Laying a water pipe by puncture is a method of trenchless installation of a pipeline under various obstacles - roads, buildings. Its essence is to form the required diameter at a given depth of the channel by forcing it through pipes, working bodies of special machines and mechanisms, and a high-pressure water jet. This method is used both when laying main water supply pipes, and for installing water supply in the private sector, in a summer cottage.

Types of punctures

Depending on the mechanisms used, the principle of laying a channel for laying pipes, the following types of puncture are distinguished:

- punching;

- horizontal directional drilling (HDD);

- brown screw drilling;

- hydraulic puncture;

- vibration piercing.

For convenience, two pits (pit) are excavated at the opposite ends of the trajectory of the pipe being laid - the initial and final.

Punching

This type of puncture is performed as follows:

This type of puncture is performed as follows:

- A directional drilling installation is placed in the initial pit, consisting of a frame with hydraulic cylinders that drive the carriage with a drill string - rods interconnected.

- The first in the carriage is a rod with a working head in the form of a sharp cone.

- Using the oil station (gasoline engine with oil pumps), the hydraulic cylinders force the first rod into the wall of the pit.

- After most of the first rod has disappeared into the soil, the carriage is pulled back with the help of hydraulic cylinders. At the end of the rod with the help of a threaded connection, screw the next one, fix it in the carriage and repeat the process of forcing.

- When the working head of the first rod of the drill string appears in the final pit, it is removed, a fixture for fastening and pulling the pipe is installed.

- Pulling the pipe fixed to the first rod, it is laid in the channel (case) drilled in this way.

When laying a polyethylene water pipe in the winter during the broaching phase, it is heated by a blowtorch or burner. This is necessary so that the polyethylene becomes more flexible, does not crack and does not deform when passing through a channel drilled for it.

Horizontal directional drilling

This method is widely used when laying water networks with a diameter of up to 200 mm. The puncture is carried out by special self-propelled installations on a caterpillar track, capable of working in conditions of limited space and fuzzy soil.

This method is widely used when laying water networks with a diameter of up to 200 mm. The puncture is carried out by special self-propelled installations on a caterpillar track, capable of working in conditions of limited space and fuzzy soil.

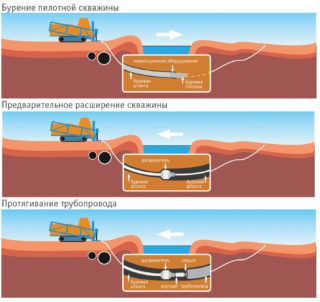

The technology of horizontal directional drilling consists of the following stages:

- Drilling a pilot well - at the same time, the installation deepens the rod string with the working drill head in the form of a blade on the first of them at a given angle and pierces a narrow channel, reaching the surface or in the wall of the final pit at the end point of the pipeline laying trajectory.

- Sequential expansion of the pilot well - at this stage, the working head is replaced by a special rotating expander (rimmer), which, when pulling the rod string, increases the channel diameter to the required value. At the same time, new drill rods are attached to the end of the trimmer - this is necessary so that after expanding the channel, it is possible to quickly and easily stretch tubing through it.

- Pulling the pipeline - a swivel (earring) is installed on the last rod connected to the rimmer, to which the head of the pipe whip is connected. The pipeline is drawn by selecting the rods by the installation until the end of the pipe appears at the starting point of drilling.

The size (diameter) of the trimmer and the extended well should be 30 mm larger than the diameter of the pipe that is placed in it.

In the process, a special composition is introduced inside the drill string and on the tip (working head), which contributes to the destruction of the drilled rock, to reduce the friction of the rods against the soil, and to remove the drilled rock from the well. After completion of the work, the drilling composition collected in the pit is pumped out, cleaned of rock particles and, with the help of chemical reagents, regenerated for subsequent use.

Rock drilling

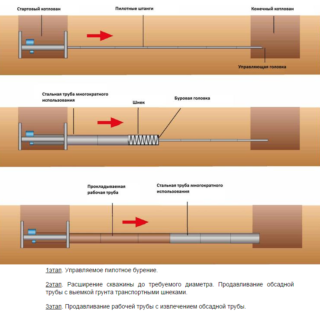

This method of trenchless laying of plumbing and other communications is as follows:

This method of trenchless laying of plumbing and other communications is as follows:

- Inside a large pipe-case, a screw is installed, rotating from the installation engine, with a working head (blades) in the end part.

- When pressed by installing the pipe into the wall of the pit, the rotating auger drills the rock it encounters on its way and partially removes it through the pipe end.

