and the water pressure weakens for a short period of time. You can adjust the unit so that the pressure is always the same, but this will lead to more frequent starts and wear of the equipment.

The accumulator can be used separately, for example, if a submersible deep-sea pump is installed. Also, the accumulator is included in the set of pumping stations. Their main disadvantage is that they raise the liquid from a maximum of 8 meters. If the water mirror drops lower in the summer or for other reasons, you have to lower the immersion hose below. At the same time, the pump does not have enough power to raise the liquid up. In this case, the upper pressure limit cannot be reached in the system and the station operates without shutting down. This sometimes leads to overheating of the equipment and the electrical winding burns out. Changing it is expensive and disadvantageous, therefore, it is recommended to buy a new pump.

Installing a submersible pump and a separate diaphragm tank is cheaper than buying a station with an ejector. Firstly, such equipment is very noisy during operation, and secondly, it is expensive.

The bulb is mounted internally with a threaded flange. If necessary, it can be replaced. On the other side of the casing there is a special nipple through which the amount of air can be regulated using a bicycle pump. If you click on the nipple, excess volume will come out. Some models use a nitrogen mixture.

Types of tanks

In addition to membrane tanks, there are those in which there is no rubber bulb. The principle of operation is the same - the balance of liquid and air inside, but at the same time they are mixed. Such containers are less durable, since sooner or later the water damages the inner surface, and it rusts. In expensive models, the inner wall is coated with anti-corrosion paint. Such containers need to be serviced more often, since part of the air is usually mixed with water and leaves through pipes, as a result of which the air pressure gradually decreases. Once a season, a mandatory check of the pressure level and air pumping is necessary.

In addition to membrane tanks, there are those in which there is no rubber bulb. The principle of operation is the same - the balance of liquid and air inside, but at the same time they are mixed. Such containers are less durable, since sooner or later the water damages the inner surface, and it rusts. In expensive models, the inner wall is coated with anti-corrosion paint. Such containers need to be serviced more often, since part of the air is usually mixed with water and leaves through pipes, as a result of which the air pressure gradually decreases. Once a season, a mandatory check of the pressure level and air pumping is necessary.

There are tanks that can withstand only cold water. They are made of rubber, which withstands temperatures from - 10 to + 50 degrees. Rubber is suitable for drinking water, as it does not emit harmful substances.

The storage tank for hot water systems can withstand temperatures up to 120 degrees. The material of manufacture is butyl synthetic rubber. Also suitable for drinking water.

For the accumulation of process water, another brand of rubber is used. Temperature indicators are similar to the previous ones.

The case can be made of stainless steel or durable plastic. The first varieties are more expensive, but more durable. Outside and inside are covered with paint.

Criterias of choice

First of all, the tank is selected based on the amount of water that can be stored there. On sale there are tanks from 24 to 1000 liters. In this case, the volume of liquid occupies only 30% of the total. This is necessary in order to build up the necessary pressure.

A feature of small tanks is the lack of a nipple to remove excess air. This may cause inconvenience during operation. Large tanks are better at maintaining a constant pressure in the system, have a nipple and are more versatile in maintenance.

Depending on the available area for installing the storage tank, you can choose a horizontal or vertical model. In horizontal volume is always less, they can be mounted on the wall. Vertical have legs for installation, the volume of fluid in them is greater.

In addition to these two indicators, the choice is made taking into account the following criteria:

- pressure that can be created in the system thanks to the membrane tank;

- is it possible to periodically change the membrane or is it non-removable;

- whether it is possible to store drinking water or rubber is intended only for technical fluid;

- case material - steel or plastic.

For a family of 2 to 3 people, a capacity of up to 25 liters is enough. If there are more people and a pump is installed, which pumps about 3.5 tons of water per hour, you can put a capacity of 50 liters.With a very high flow rate, for example, in an apartment building, a tank of 100 l is suitable.

Installation Steps

Sometimes, in addition to the main tank, installation of smaller containers is required. In this case, the displacement will be calculated taking into account all the tanks included in the system.

Sometimes, in addition to the main tank, installation of smaller containers is required. In this case, the displacement will be calculated taking into account all the tanks included in the system.

After choosing a model, you must be guided by the rules by which the installation is carried out:

- the pipe diameter must be the same or larger than the tank inlet;

- fittings are used collapsible;

- it is necessary to choose the right place so that it is convenient to carry out repair work;

- the metal case is grounded;

- the tank is installed closer to the pump, between them there should be no other equipment capable of increasing the pressure in the system.

Installation steps:

- Installing filters on the pump, which will pump water from the well. This is necessary so that sand does not accumulate in the membrane and does not wash it.

- A five-pin part is installed, to which a manometer, relays and protection sensors will be connected, as well as a ball valve, overlap and tee.

- The container is mounted on the wall or mounted on the legs and screwed with anchor bolts.

- A flexible eyeliner connects the tank and the five-pin part.

- A pressure gauge and sensors are installed.

It is advisable to provide for the possibility of draining the water in case of emergency repairs.

Operation and maintenance

Before commissioning, settings must be made. To do this, completely drain the water and measure the pressure with a manometer. If it does not meet the required, using a car pump it is brought to the desired performance. The difference in maximum and minimum pressure should be within 1.5 bar.

Maintenance is carried out in order to check the pressure in the air or gas compartment. New containers do not require a detailed inspection. In older systems, the housing may crack or break the integrity of the membrane, which will have to be replaced.

The prices of a membrane expansion tank for water supply depend on the materials of manufacture, the brand of the manufacturer, as well as the potential amount of water that can be stored inside. The kit may include mounting parts, pressure gauge and dry running relays.