- After the first pipe has completely disappeared into the soil stratum, the next pipe with the same screw inside is attached to it;

- When the end of the pipe string appears in the final pit, all the screws with the remains of the rock drilled and not removed by them are sequentially removed from it.

Several water supply lines are placed in a pipe drilled in this way.

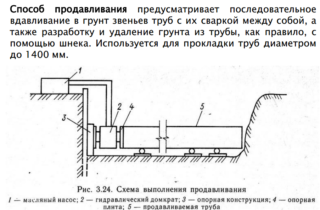

Hydraulic piercing

This type of puncture is carried out by means of a horizontal drilling installation, in which a special head is put on at the end of the first rod of the drill string, punching the soil stratum in front of him using a powerful jet of water created by a centrifugal pump.

This type of puncture is carried out by means of a horizontal drilling installation, in which a special head is put on at the end of the first rod of the drill string, punching the soil stratum in front of him using a powerful jet of water created by a centrifugal pump.

This method is used to puncture loose sandy and sandy loamy soils.

Vibro-puncture

In case of vibration penetration, the working body of the pneumatic punch, in addition to rotational movements, also performs powerful reciprocating (like a jackhammer). Due to this, such plants can quickly and accurately pierce even the most dense clay or loamy soil.

Method Advantages

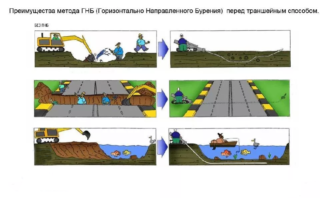

The popularity and relevance of this method of laying a water pipe is explained by such advantages:

The popularity and relevance of this method of laying a water pipe is explained by such advantages:

- Efficiency of work performance - compared with digging an open trench, a puncture takes 3-4 times less time.

- Low laboriousness - a puncture does not require significant physical effort and a large number of workers, as is the case with the trench method of laying pipes.

- Year-round - puncture of soil under the water supply using various installations can be performed at any time of the year.

- Environmental friendliness - this method of laying the pipeline avoids disturbance in the soil structure, damage to tree roots, destruction of natural landscapes, artificial lawns and plantings.

- Low risk of damage to nearby communications (sewers, communication lines, gas pipelines) - with a puncture, the likelihood of damage to nearby communications is much less than when excavating with a bucket of an excavator or trencher.

- Low cost - even when hiring specialists with special equipment, digging up a sewer with a puncture method is 30-40% cheaper than with a traditional trench laying.

Do-it-yourself puncture under the water supply in stages

You can make a puncture underground for the water supply yourself, without involving specialists and contractors, with its length not exceeding 30 m. Such works, except for the acquisition of materials, will not cost their executor a dime, not only saving money, but also gaining useful experience in laying communications puncture.

Materials and Tools

When doing a puncture of the road for a water pipe with your own hands from materials, only a steel thick-walled pipe with a diameter of 40 mm with a sharp pyramidal or tapered tip is welded.To make such a working body better from durable tool steel - fragile material, found in the soil with solid inclusions, layers of clay, can quickly fail, being deformed.

Of the tools for this work, you will need:

- bayonet shovel;

- scrap;

- sledgehammer;

- Bulgarian.

Puncture stages

Simple puncture technology under a road or other obstacle consists of the following steps:

- Digging two trenches on either side of an obstacle. At the same time, the trench from which the puncture will be made should be dug 1.5–2 meters more than the distance that is planned to be pierced under the obstacle. This is necessary for the convenience of working in a trench with a heavy sledgehammer.

- Laying a punching pipe at the bottom - with the help of a level and bricks, the pipe is laid exactly in the center of the trench, resting the tip of the tip against the wall of the thickness of the soil that needs to be punched.

- Punching a layer of soil under an obstacle - blows of a sledge hammer on the end of the pipe, it gradually deepens into the soil stratum until its tip appears in the trench on the other side of the obstacle. After that, the tip and flattened by the blows of a sledgehammer, the end face is cut off with the help of a grinder.

The pipe is removed from the puncture directly when laying a water pipe in it so that the earth around the done channel does not collapse and does not fill it.

Cost of work

The price per meter of puncture of the soil stratum under the obstacle for laying the water pipe depends not so much on the amount of work, type of soil, but on the length and diameter of the punched channel. So laying 1 meter of a water pipe by the method of horizontally directed drilling will cost an average of 1300-1600 rubles to the customer. When installing water supply pipes under roads, buildings and other obstacles by horizontal drilling, hydro- or vibro-puncture, the cost of 1 meter will be slightly lower - from 1000 to 1200 rubles.